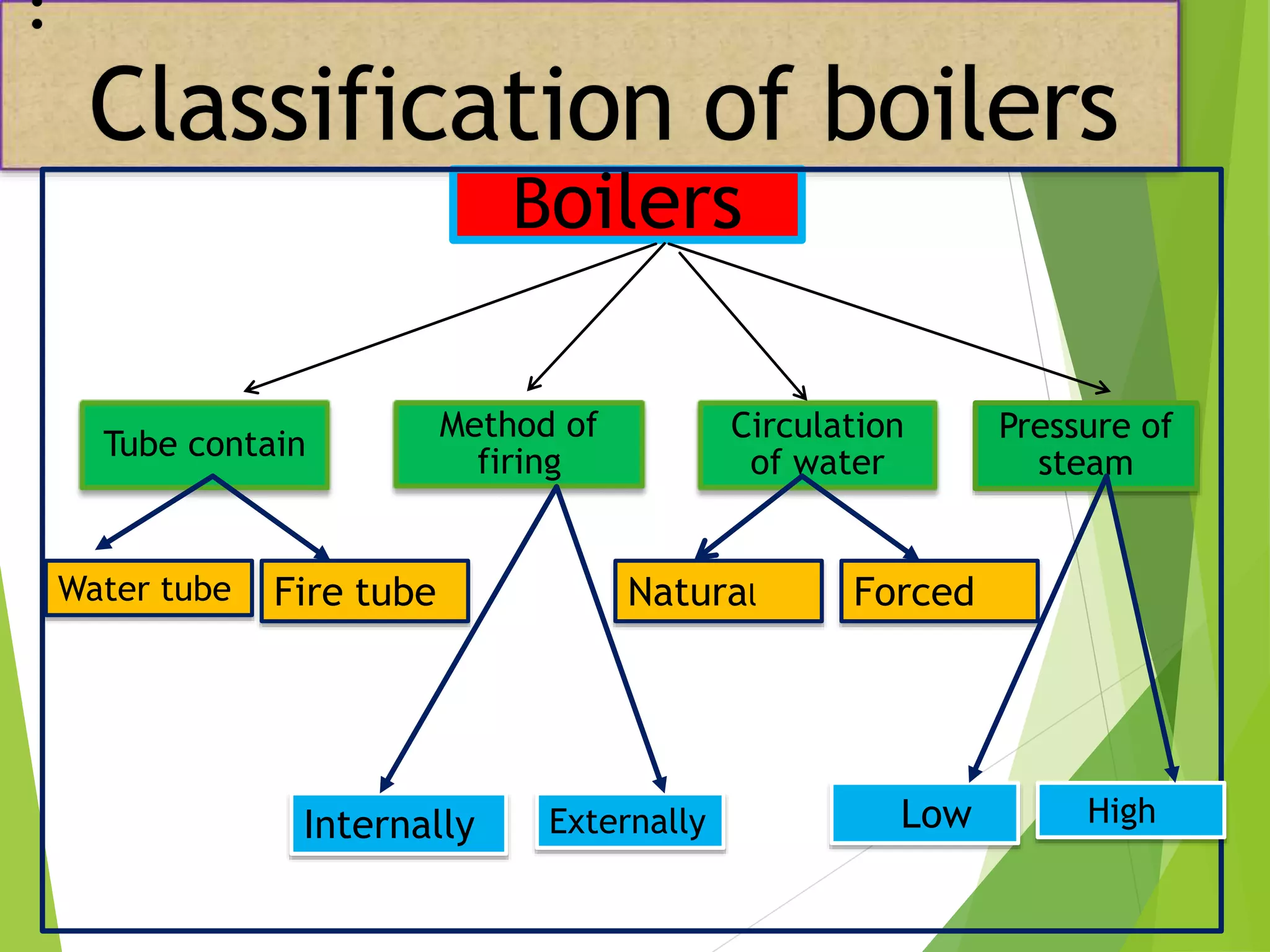

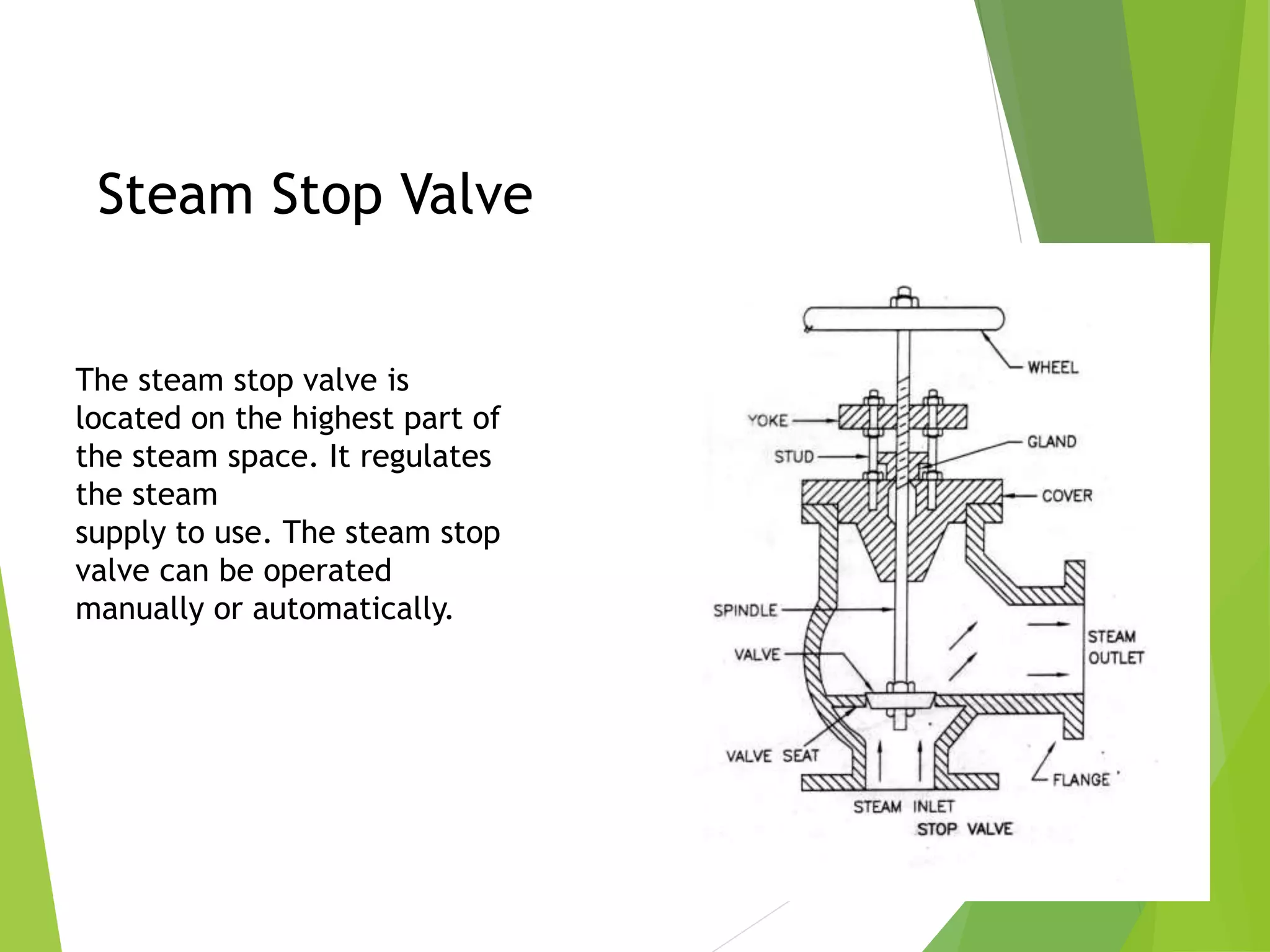

Boilers are closed vessels made of steel that transfer heat from fuel combustion to water to generate steam. They come in two main types: fire tube boilers where hot gases pass through tubes surrounded by water, and water tube boilers where water passes through tubes surrounded by hot gases. Boilers must generate maximum steam, be lightweight, safe, affordable, and easy to access for maintenance. Steam is used for power generation, heating, and in chemical processes. Boiler efficiency is important and various accessories like economizers and superheaters are used to improve it. Understanding boilers is essential for the chemical industry as most used are high efficiency, safe water tube designs.