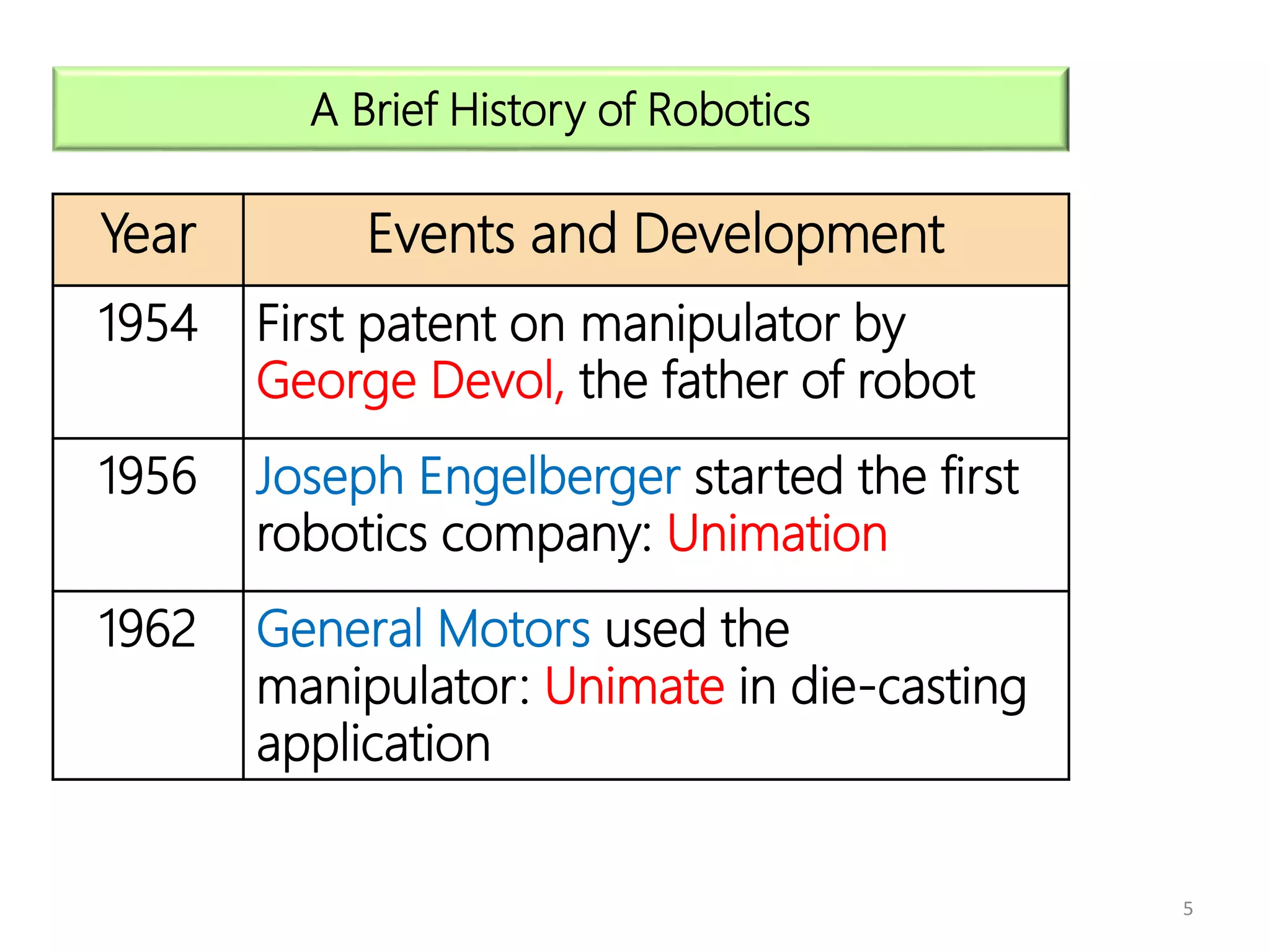

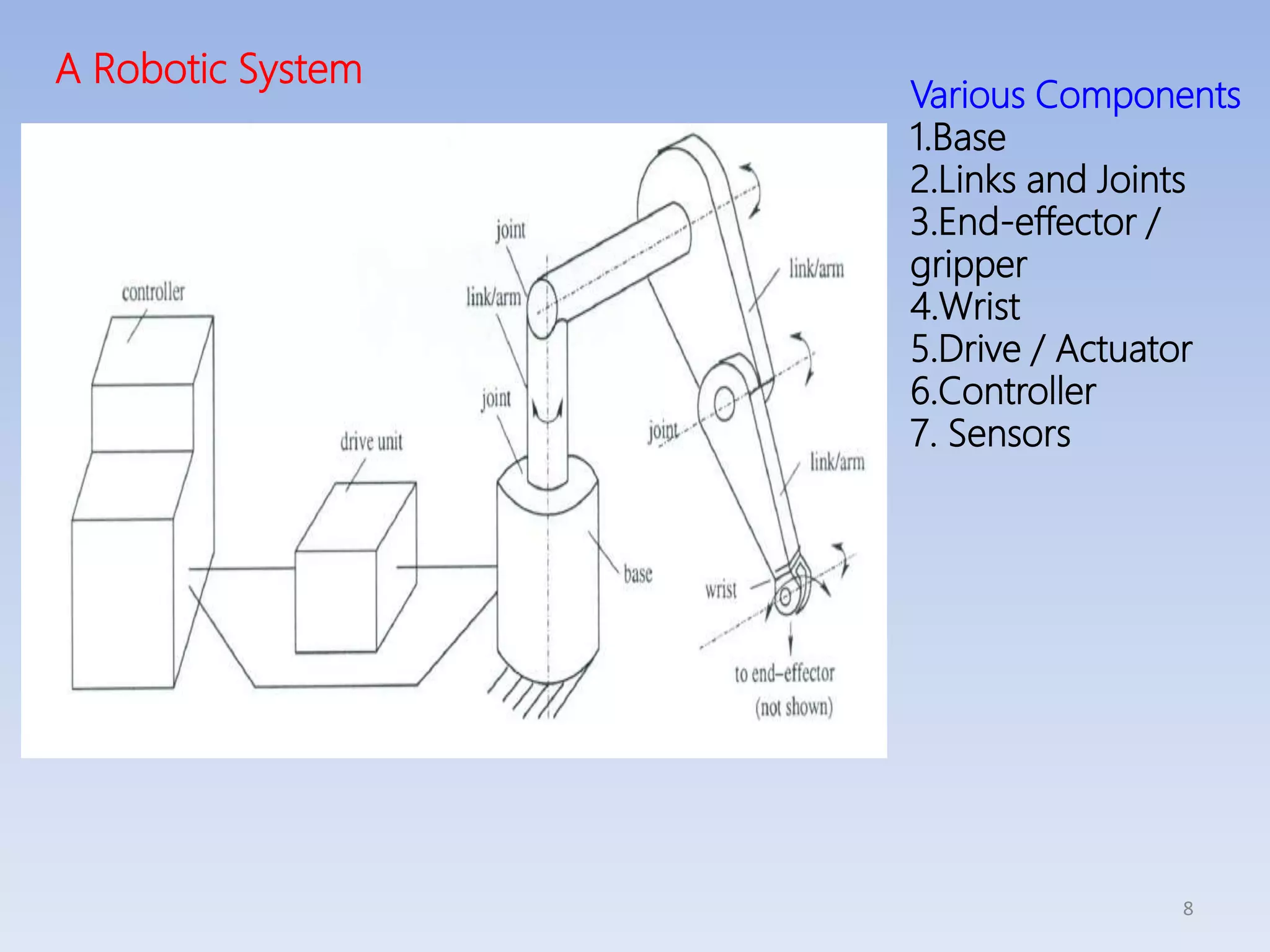

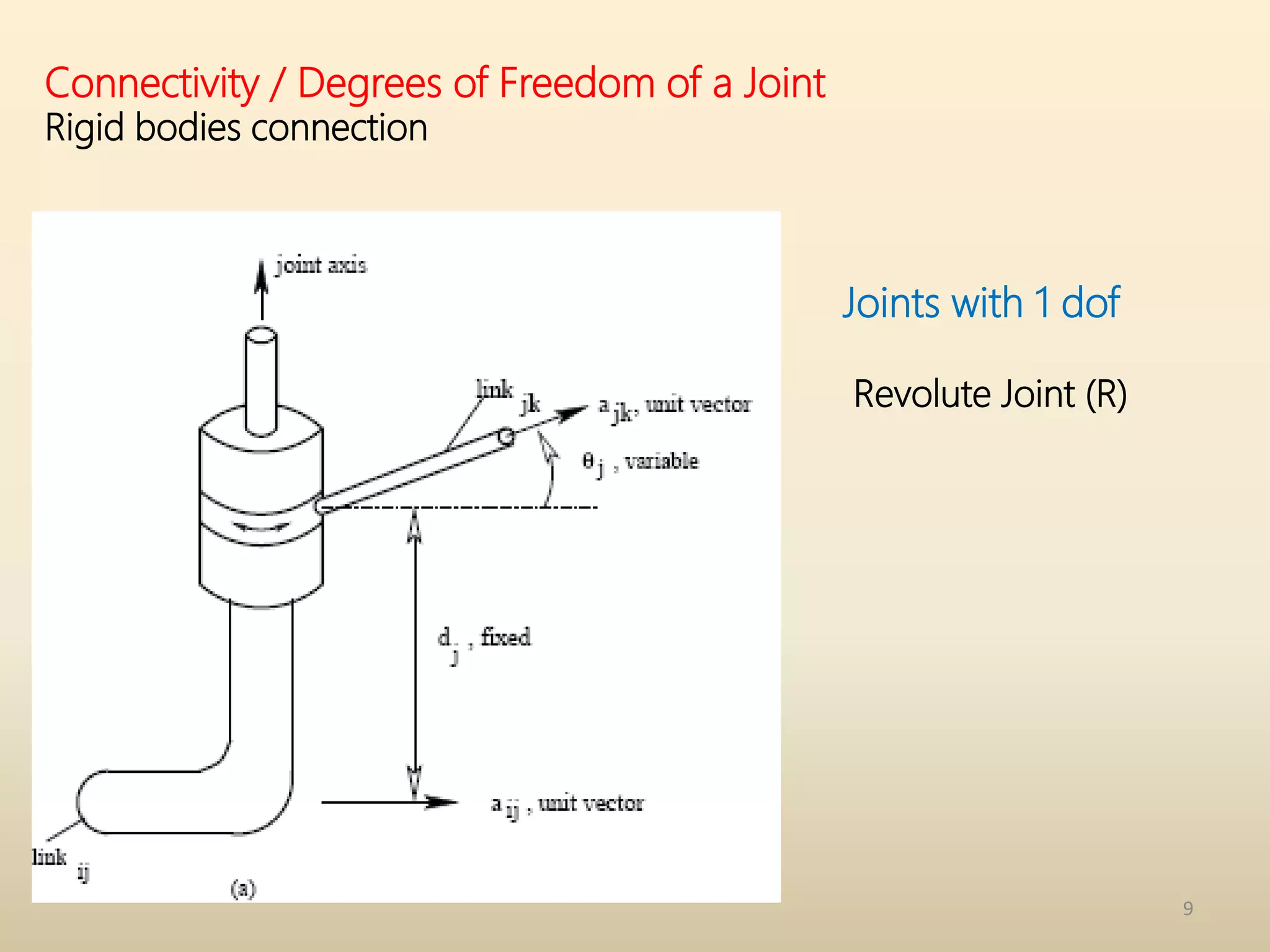

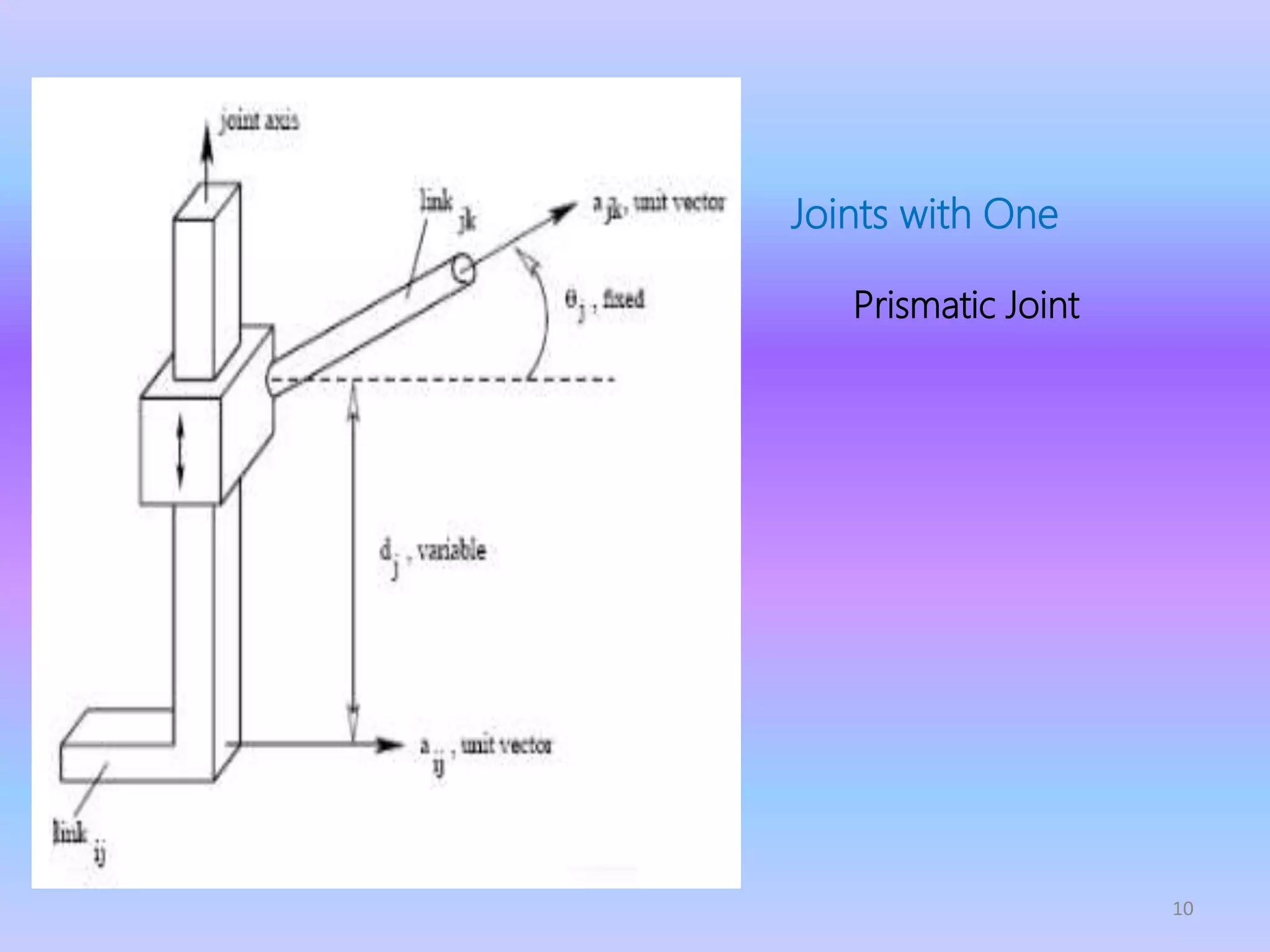

