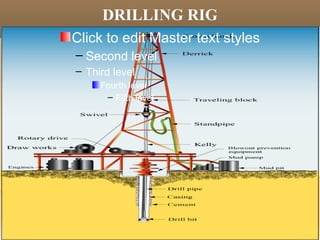

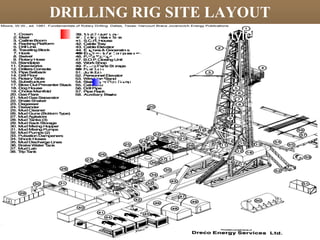

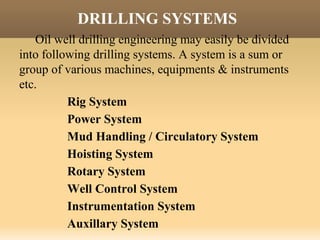

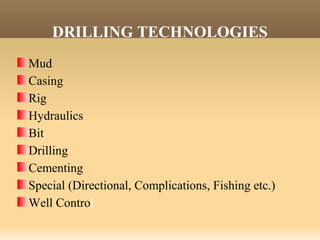

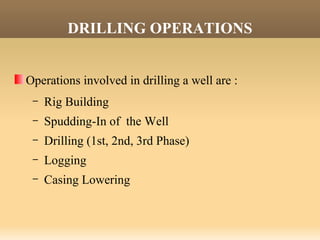

The document provides an overview of drilling in petroleum engineering, defining it as both an art and science for making holes in the earth's crust to extract oil and gas. It outlines various drilling systems, including rig systems and their components, along with the operations involved in drilling a well such as rig building, drilling phases, and well control. Additionally, it explains drilling technology as the standard methods employed for efficient extraction and highlights the importance of engineering and technology in the drilling process.