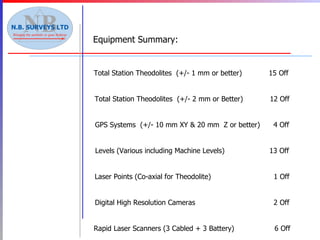

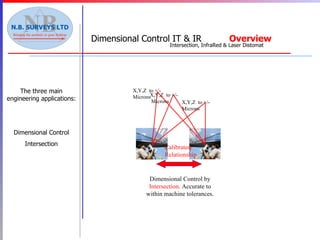

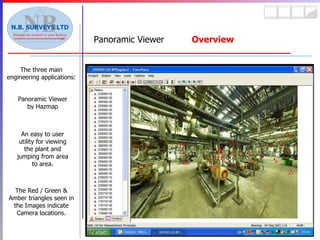

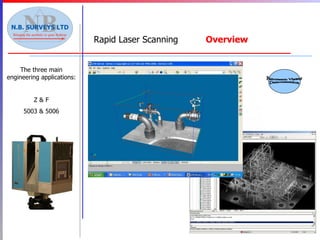

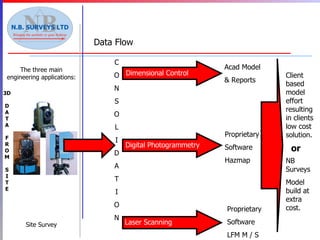

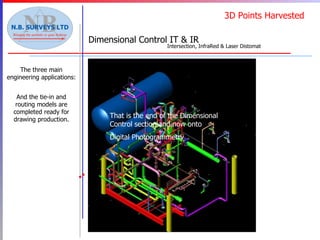

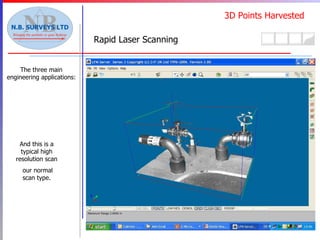

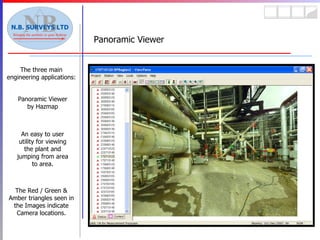

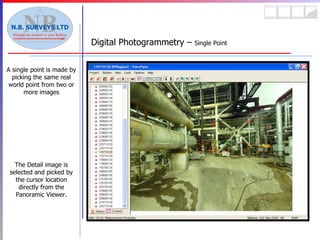

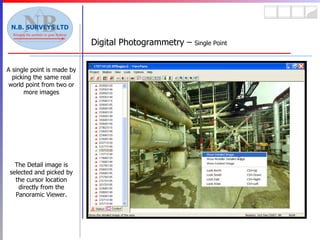

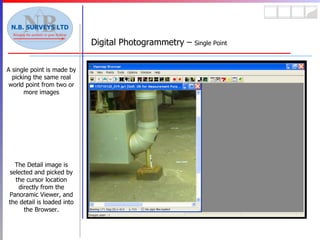

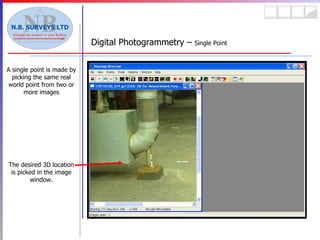

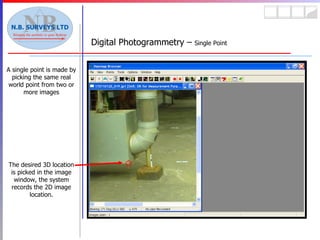

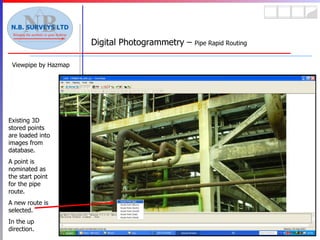

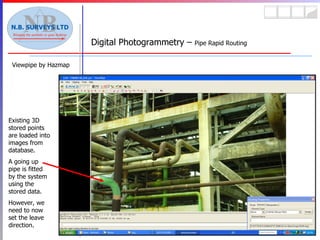

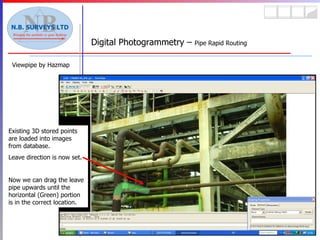