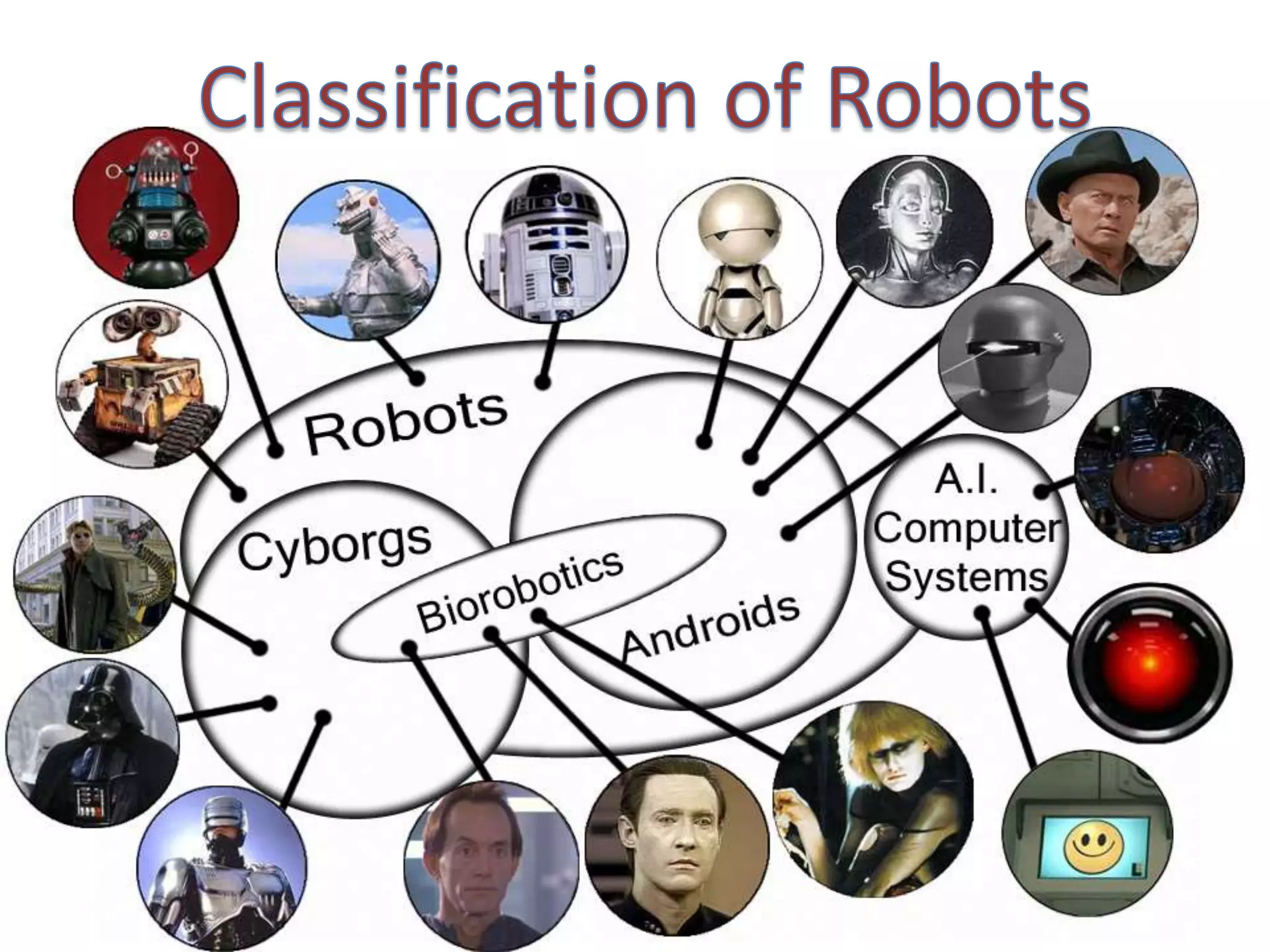

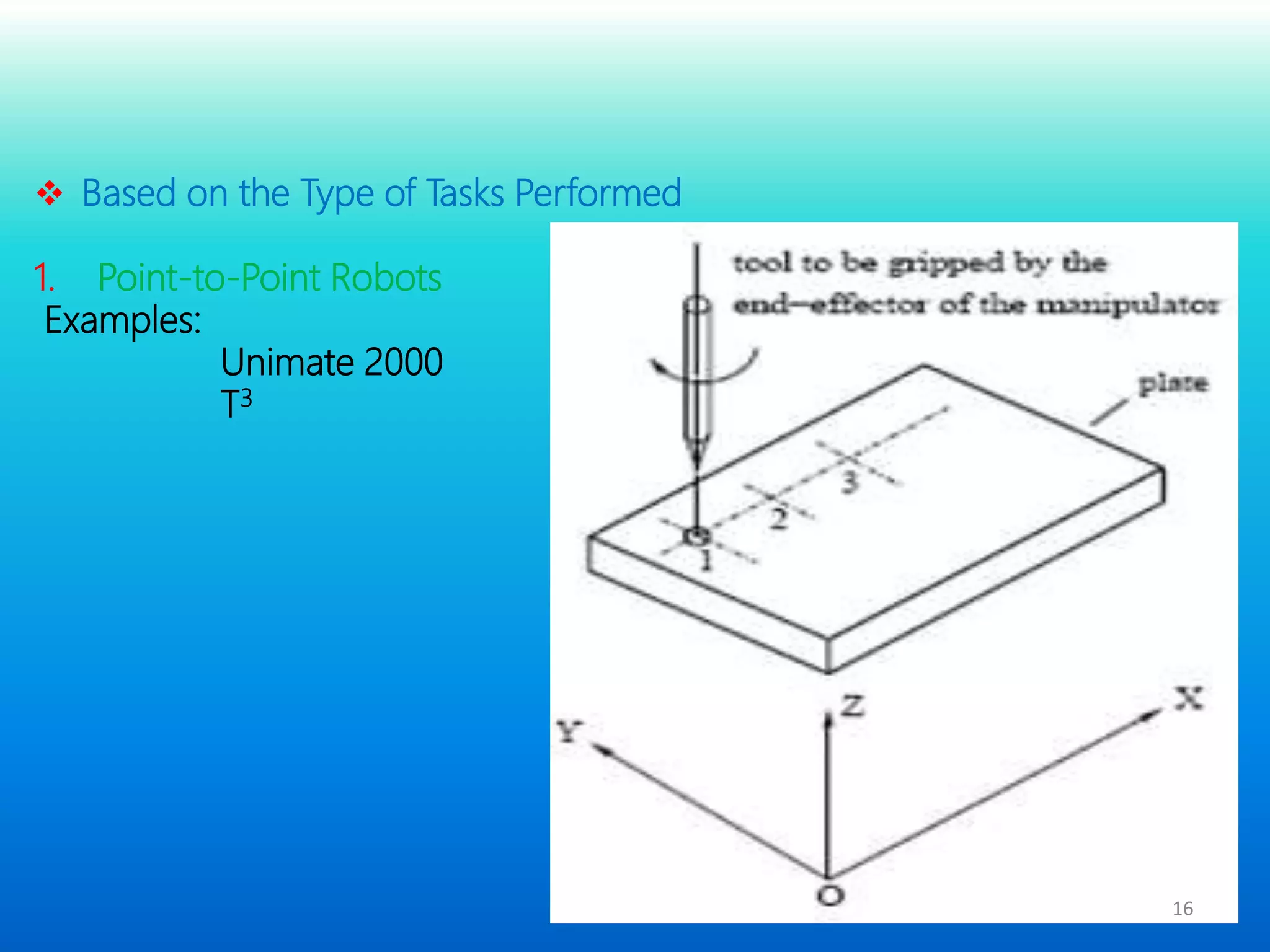

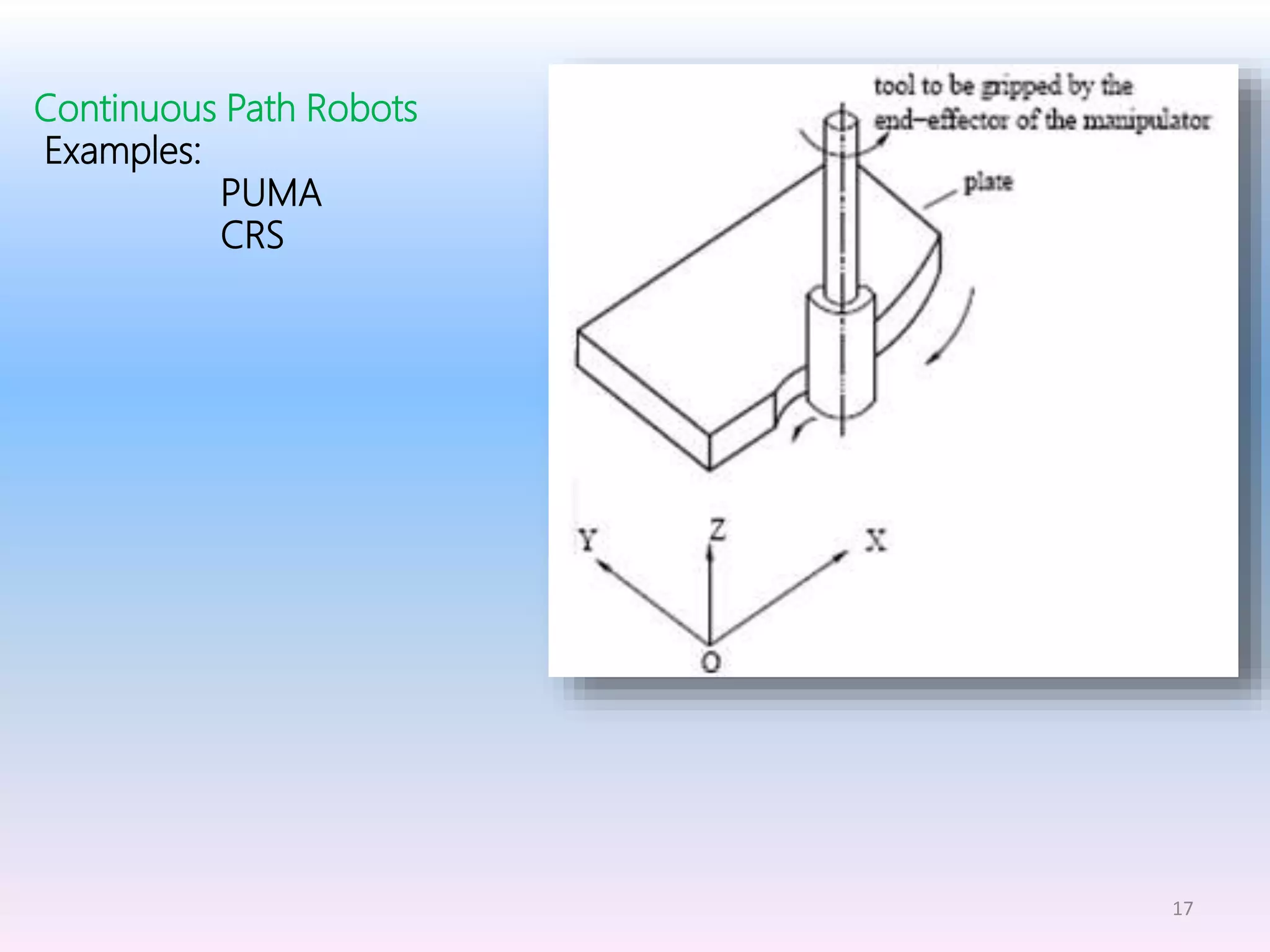

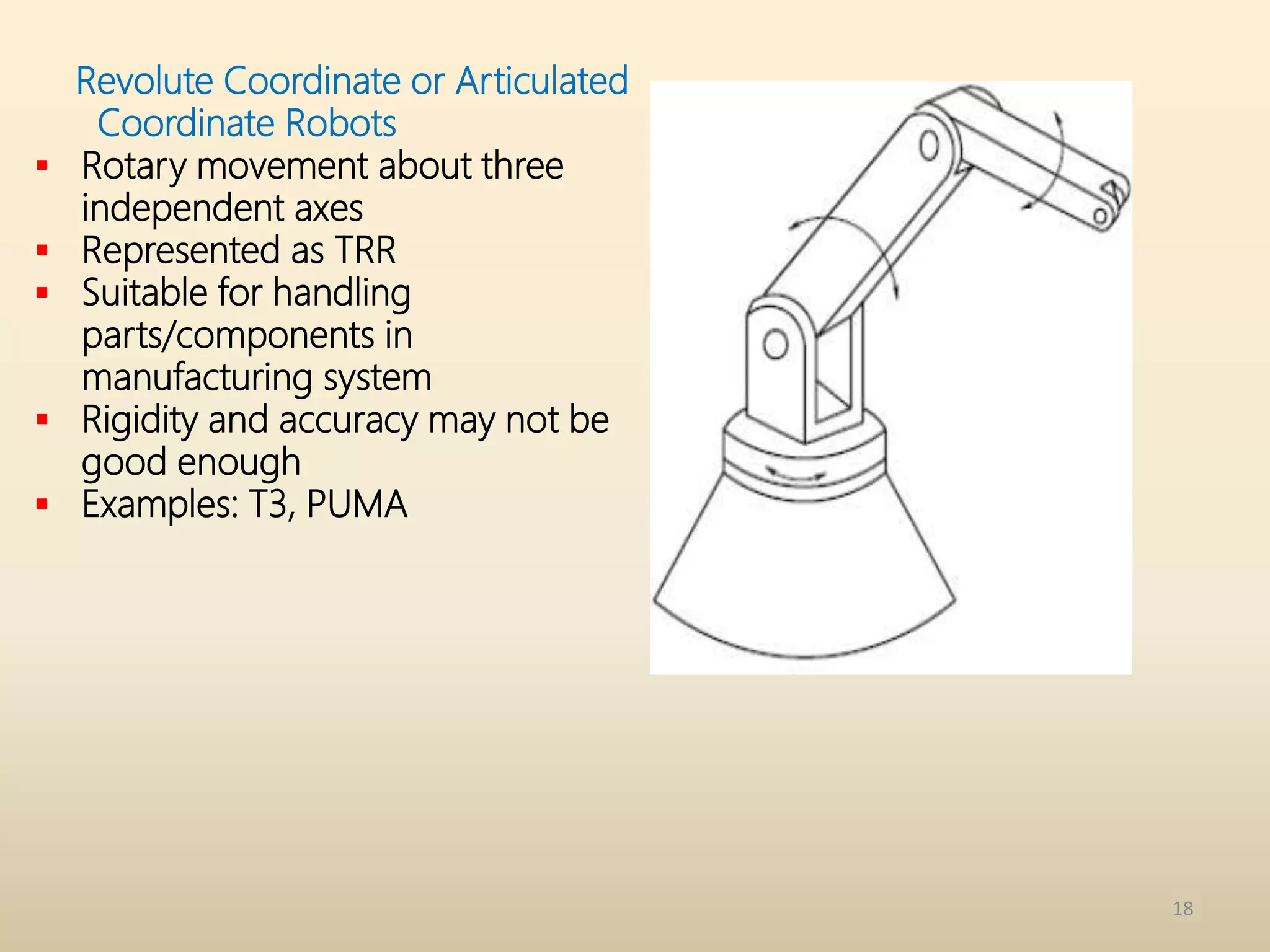

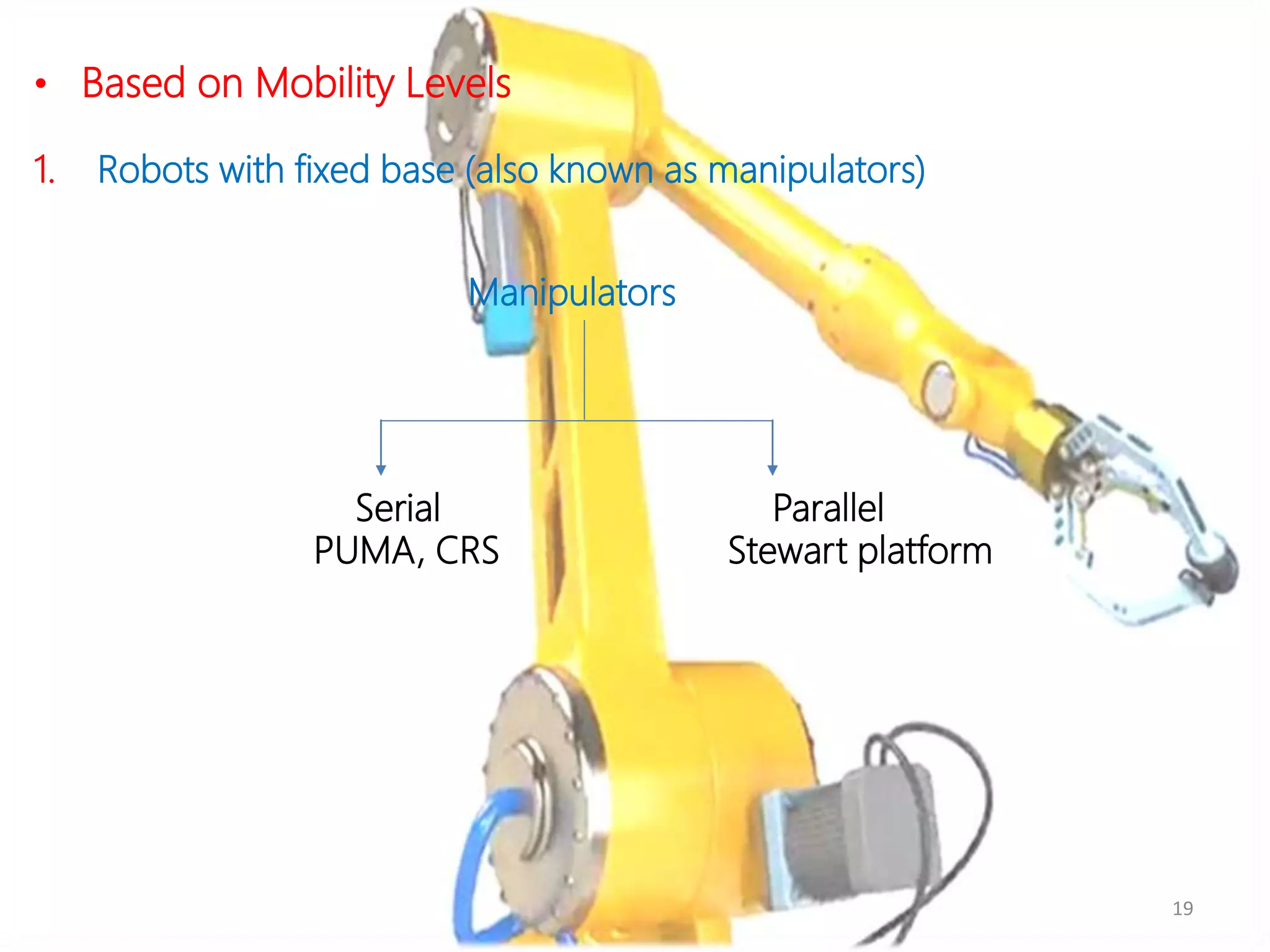

