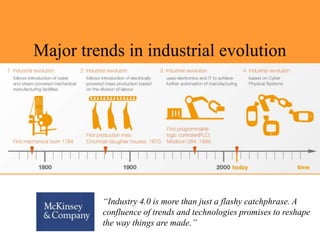

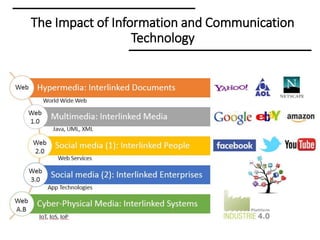

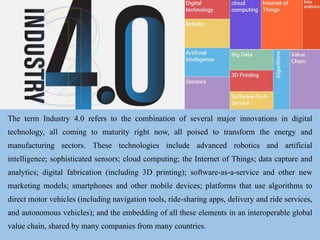

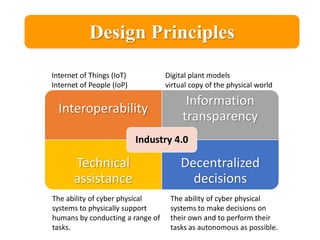

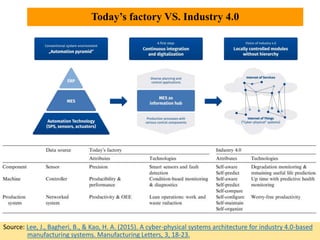

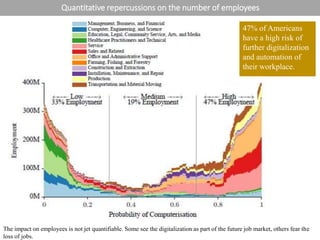

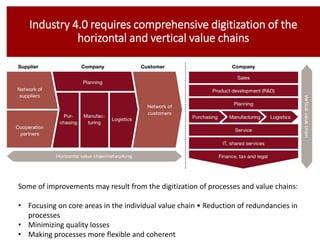

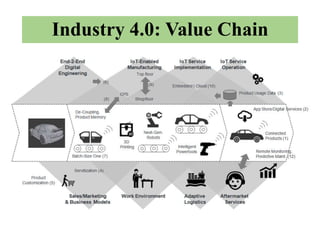

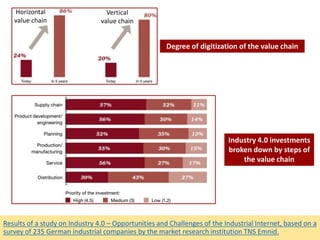

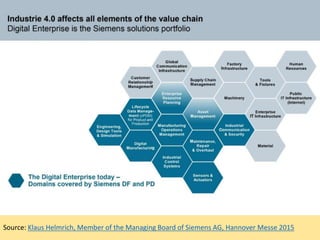

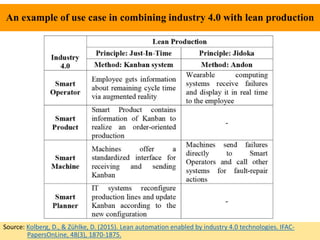

The document discusses Industry 4.0, which refers to the combination of digital technologies transforming manufacturing, including robotics, AI, sensors, IoT, analytics, and more. It describes how these technologies are poised to reshape manufacturing through interconnected global value chains and smart factories. The document outlines the main Industry 4.0 principles of interoperability, transparency, assistance, and decentralized decisions. It also discusses the impacts on employees, value chains, investments, and use cases combining Industry 4.0 with lean production. Experts comment that Industry 4.0 has great potential through data-driven applications tailored for customers to automate processes and monitoring.