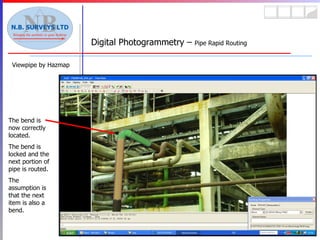

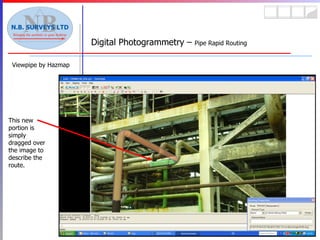

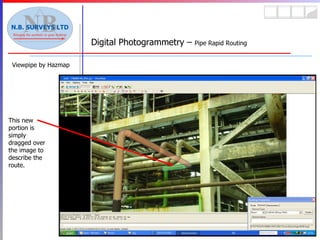

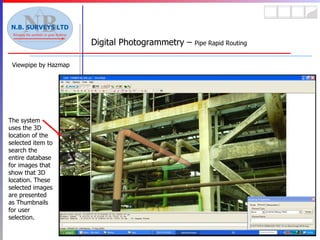

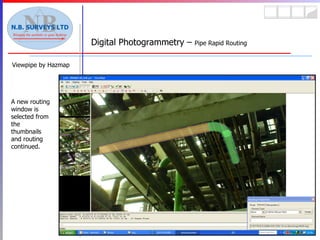

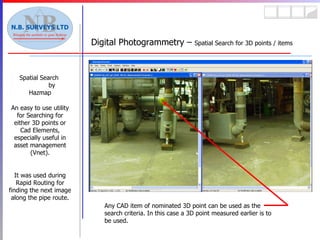

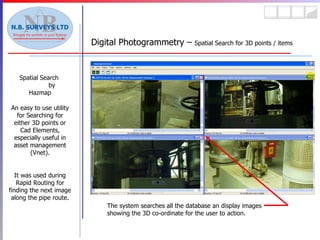

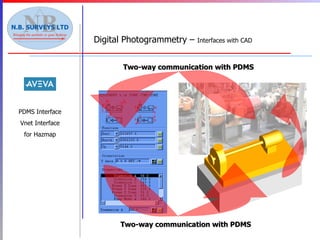

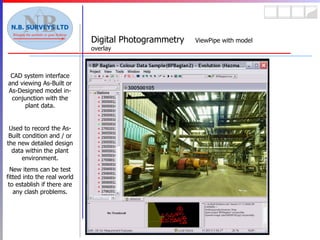

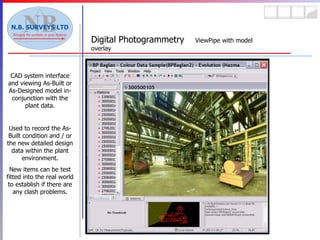

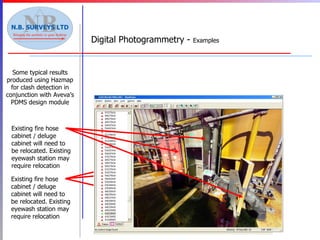

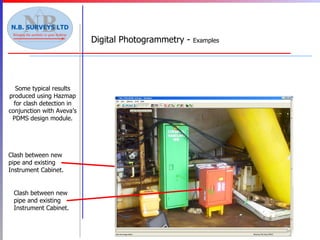

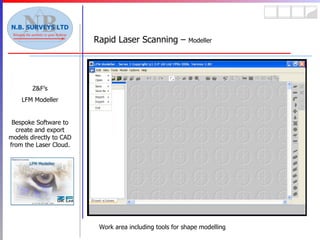

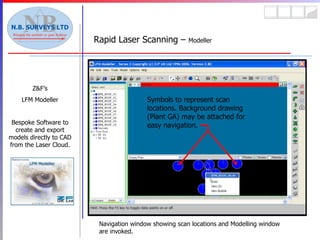

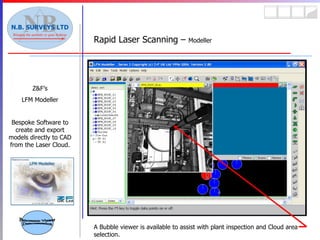

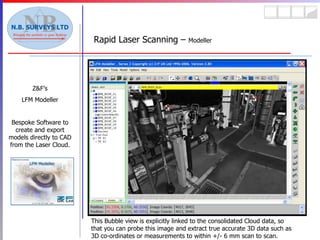

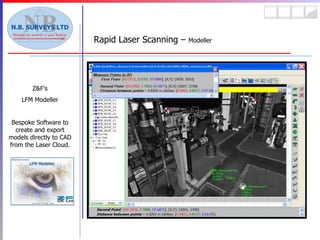