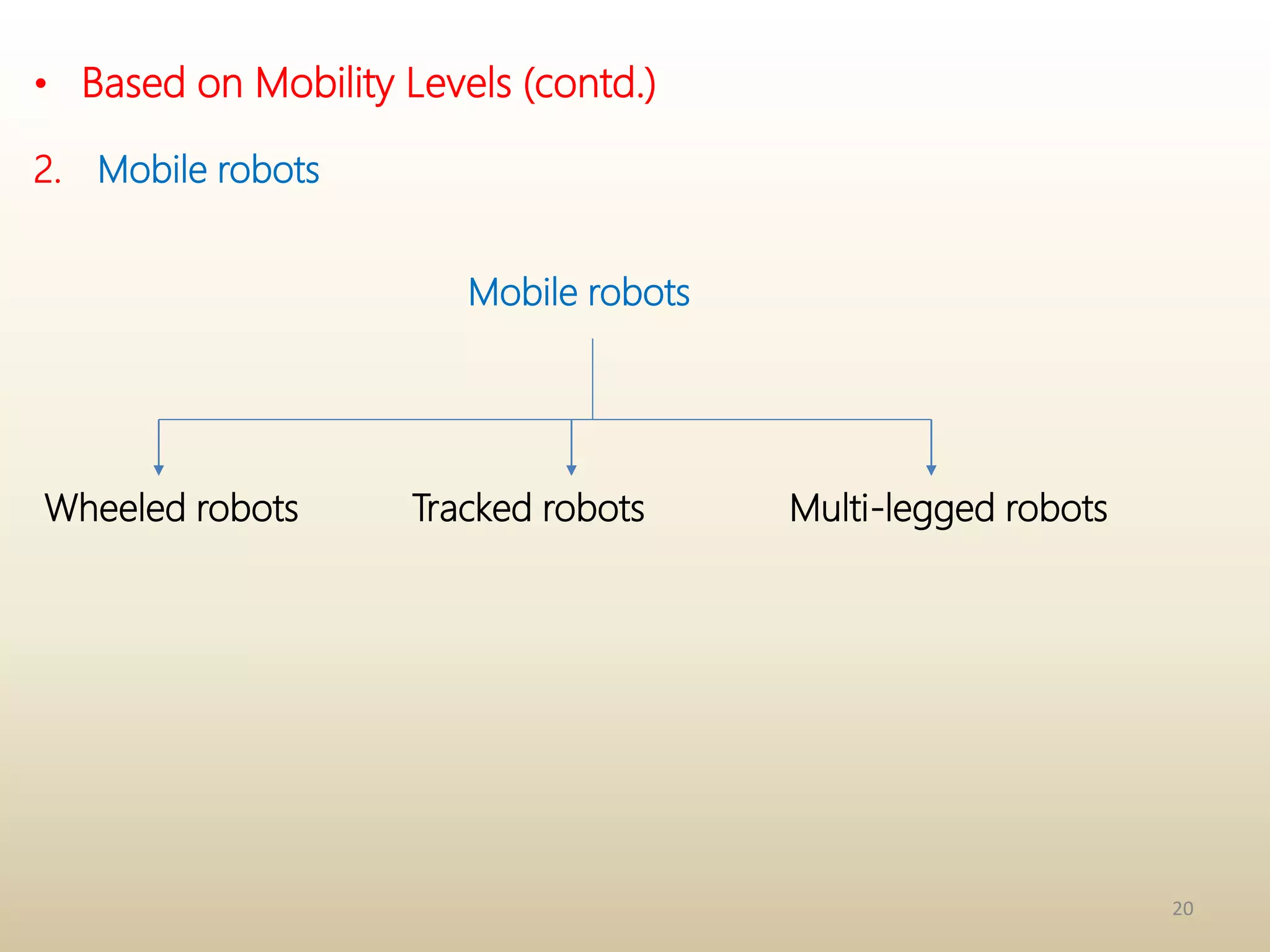

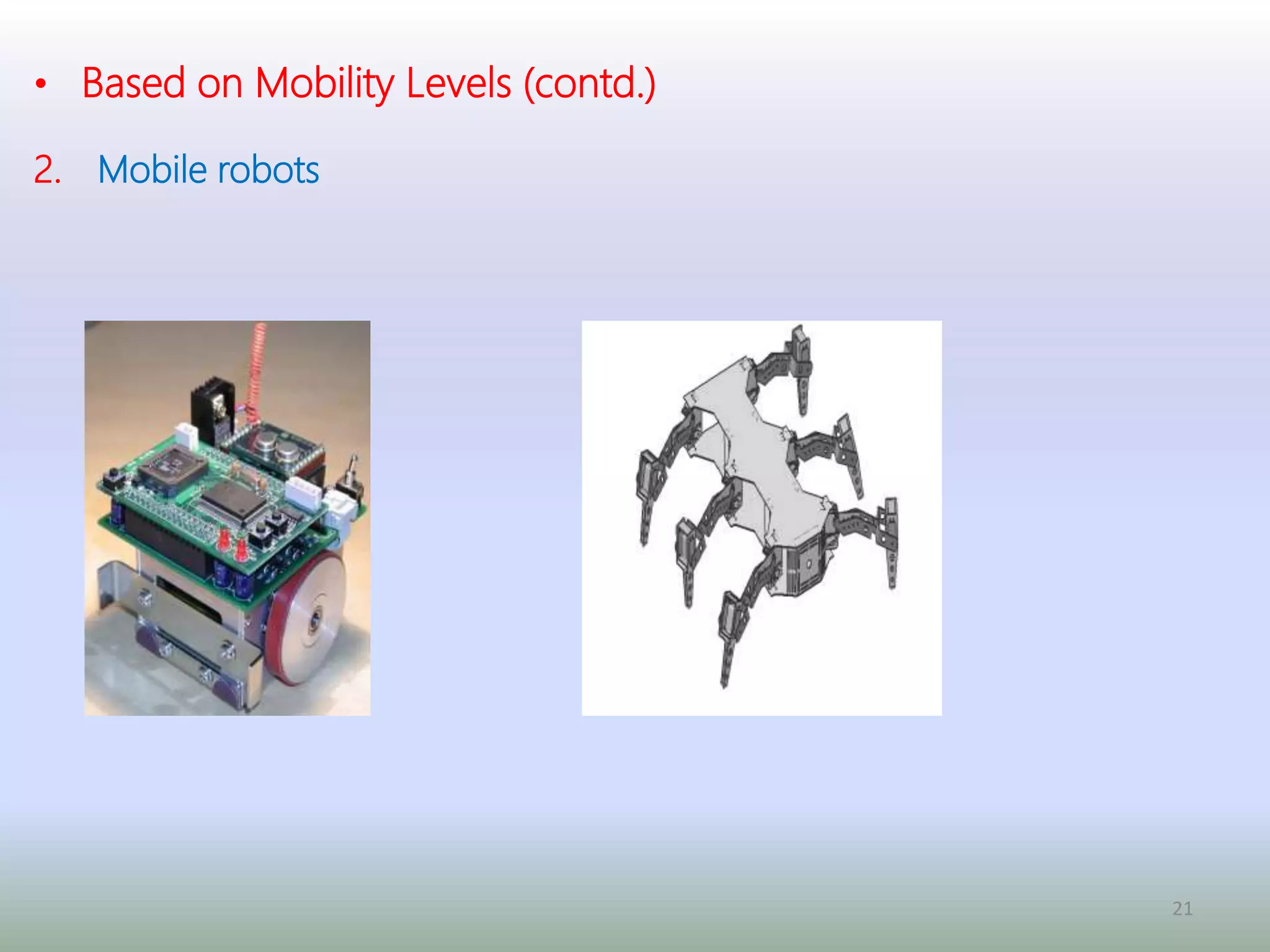

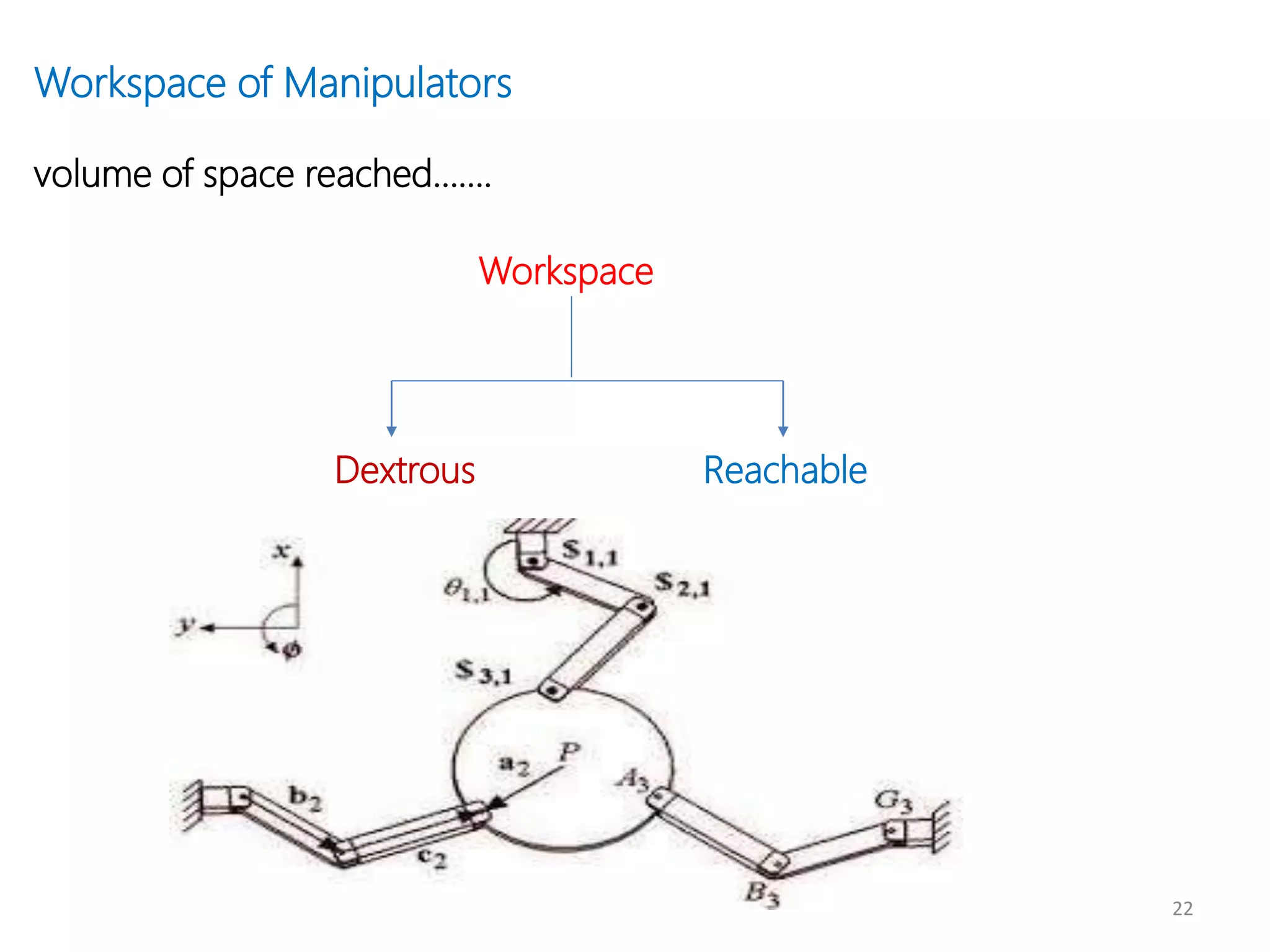

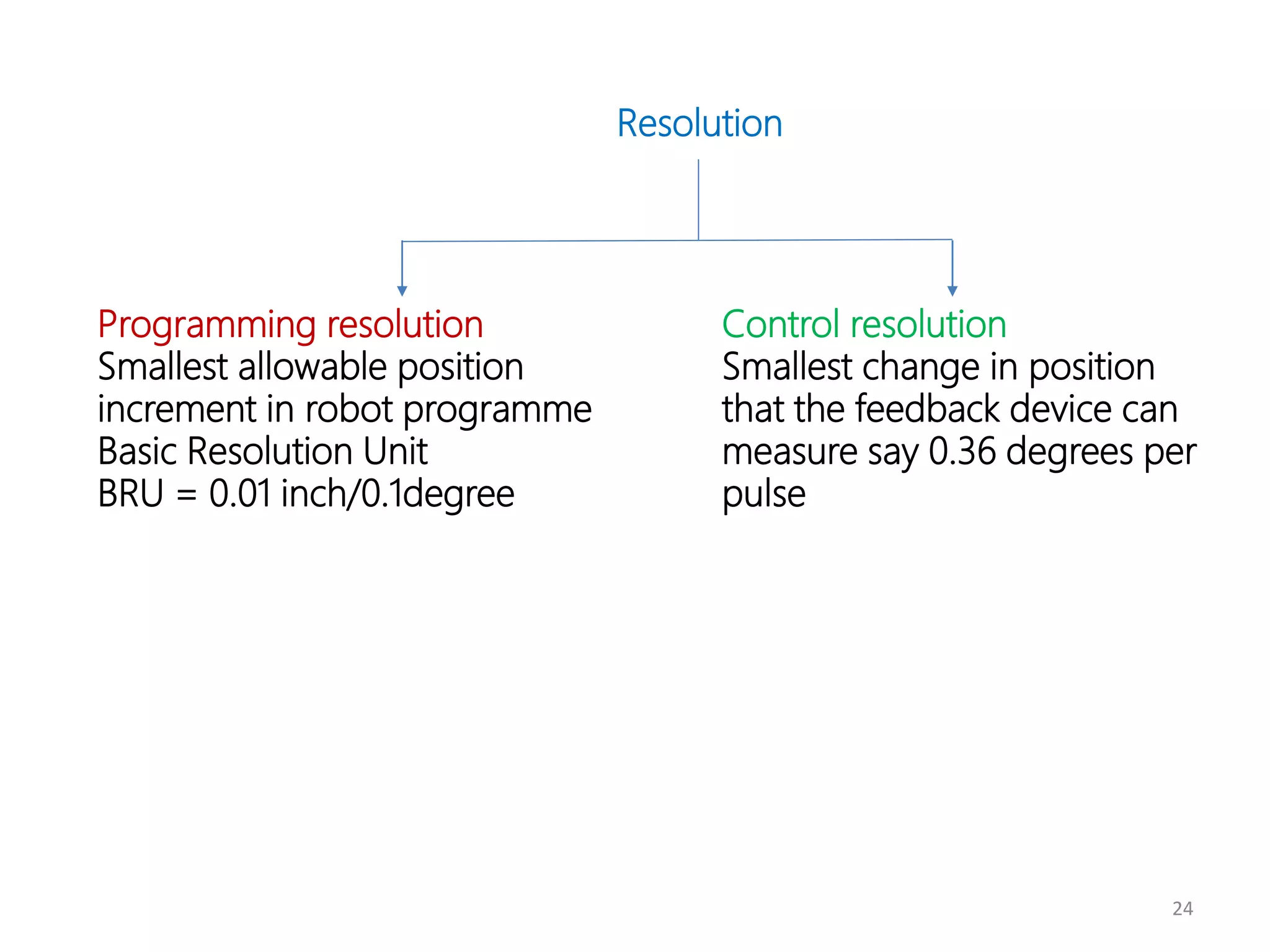

