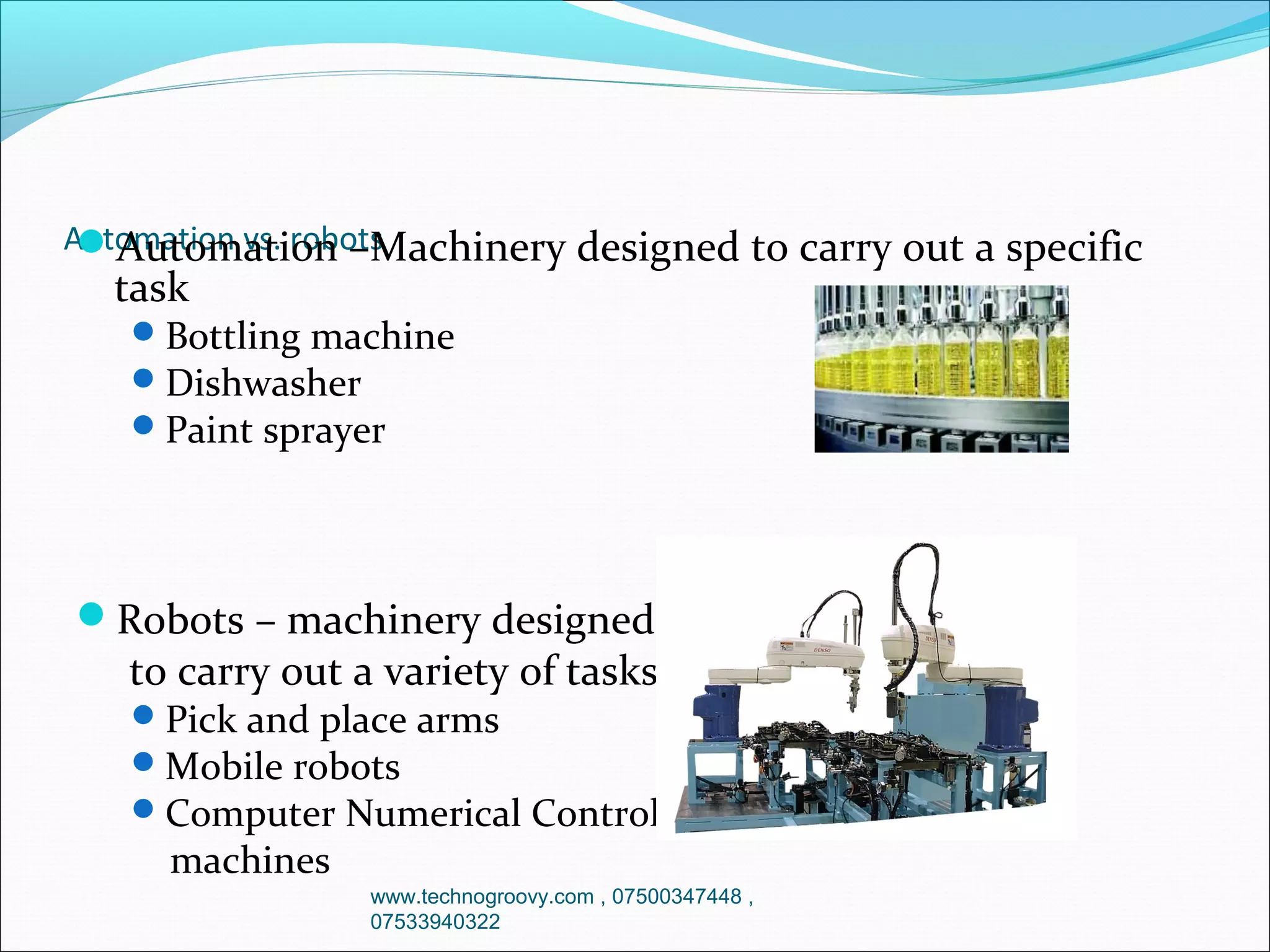

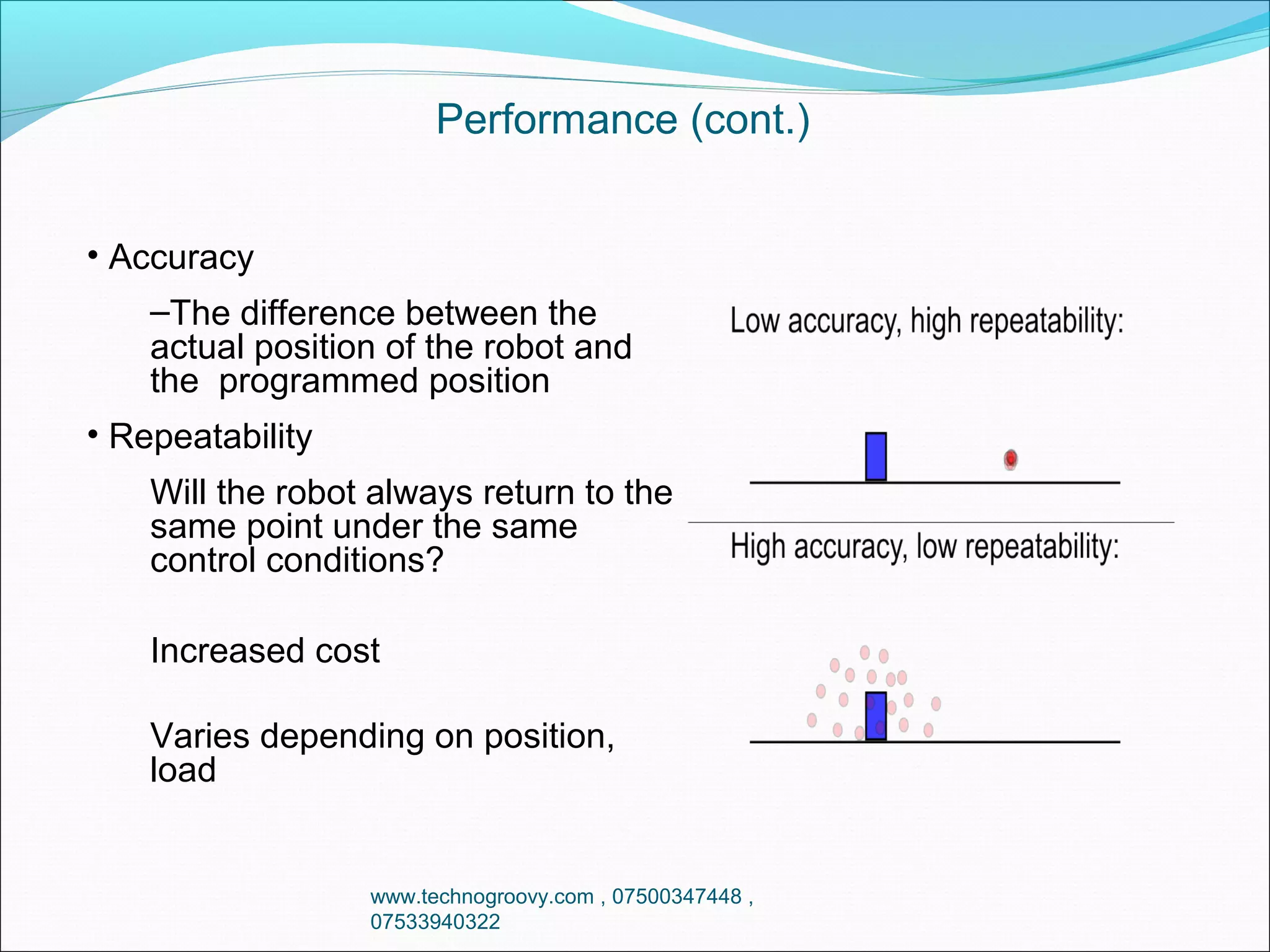

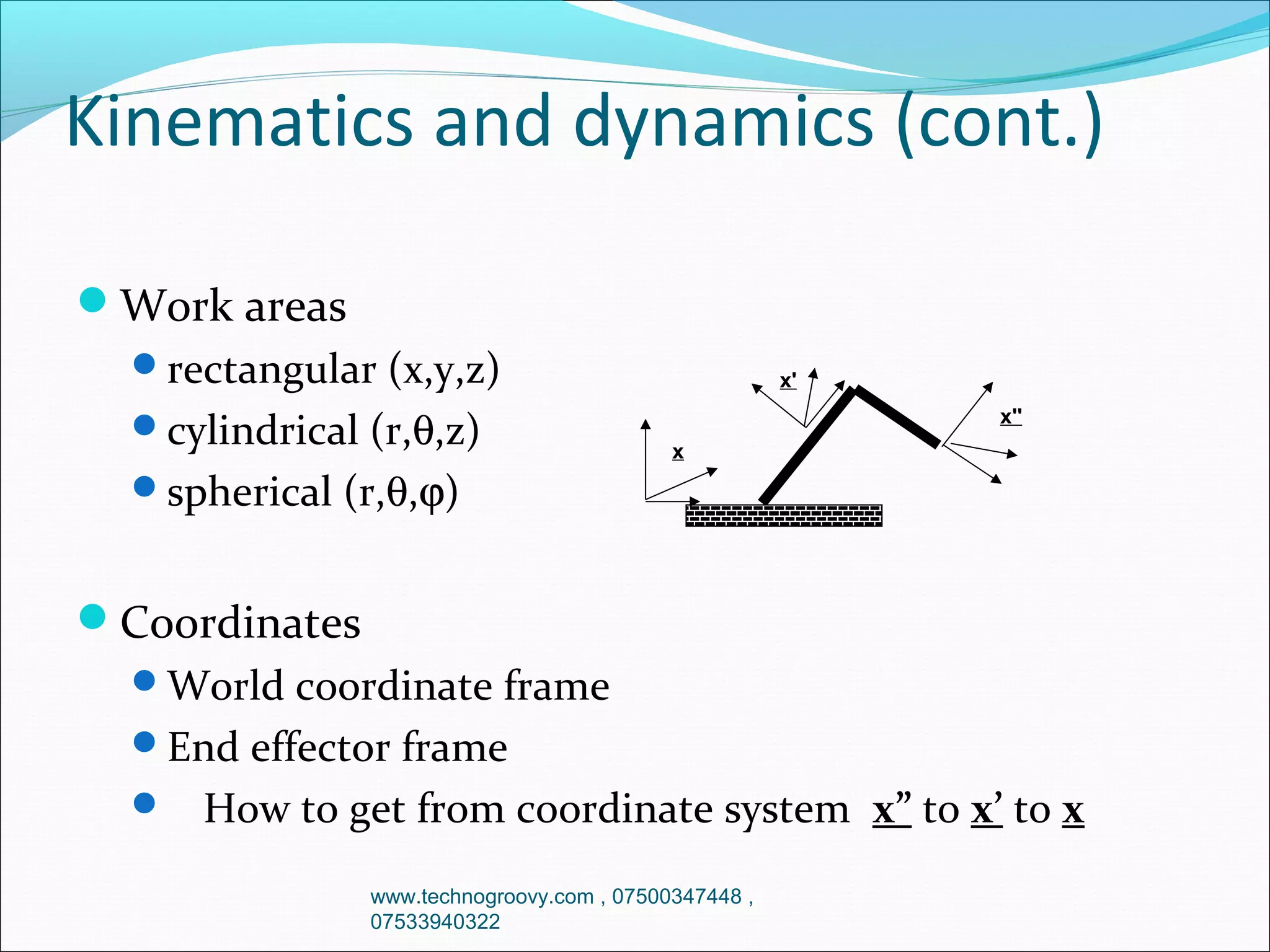

