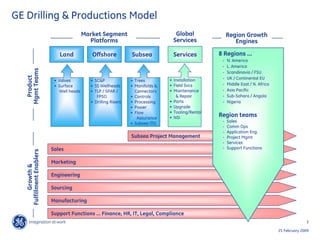

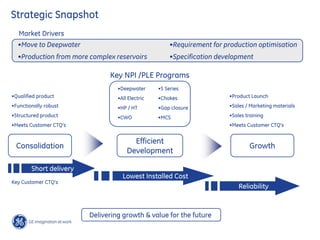

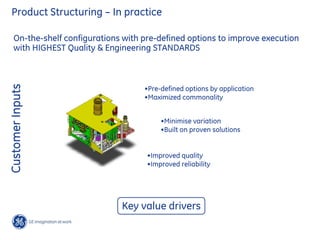

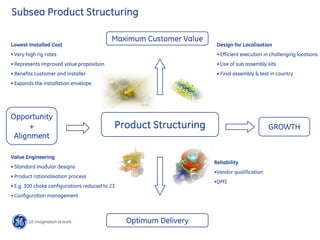

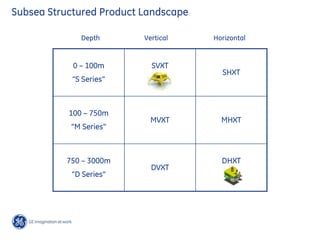

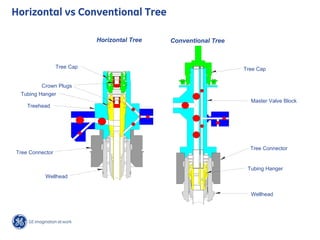

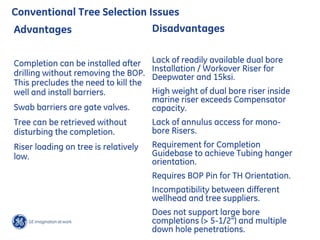

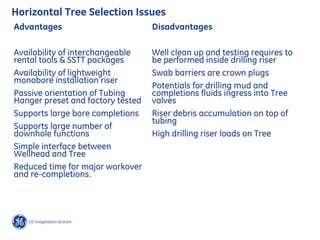

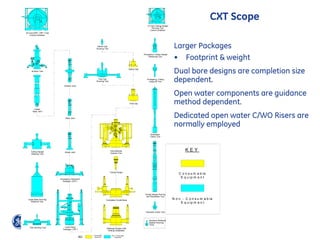

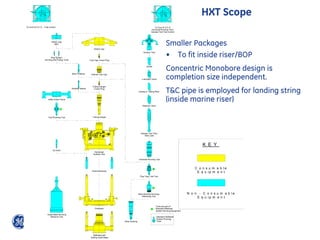

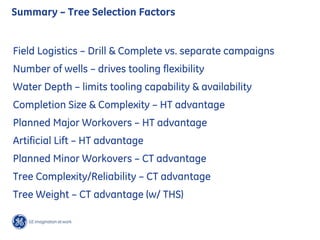

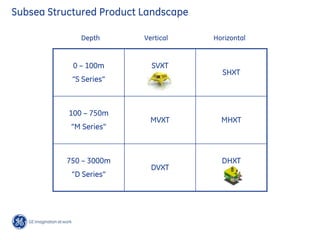

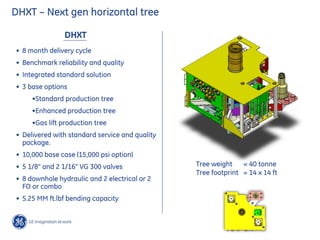

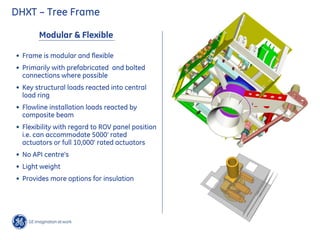

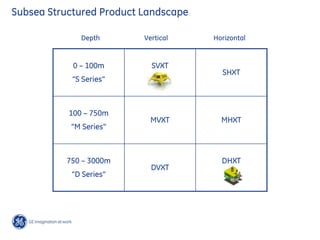

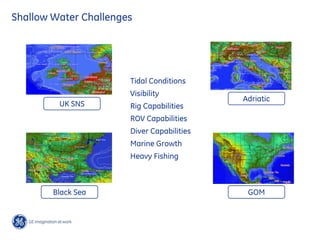

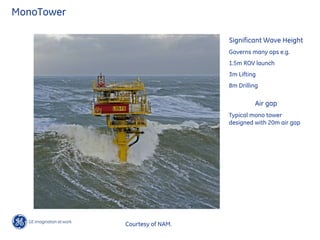

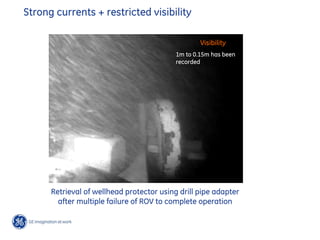

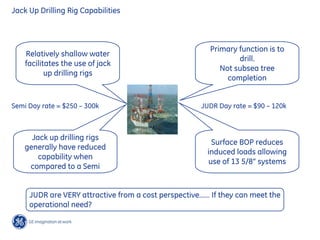

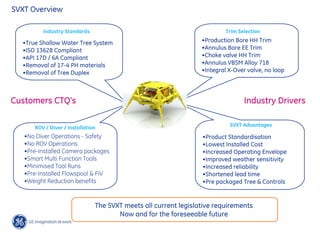

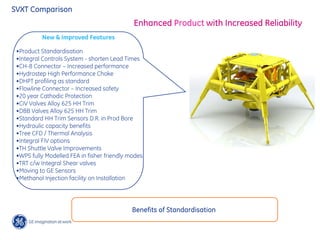

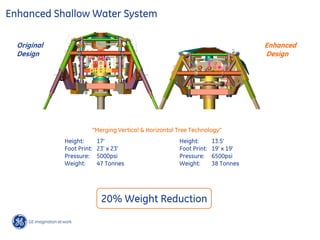

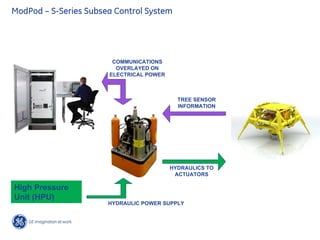

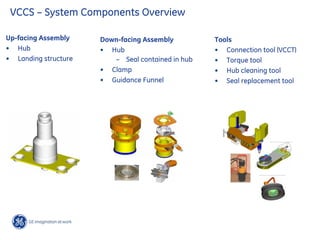

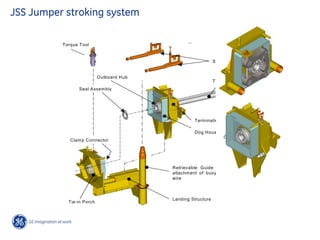

The document discusses GE's subsea product strategy, outlining developments in subsea trees, manifolds, and connection systems for the Western Isles project. It highlights GE's commitment to technology investment, a streamlined product structuring approach, and the strategic importance of deepwater production optimization. The document details different subsea product landscapes and addresses key challenges and advantages encountered in subsea operations.