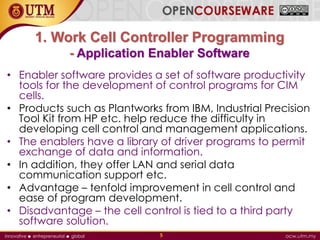

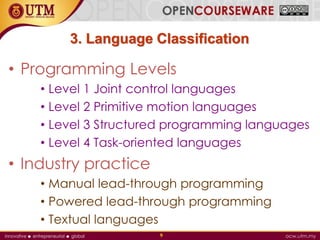

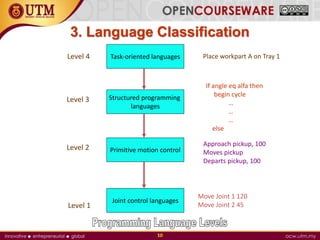

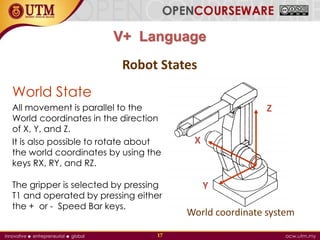

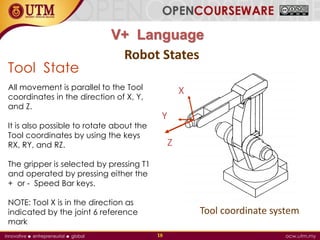

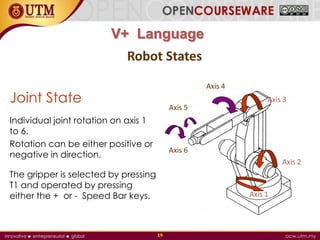

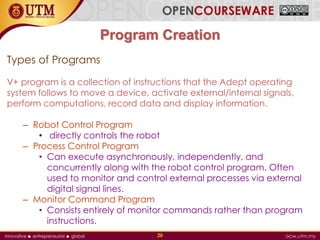

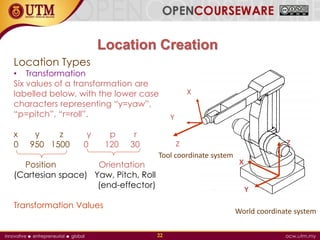

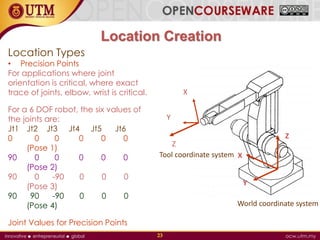

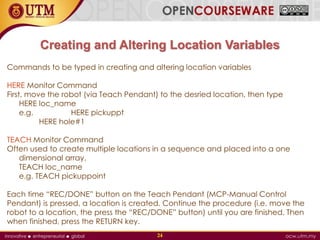

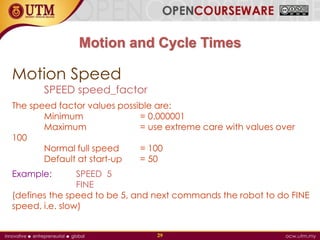

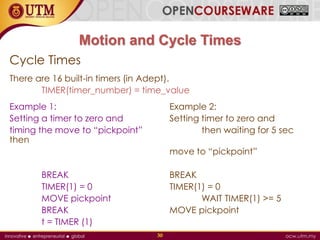

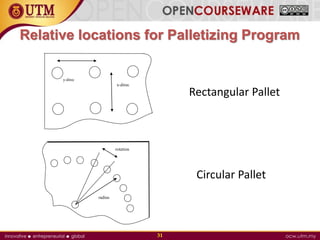

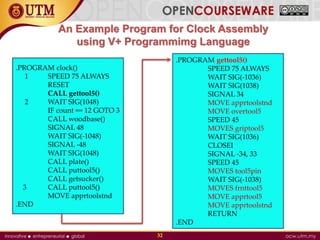

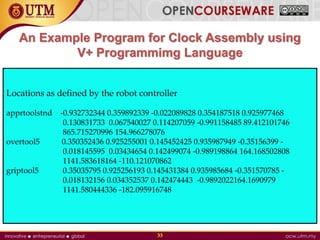

This document discusses robot technology for automation and robot programming. It covers topics like work cell controller programming, programming sequential cell activity, robot language development, robot program fundamentals using the V+ programming language, and provides examples. It describes the different types of work cell control software, robot programming languages by level from joint control to task-oriented, and common motion instructions. Sample V+ programs for clock assembly are also included to demonstrate concepts like locations, motion, and cycle times.