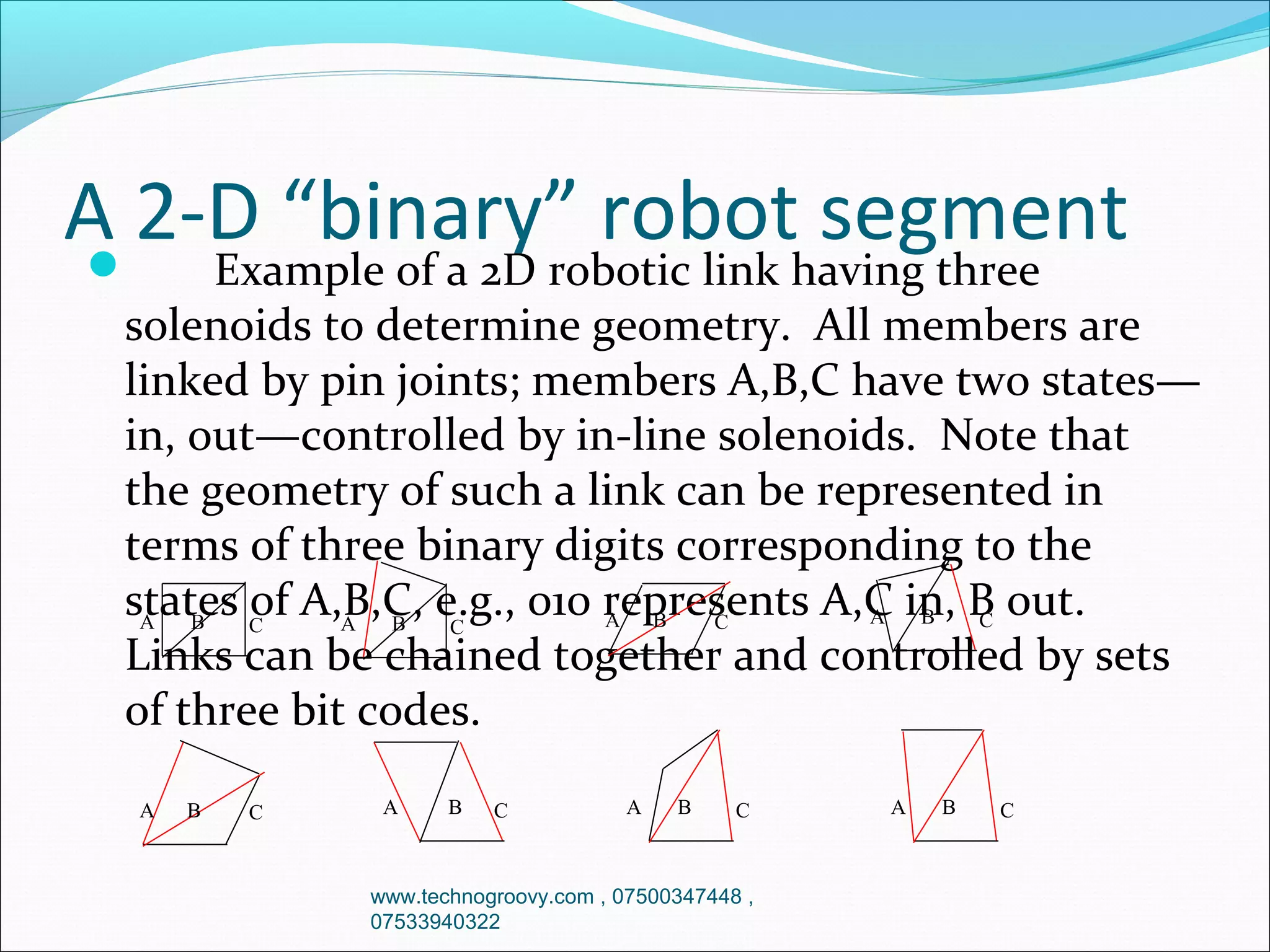

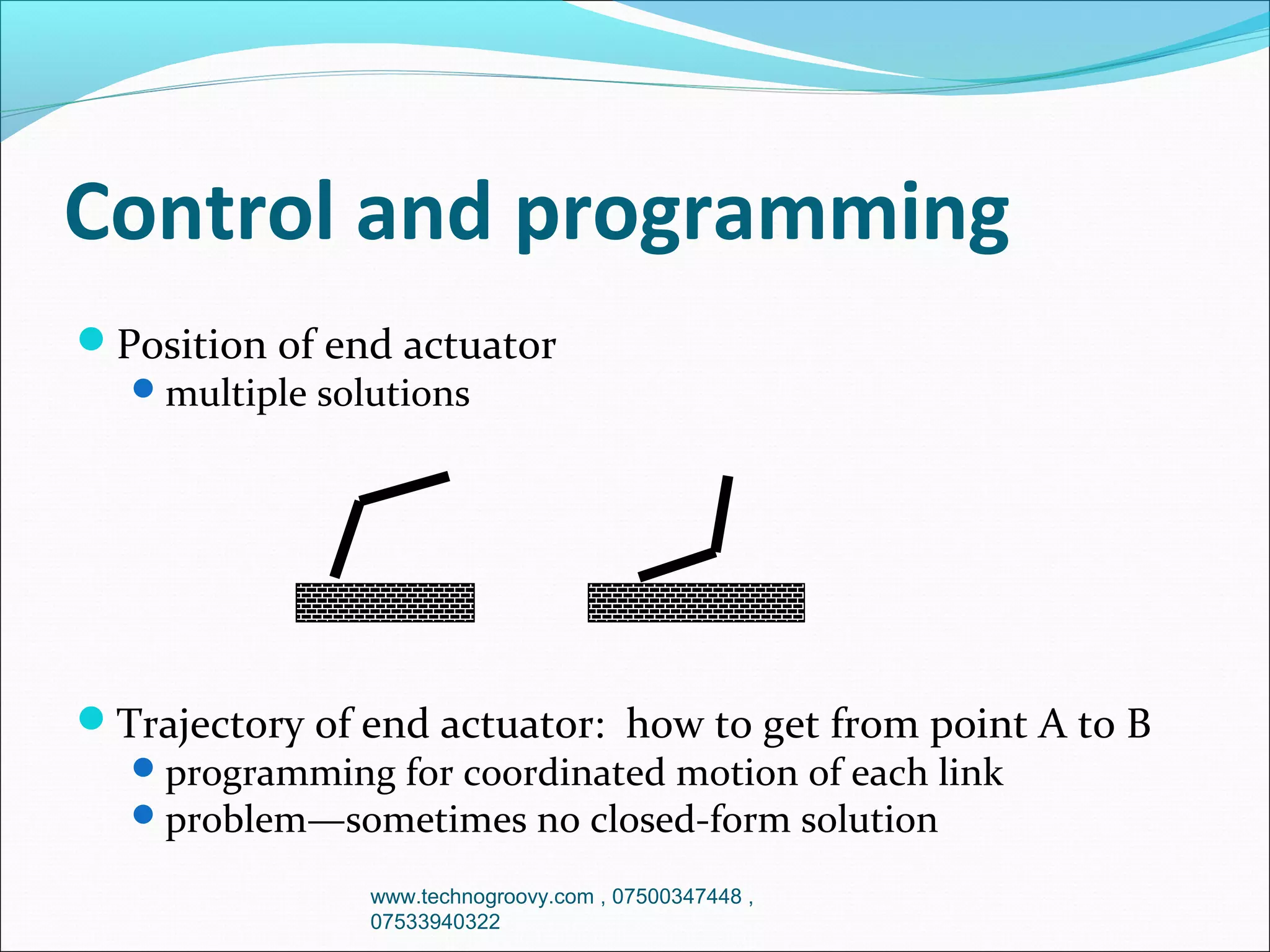

