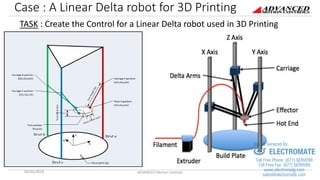

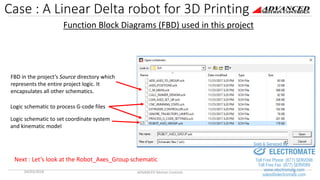

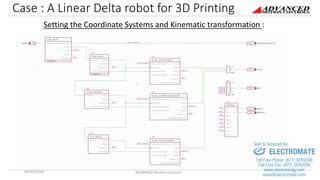

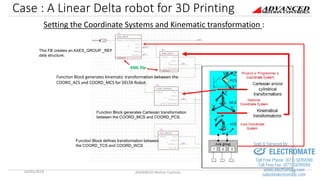

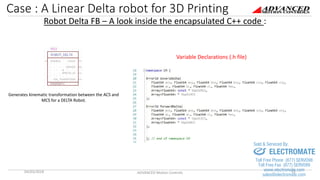

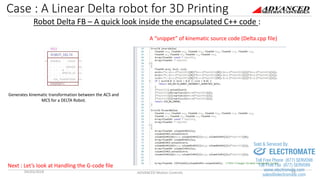

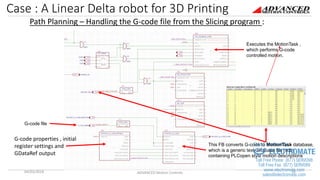

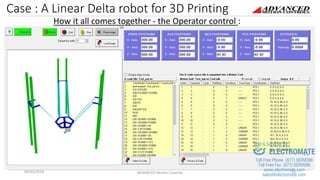

This document discusses the development of control software for a linear delta robot used in 3D printing. It describes using PLCopen function blocks and XML files to create reusable software components for robot kinematics and handling G-code from slicing programs. Function block diagrams are created to process G-code, set coordinate systems, and represent the overall project logic. The solution involves creating user-defined function blocks to handle the robot's inverse kinematics and translate G-code commands into motions.

![Case : A Linear Delta robot for 3D Printing

Definitions (cont.):

- Linear Delta Robot (LDR) : is a type of parallel robot manipulator in which

three prismatic (sliding) joints ( 1 DOF) move separate arms (translate them)

which connect to a single triangular end plate [1]

- Forward Kinematics : System of equations which can determine an end

effector’s position based on the position of the robot actuators. [2]

- Inverse Kinematics : Equations used to calculate the necessary actuator

positions to move the end effector to the desired position. [2]

04/03/2018 ADVANCED Motion Controls 4

sales@electromate.com

www.electromate.com

ELECTROMATE

Toll Free Phone (877) SERVO98

Toll Free Fax (877) SERV099

www.electromate.com

sales@electromate.com

Sold & Serviced By:](https://image.slidesharecdn.com/advancedmotioncontrols-roboticssymposiumpresentation-openstandardtoolsforroboticcontrol-180403190150/85/Advanced-motion-controls-robotics-symposium-presentation-open-standard-tools-for-robotic-control-4-320.jpg)

![Case : A Linear Delta robot for 3D Printing

04/03/2018 ADVANCED Motion Controls 17

Citations :

[1] R.Clavel , “ Device for the positioning of an element in space “ U.S. Patent # 4.976.582 , Dec. 11 , 1990

[2] S.Kucuk and Z.Bingul, Industrial Robotics: Theory, Modelling and Control , Berlin 2006

sales@electromate.com

www.electromate.com

ELECTROMATE

Toll Free Phone (877) SERVO98

Toll Free Fax (877) SERV099

www.electromate.com

sales@electromate.com

Sold & Serviced By:](https://image.slidesharecdn.com/advancedmotioncontrols-roboticssymposiumpresentation-openstandardtoolsforroboticcontrol-180403190150/85/Advanced-motion-controls-robotics-symposium-presentation-open-standard-tools-for-robotic-control-17-320.jpg)