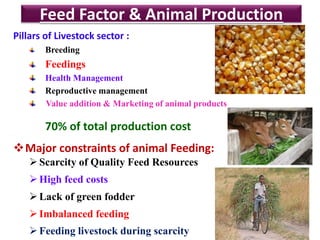

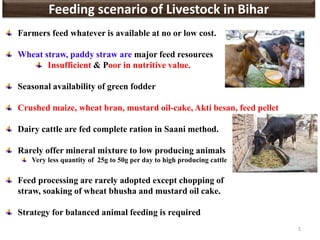

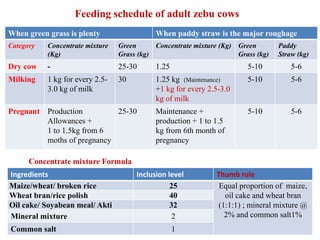

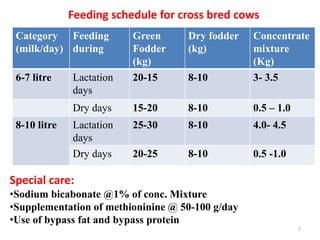

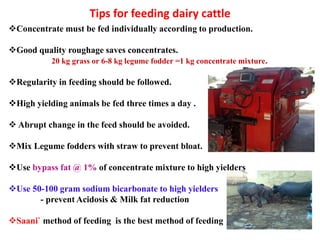

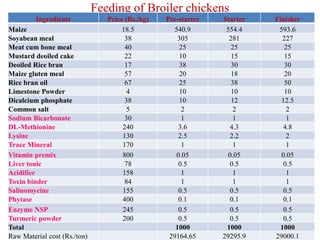

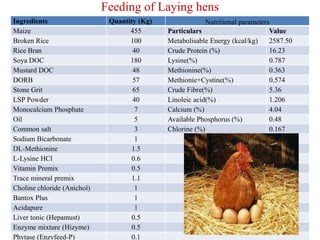

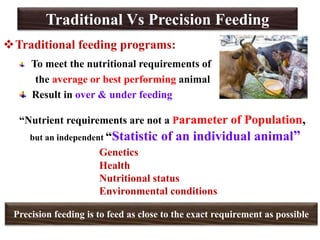

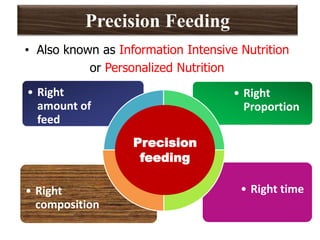

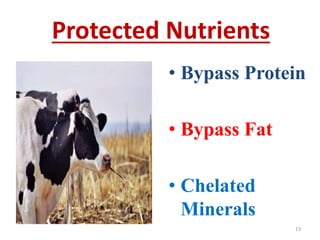

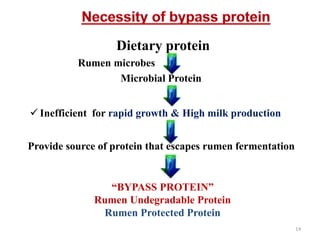

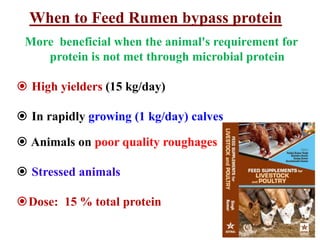

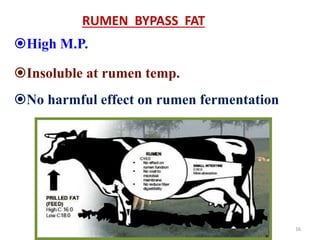

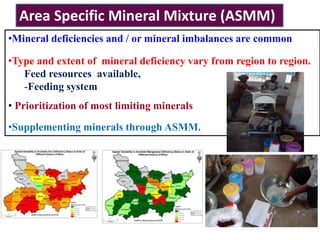

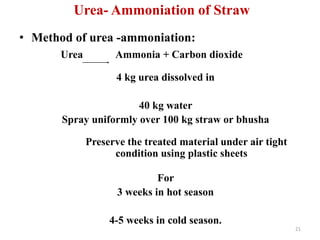

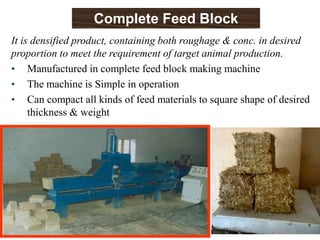

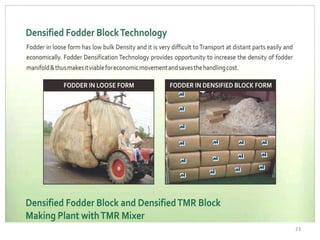

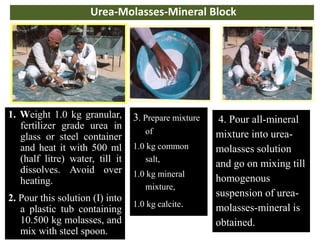

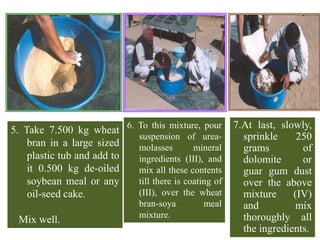

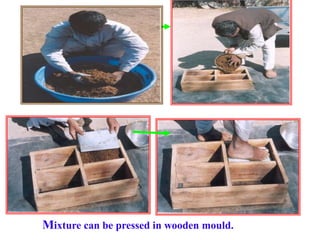

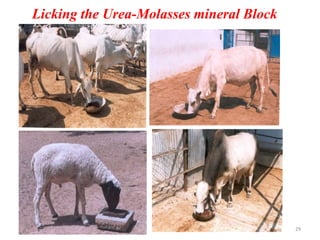

The document discusses feeding practices for livestock in India. It notes that feeding accounts for 70% of total livestock production costs. Major constraints to feeding include scarcity of quality feed resources and imbalanced feeding. The document recommends strategies like precision feeding, using protected nutrients like bypass protein and fat, area-specific mineral mixtures, feed processing techniques like silage and complete feed blocks. It provides feeding schedules and formulations for dairy cattle, poultry and laying hens. The document emphasizes adopting the right feeding strategies tailored to individual animal needs for economical and sustainable livestock production.