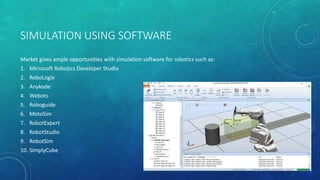

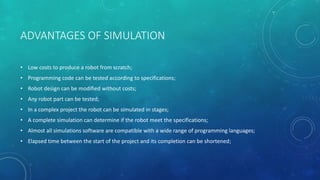

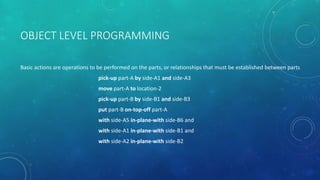

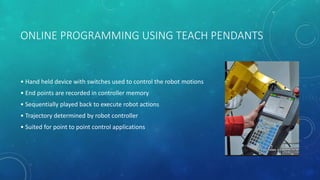

This document discusses simulation and programming of robotic positions. It describes using simulation software to test robotic systems virtually before implementing them in the real world. This allows exploring design options while avoiding risks to the physical robot. The document also covers different types of robotic programming including joint-level, robot-level, and high-level programming. It compares online and offline programming methods and discusses advantages and disadvantages of techniques like teach pendants and lead-through programming.