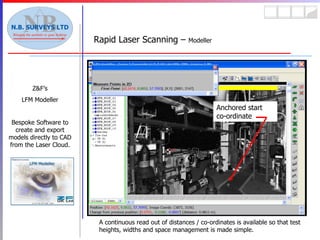

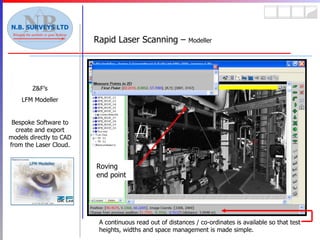

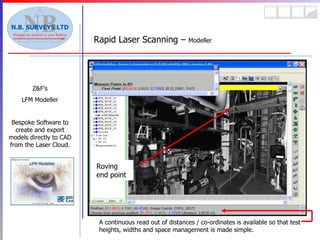

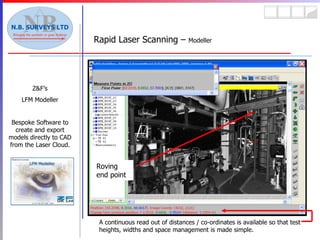

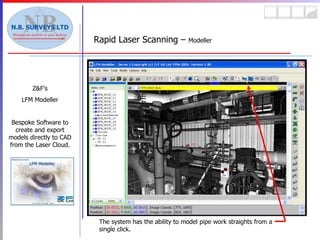

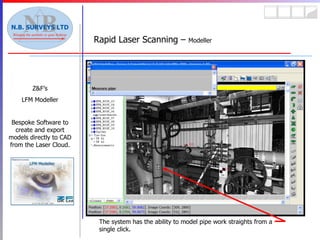

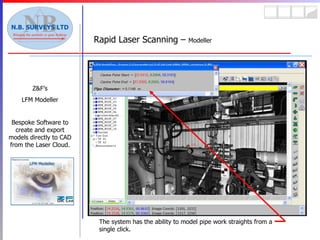

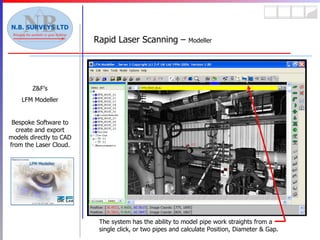

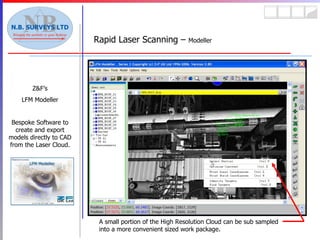

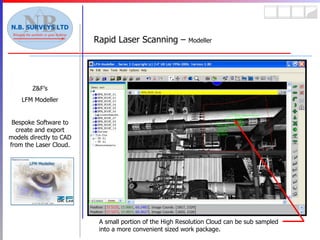

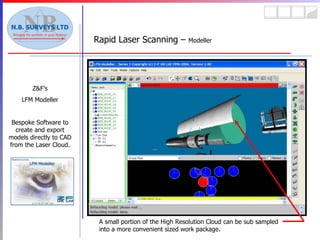

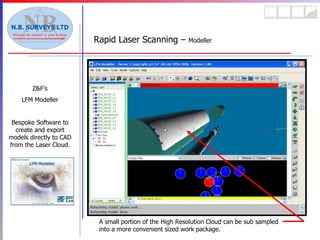

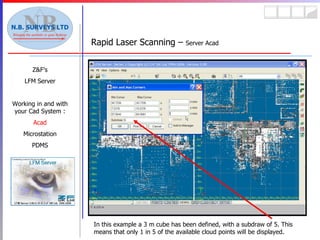

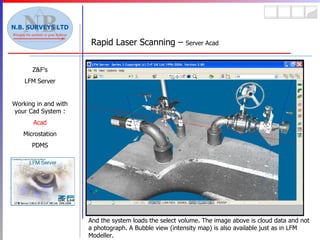

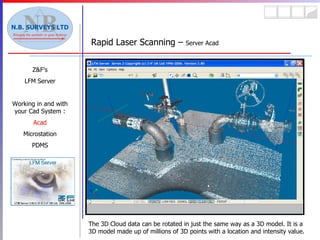

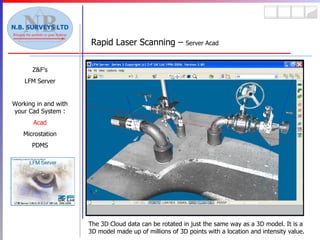

