This document summarizes a student's study of the boiler system at the NTPC Ramagundam thermal power station in India. Key points:

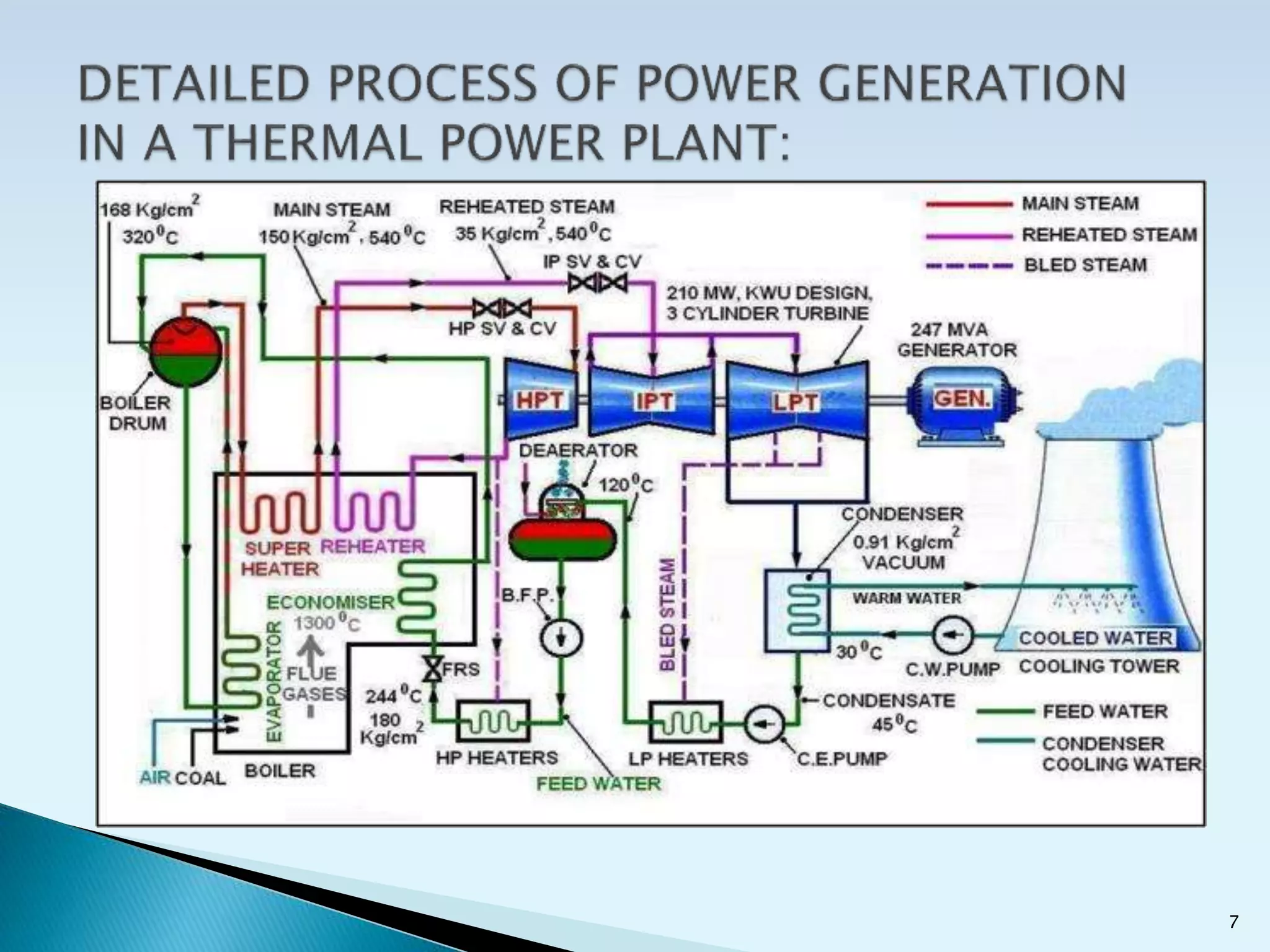

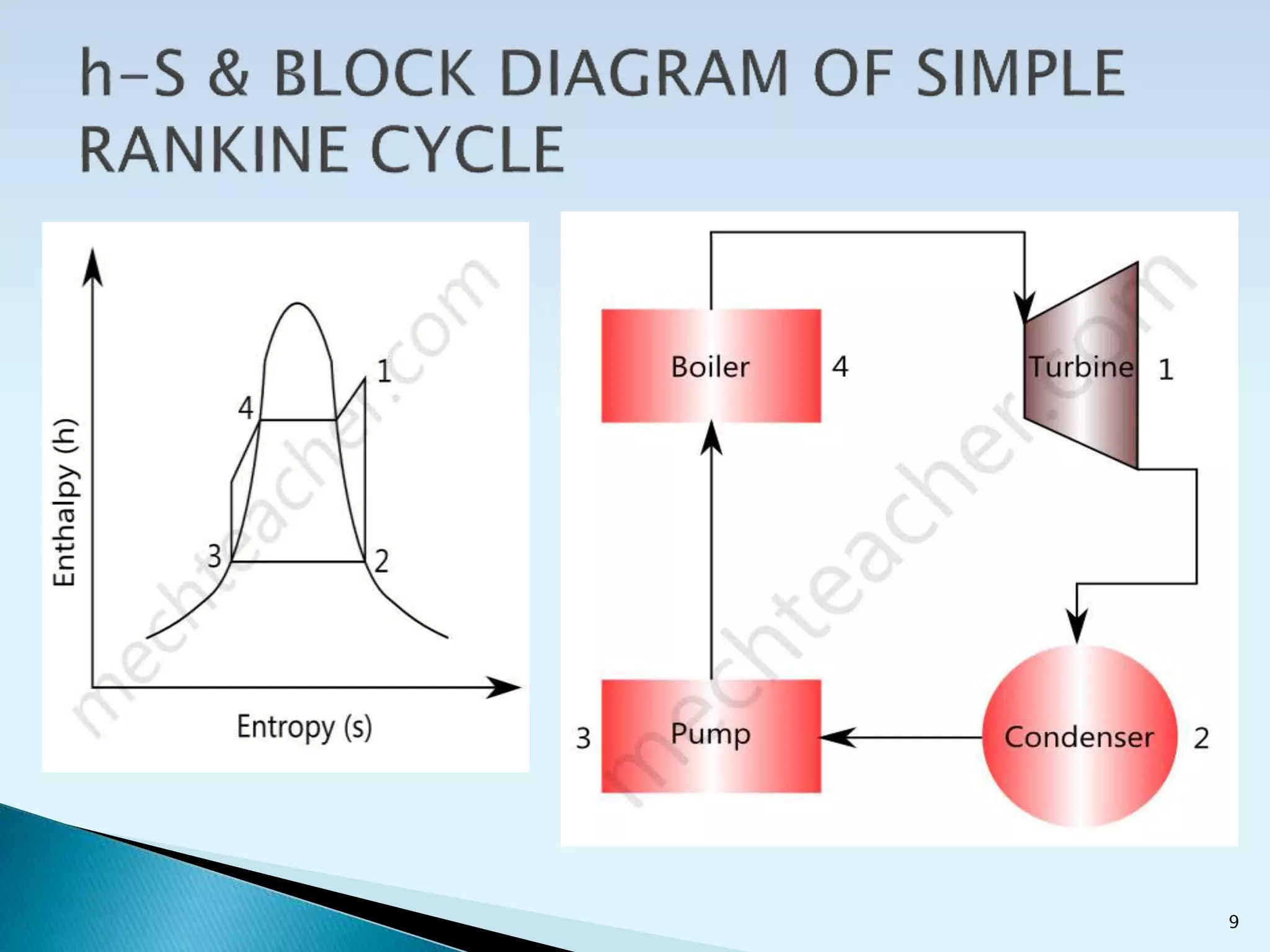

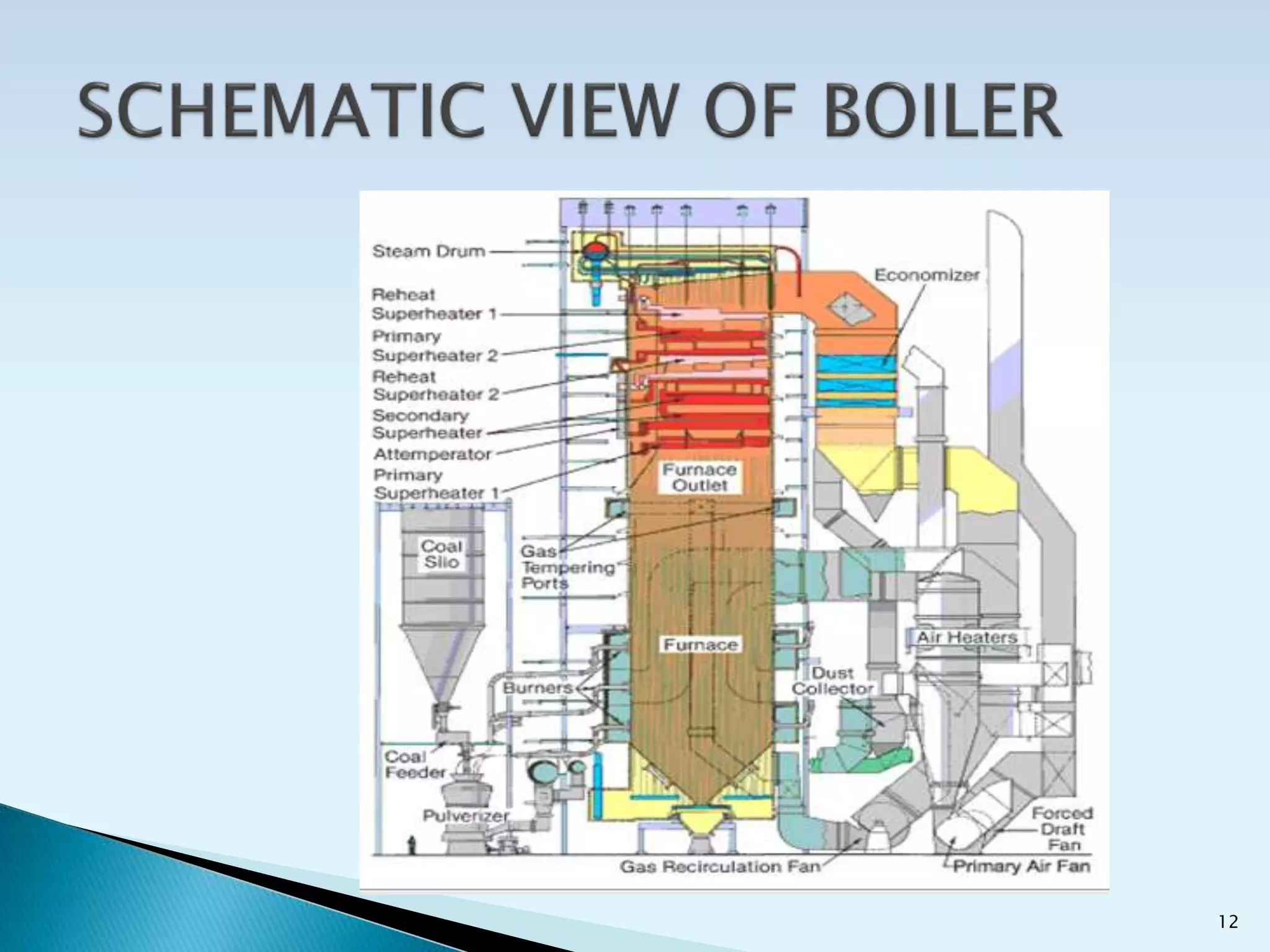

- The study examines how coal is combusted in the boiler to generate high-pressure steam, which is then used to power turbines and generate electricity.

- The NTPC plant uses high-pressure water tube boilers fueled by pulverized coal. It can generate 2600MW of power through 7 generating units.

- Boiler components like water walls, drums, and superheaters are discussed. Steam is generated at high pressures and temperatures before powering turbines.

- Boiler reliability is critical but failures can occur due to issues like poor design