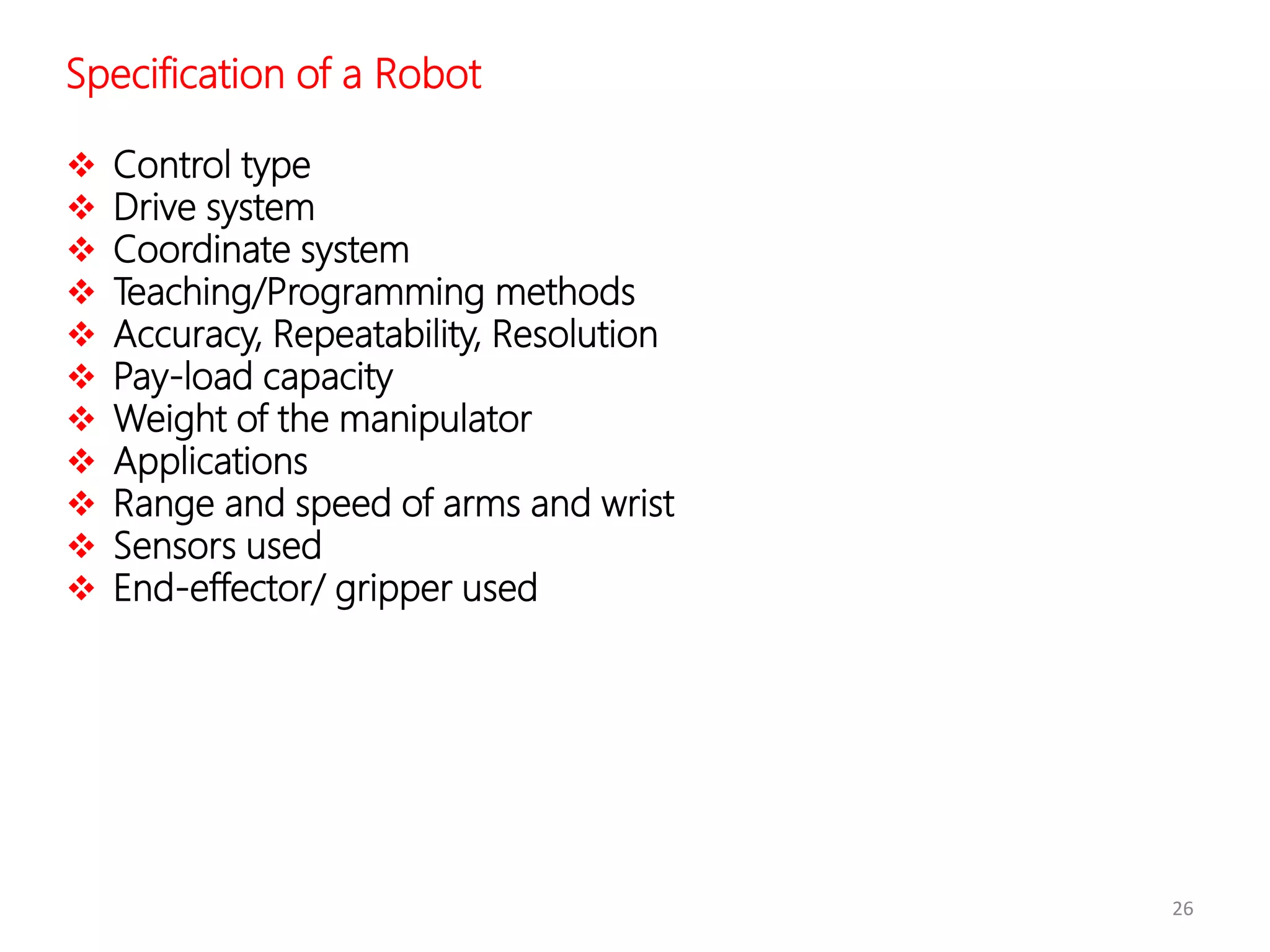

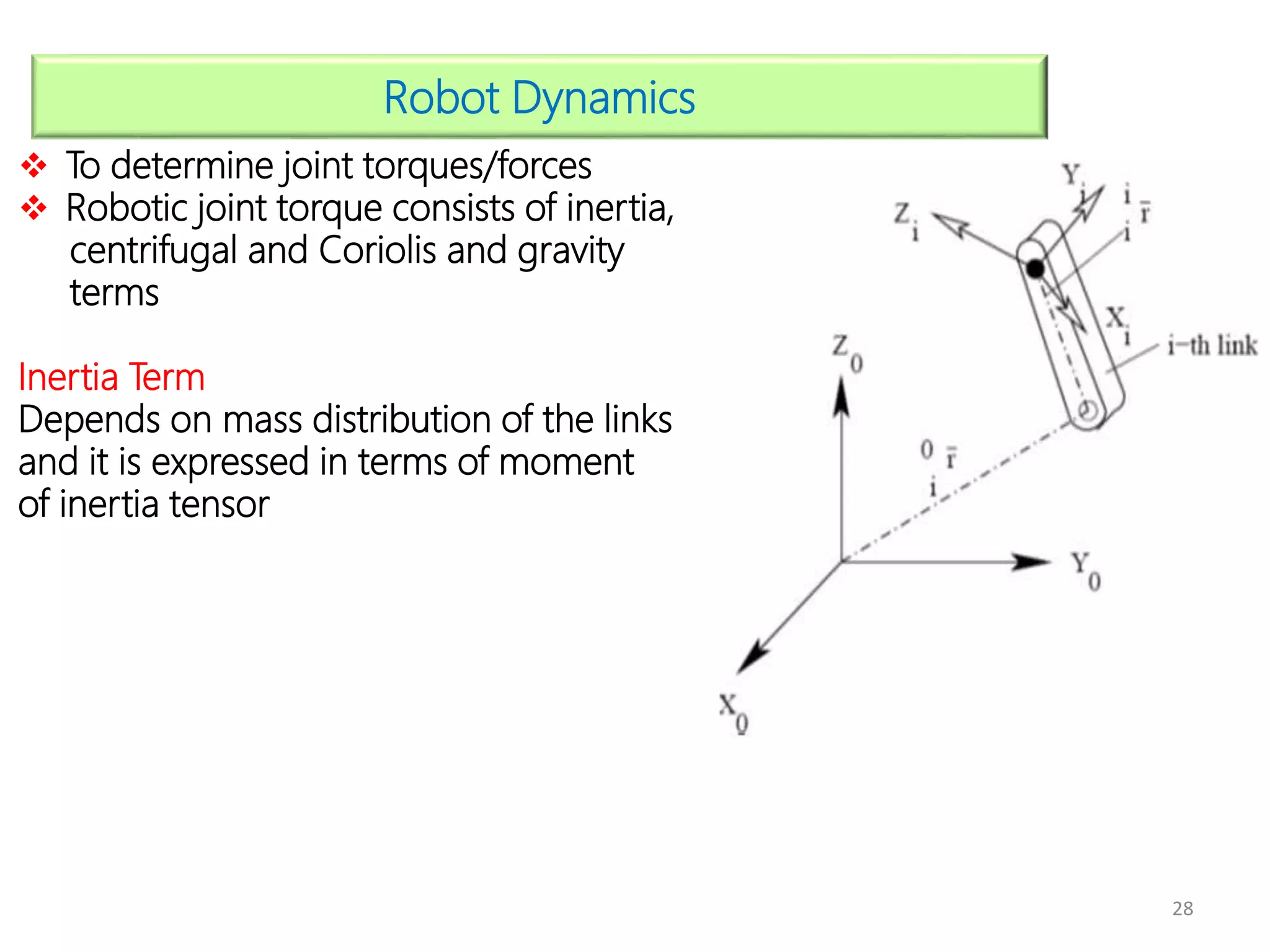

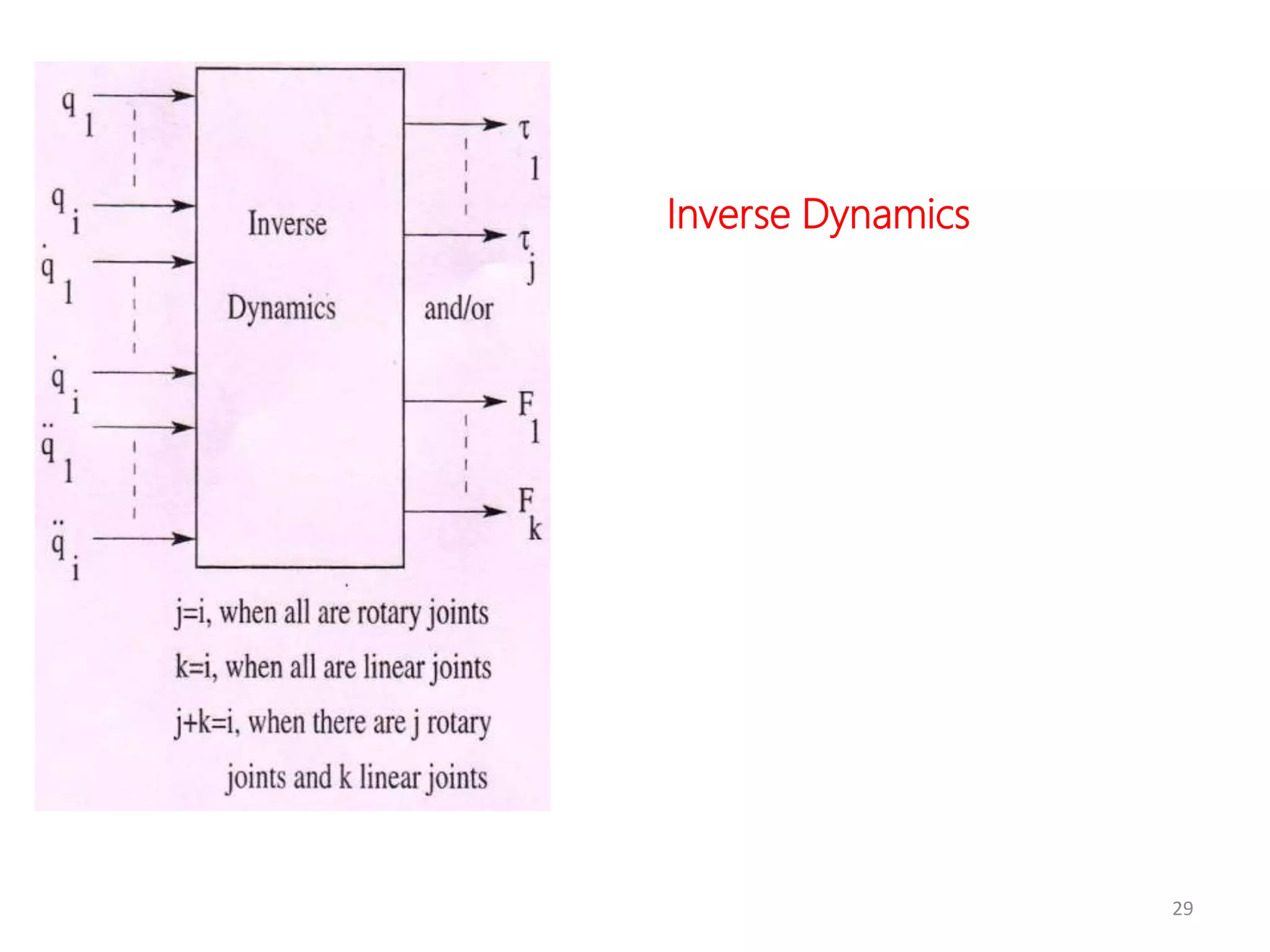

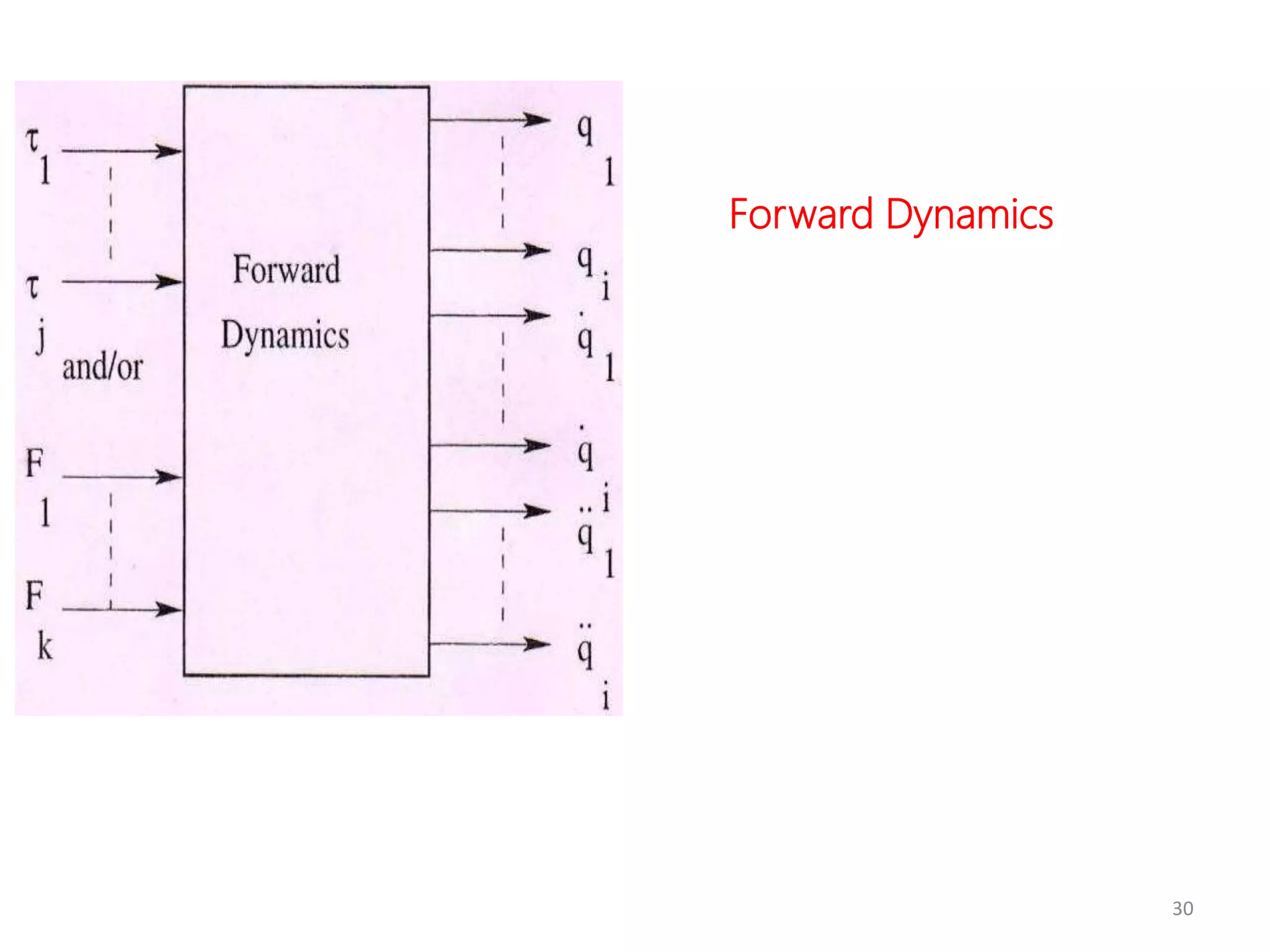

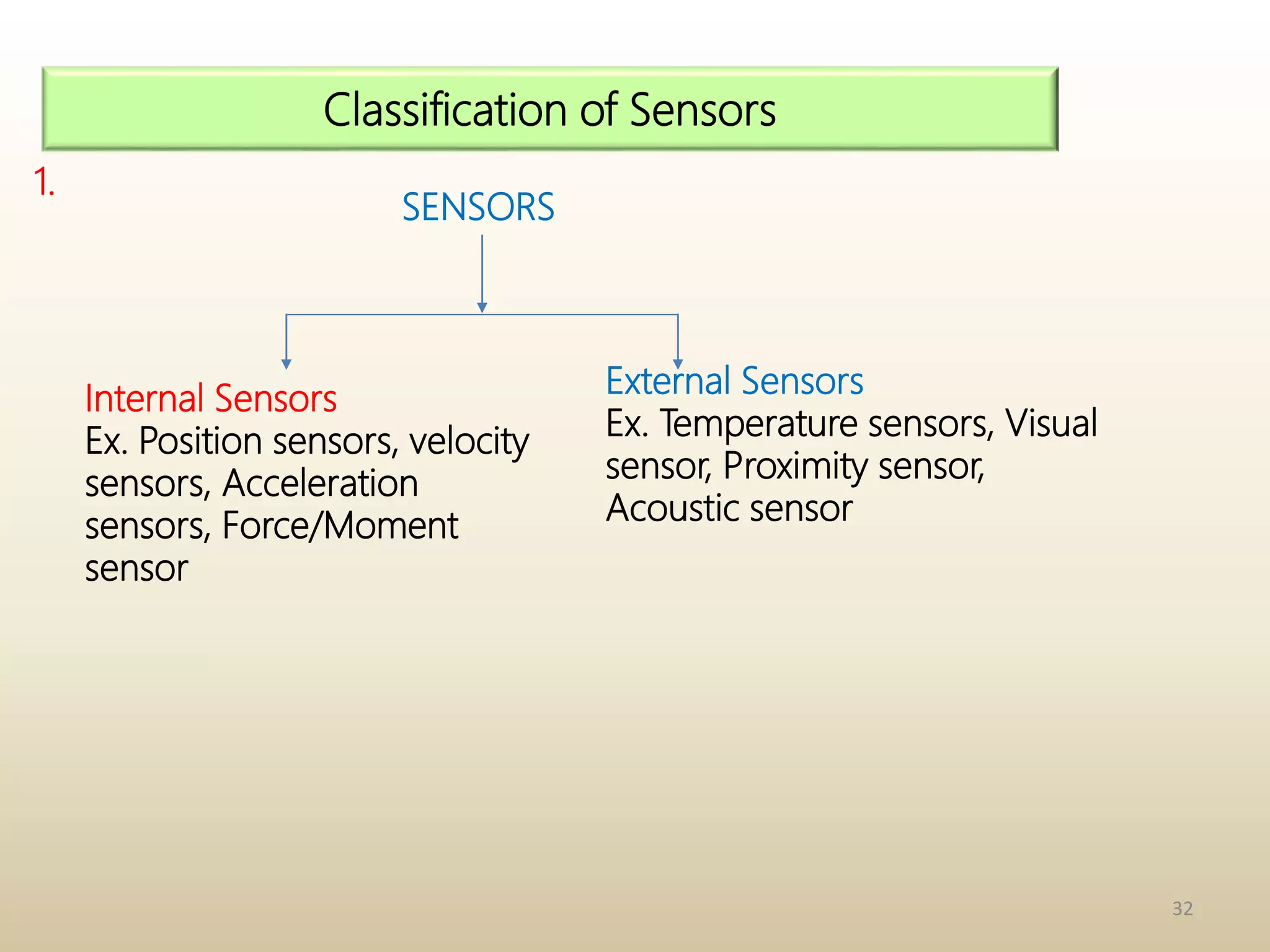