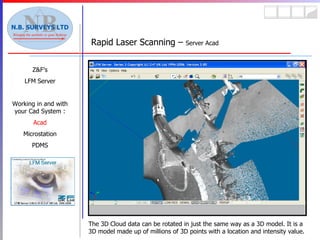

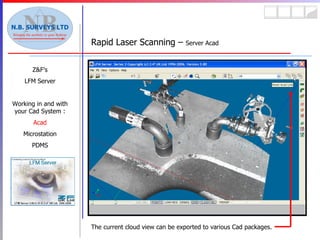

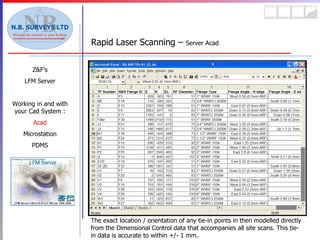

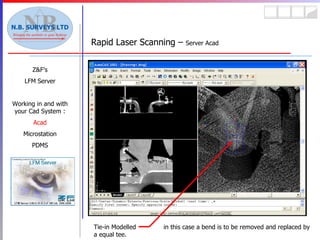

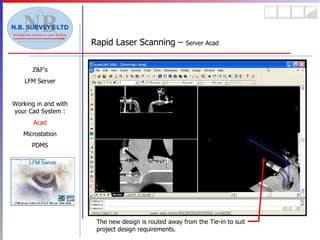

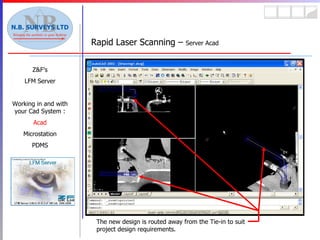

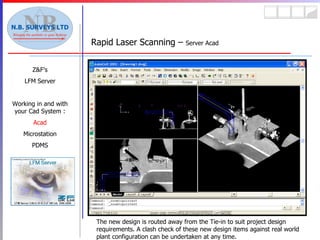

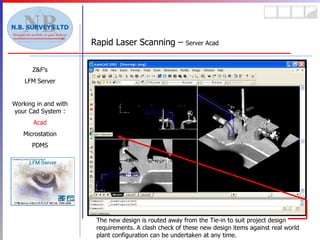

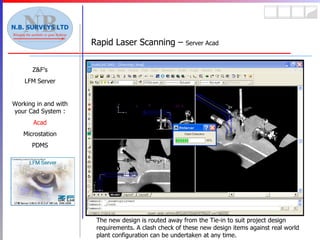

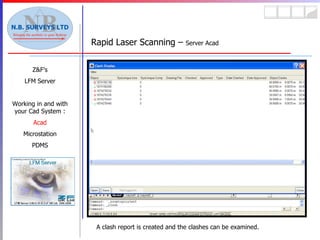

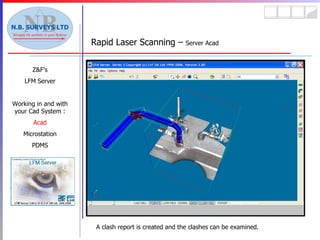

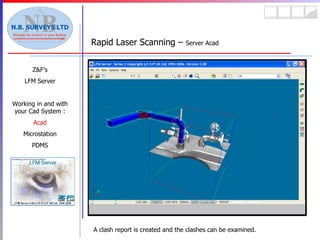

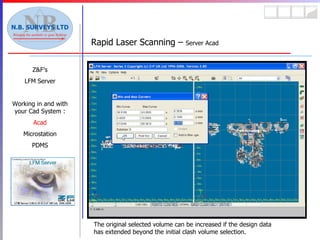

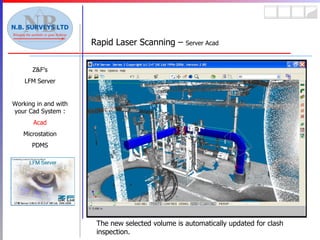

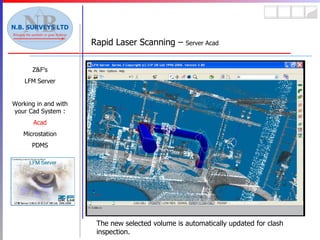

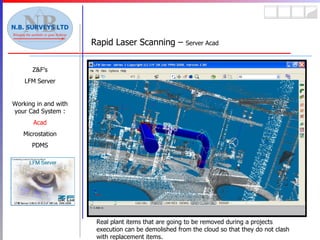

