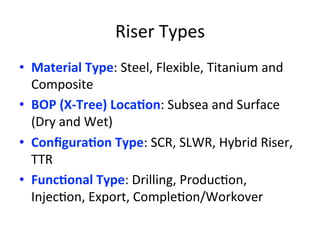

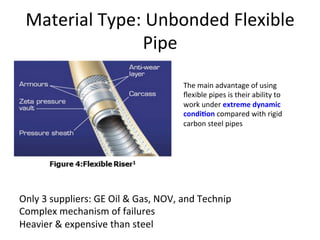

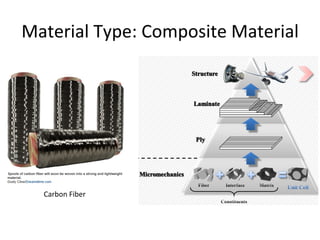

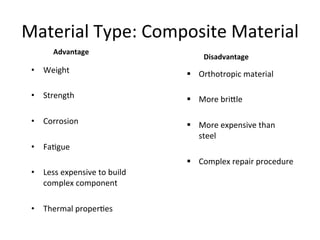

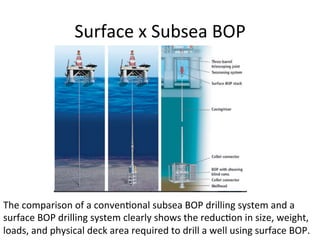

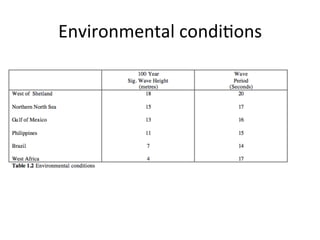

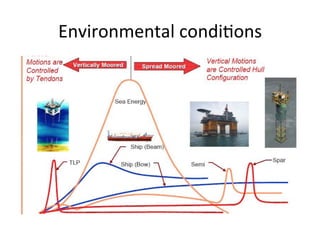

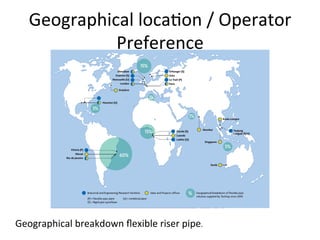

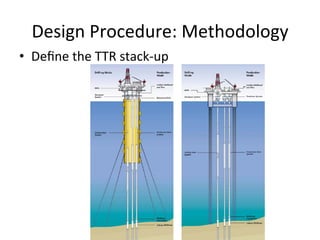

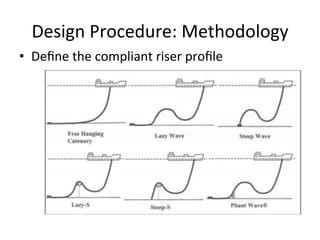

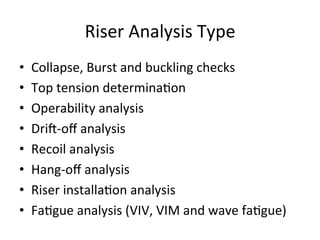

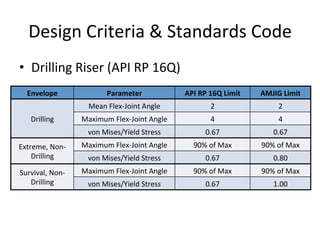

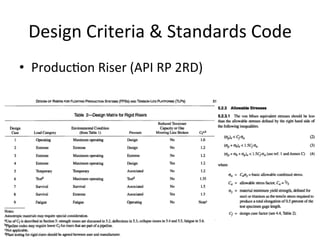

The document provides an overview of deepwater riser design, detailing various riser types, selection factors, and design procedures. It emphasizes the complexity of riser design, highlighting the importance of analyzing multiple factors such as material types, environmental conditions, and operational requirements. The summary concludes that while technical considerations are crucial, non-technical factors can sometimes supersede them in the design process.