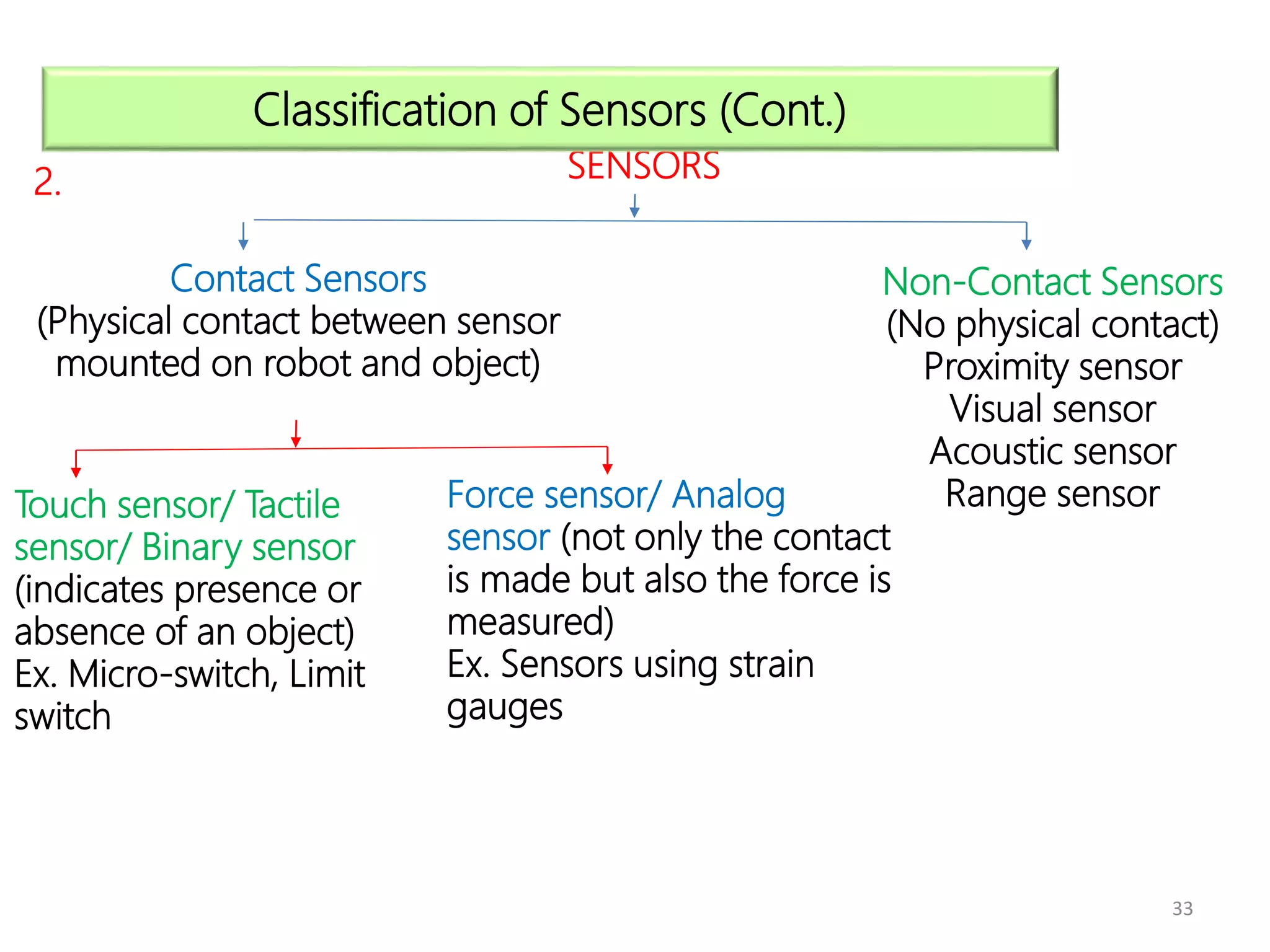

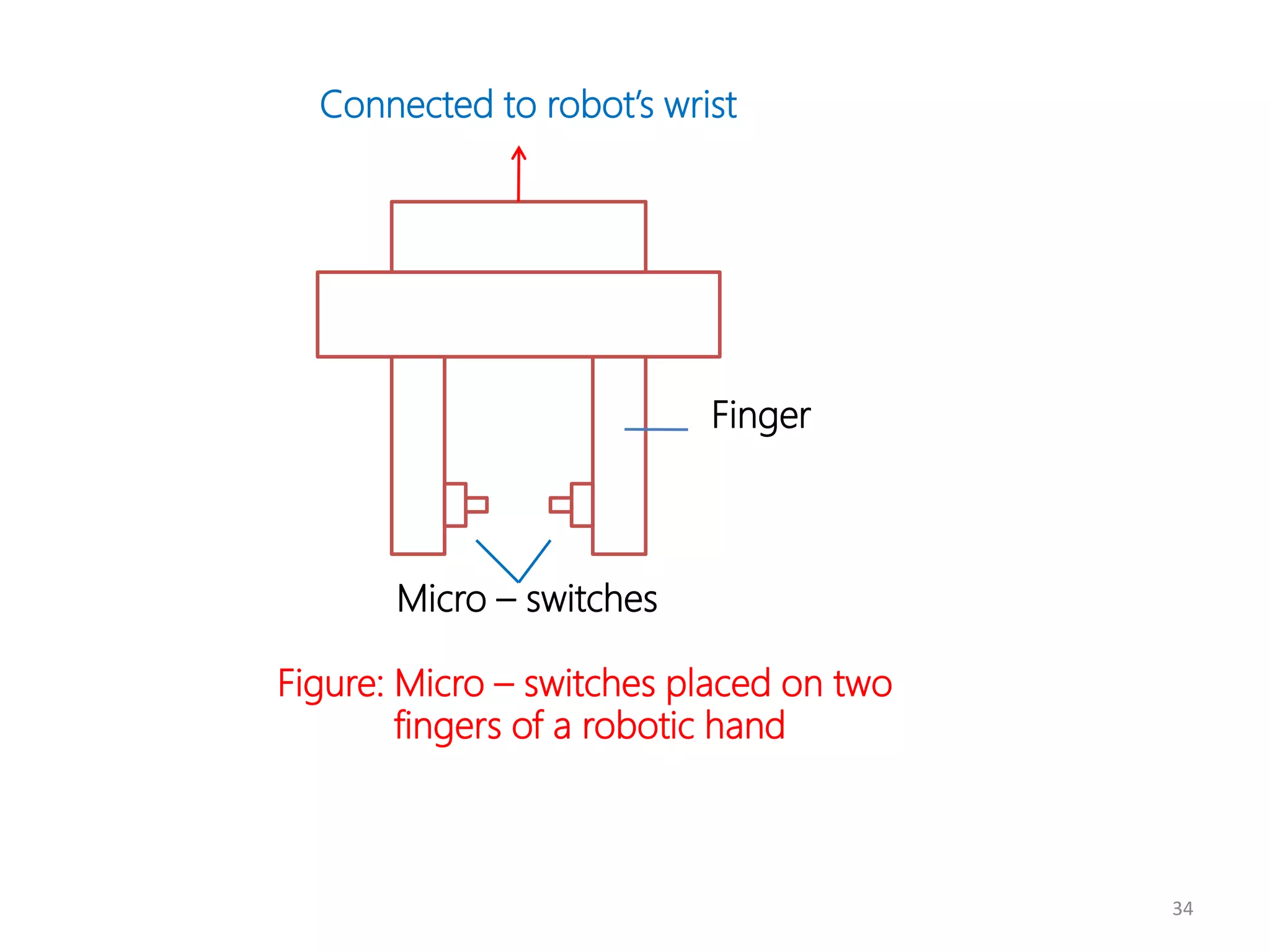

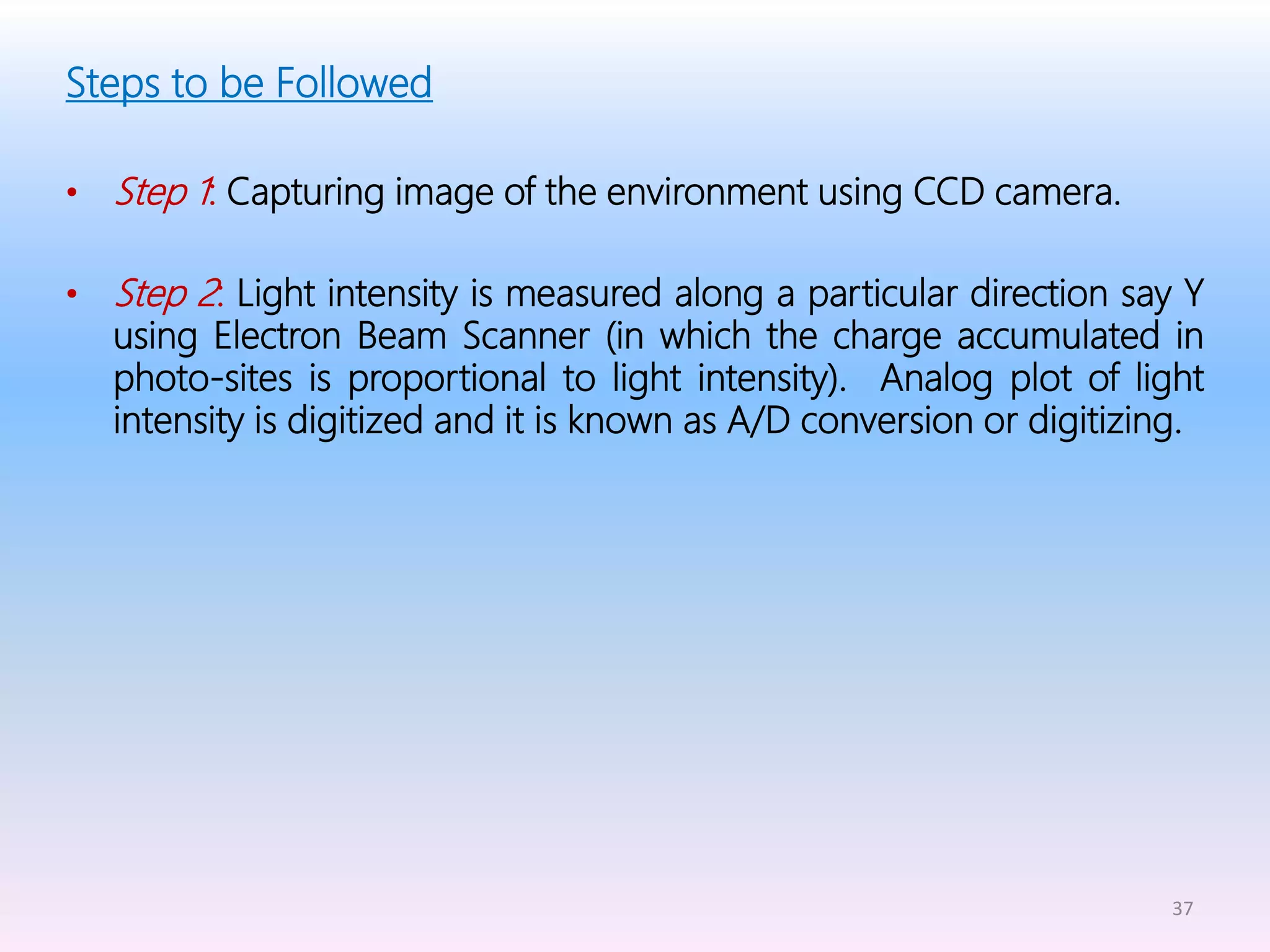

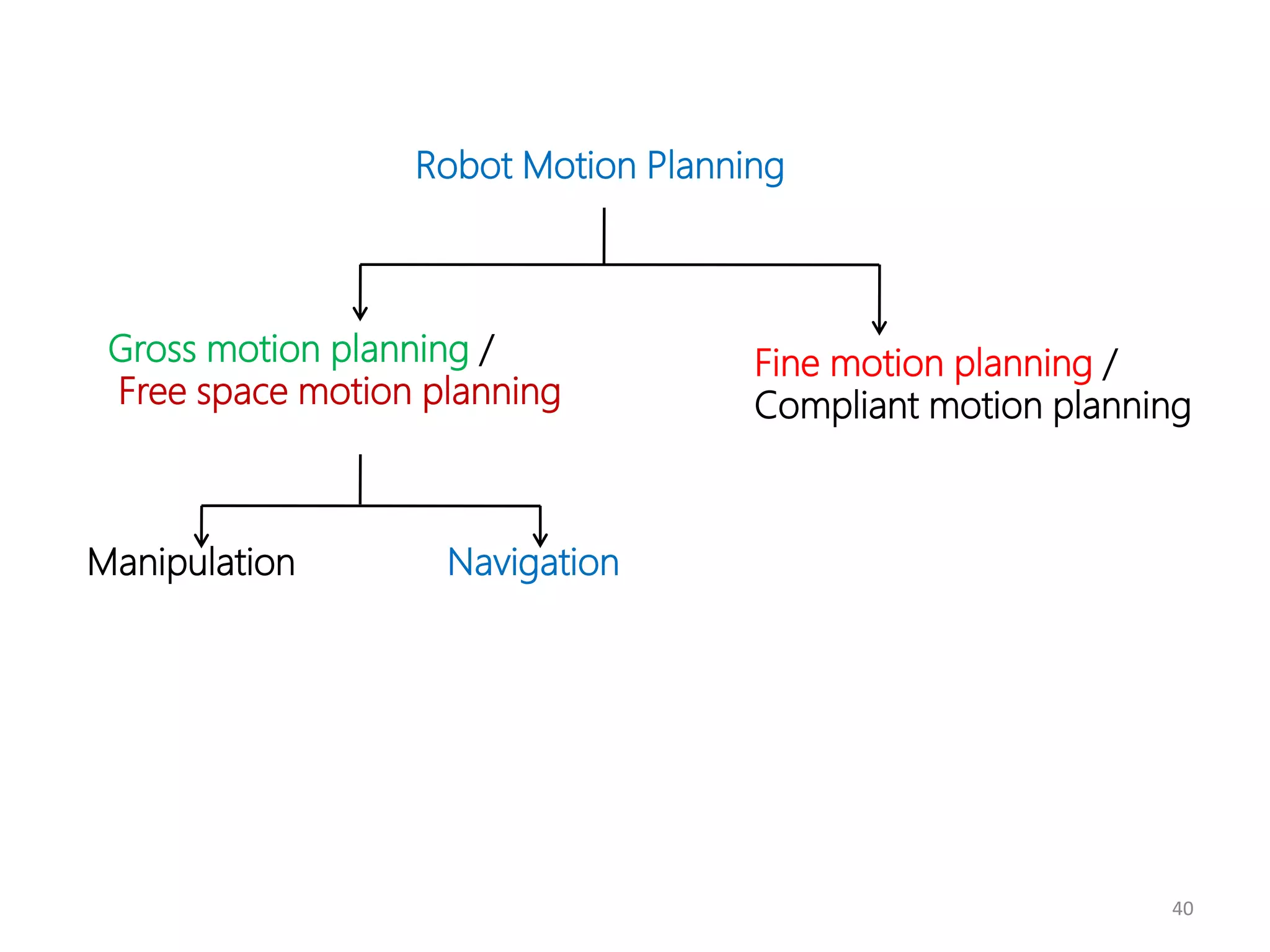