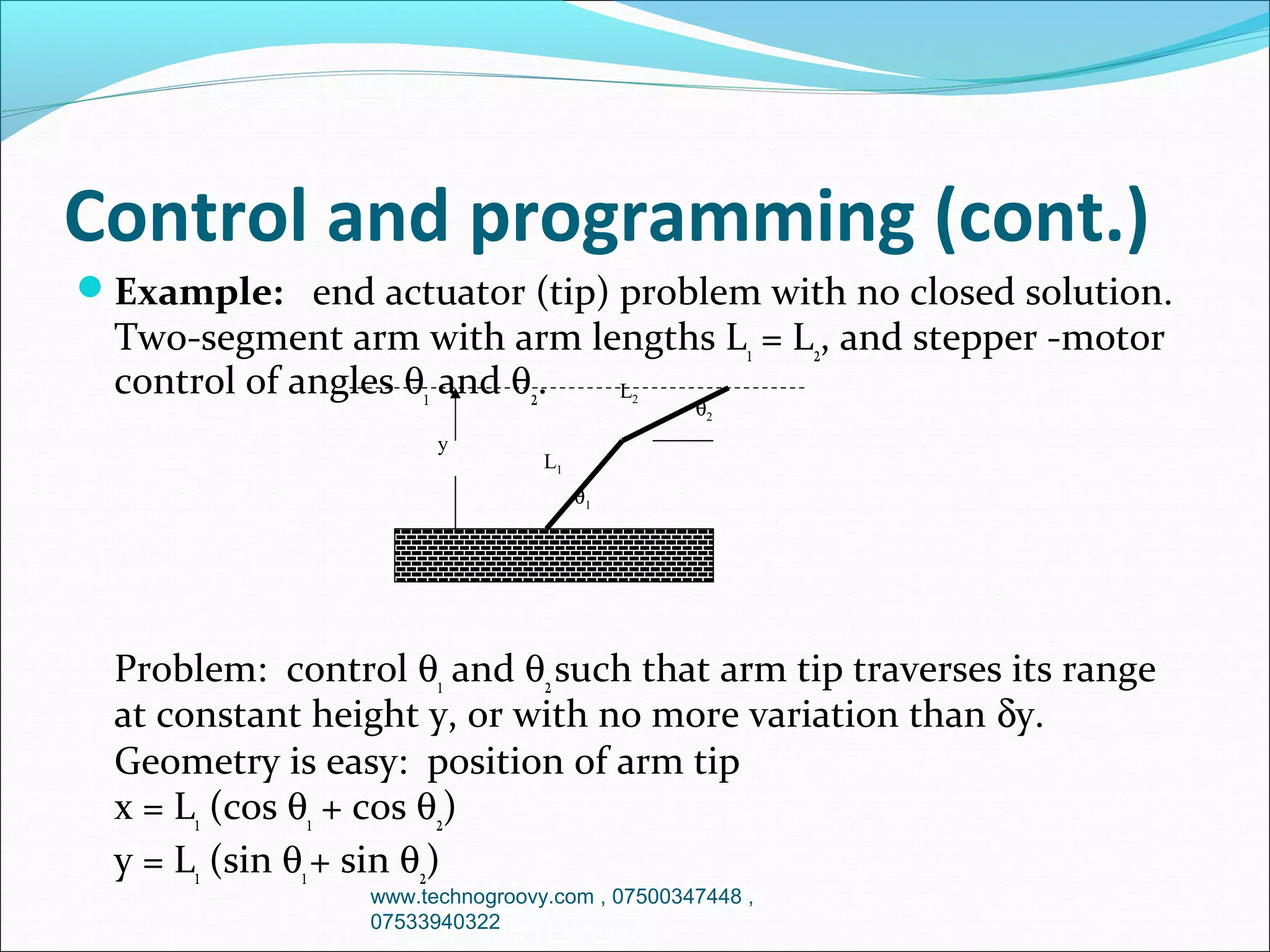

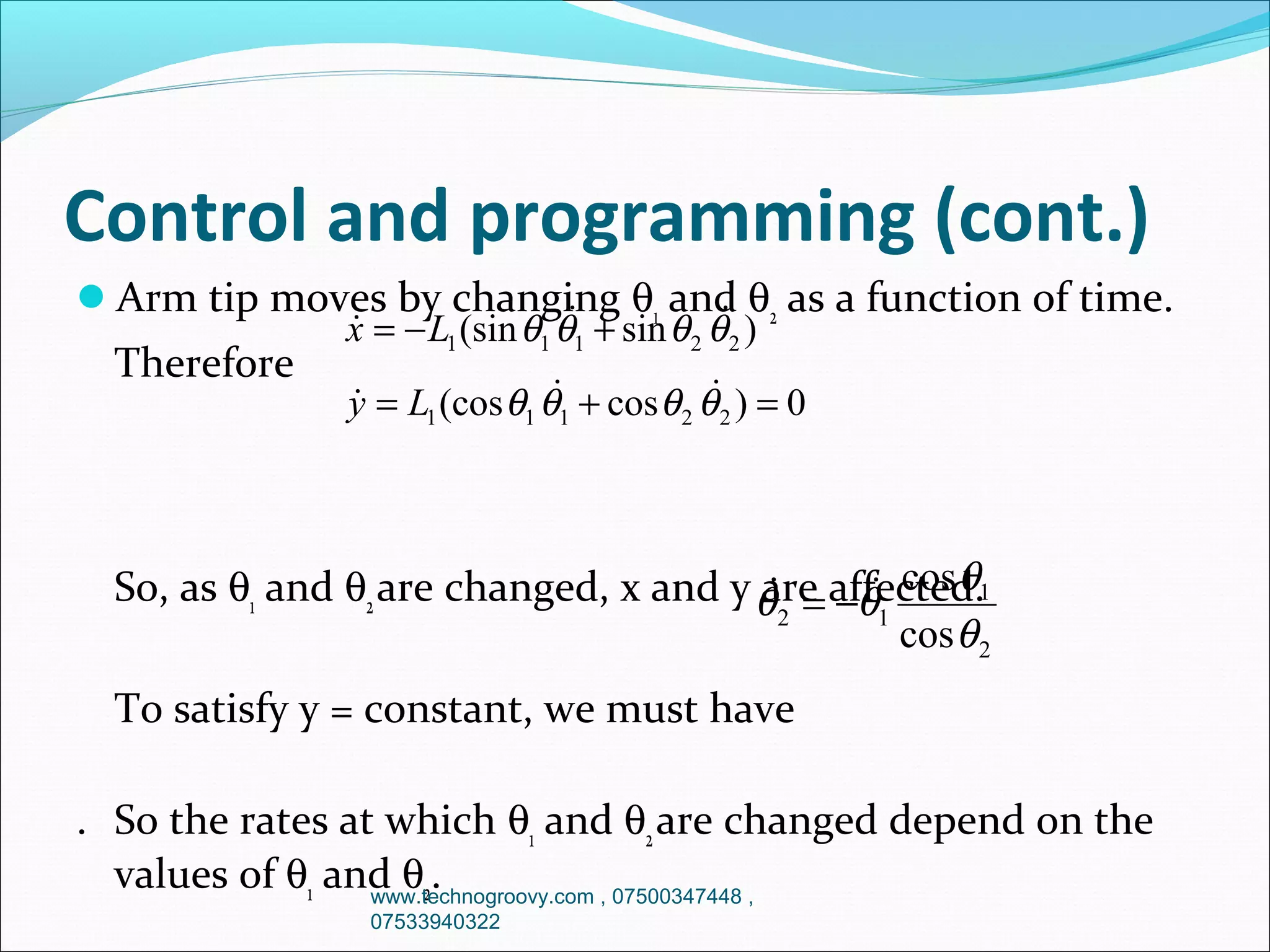

The document provides an overview of robots, defining them as machinery capable of performing various tasks such as dangerous operations, assembly line work, and precision machining. It discusses different types of robots, their control mechanisms, kinematics, dynamics, and performance measures, including accuracy and repeatability. Additionally, it touches on programming challenges and innovations in robotics, such as haptic feedback and robots capable of learning.