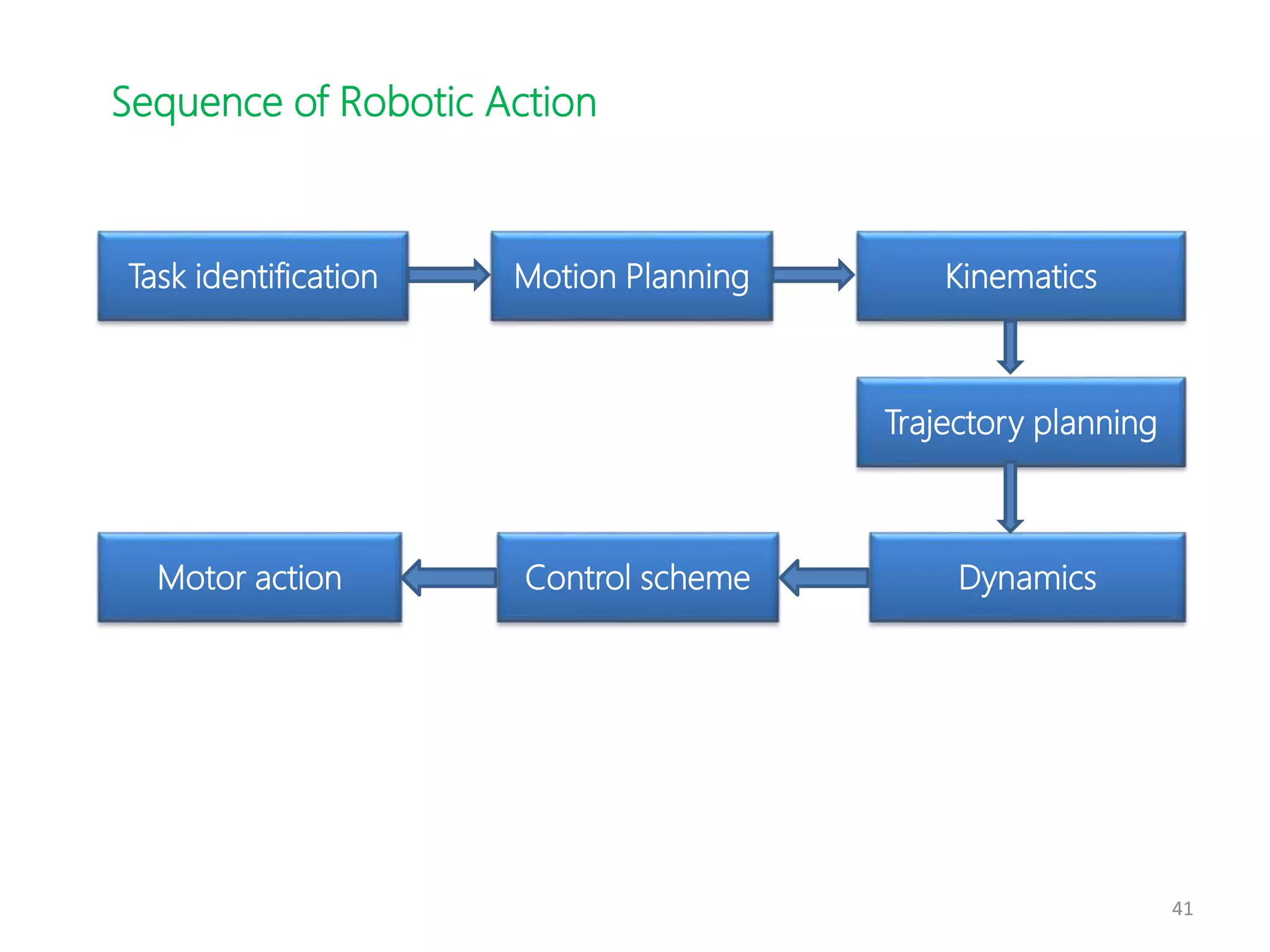

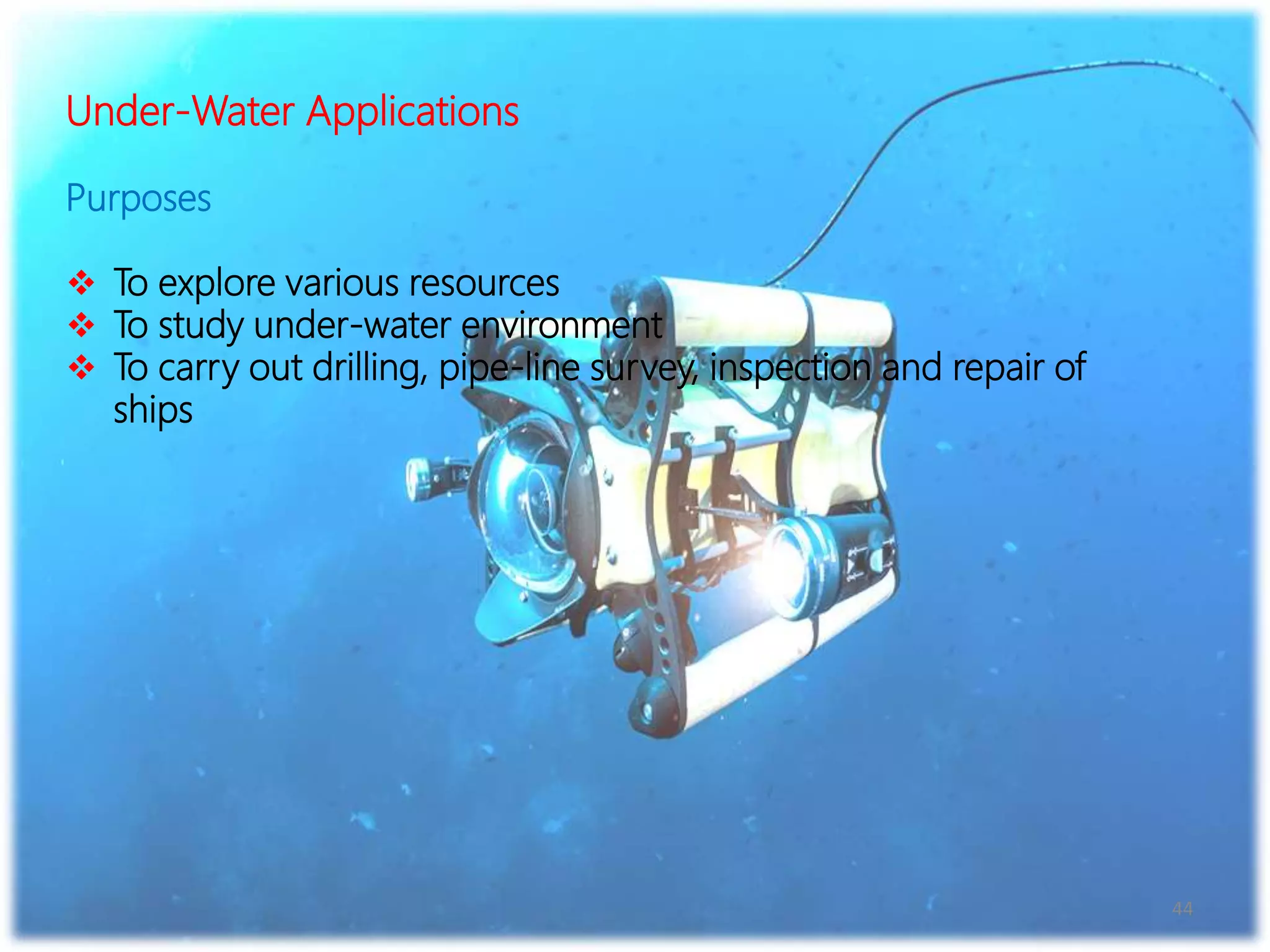

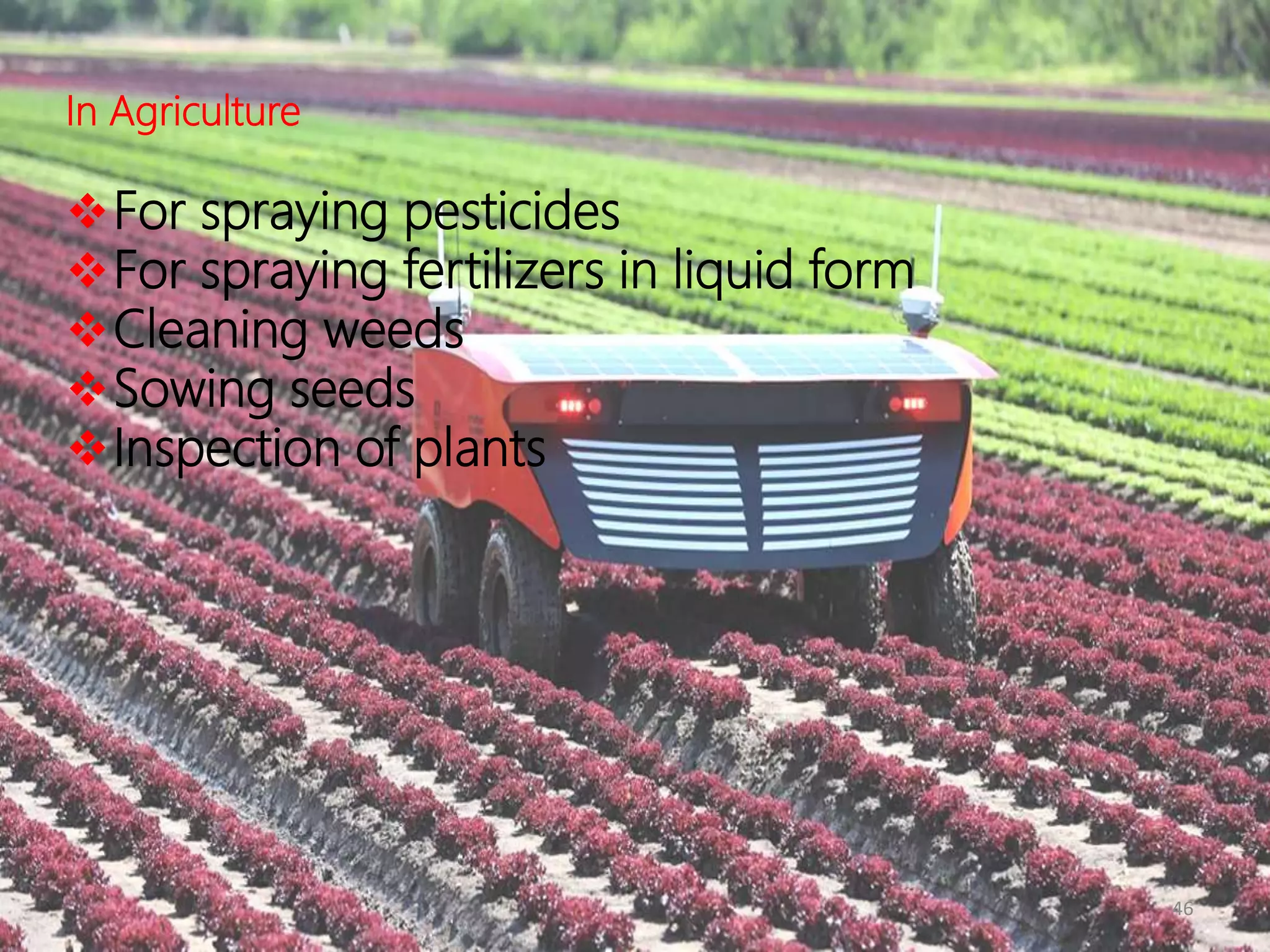

The document provides an overview of robotics, including definitions, history, components, types of robots, and their applications in various fields. Key points include the evolution of robotics, kinematic and dynamic principles, sensor classifications, and motion planning strategies. It also highlights the potential future of intelligent robots and their roles in industries such as manufacturing, agriculture, and space exploration.