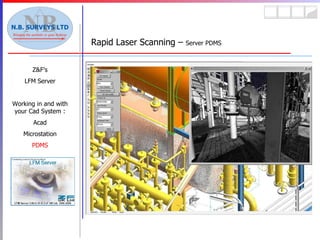

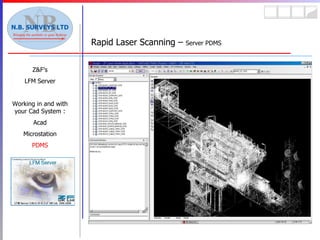

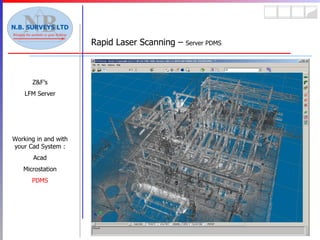

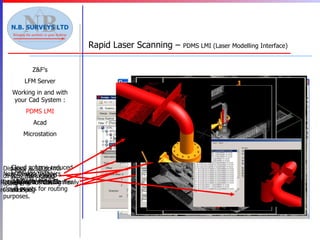

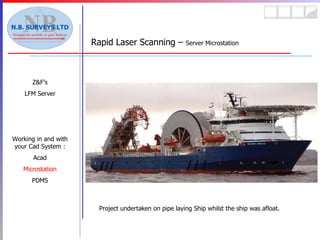

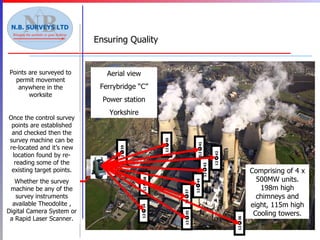

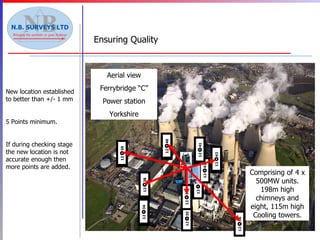

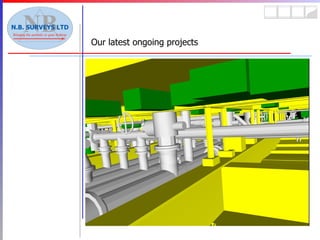

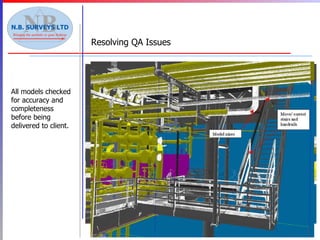

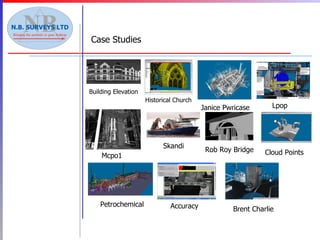

NB Surveys Ltd, established in 1982, provides surveying services to the oil and gas industries globally, utilizing advanced technologies like laser scanning and digital photogrammetry. They offer a range of deliverables including topographic, hydrographic, and building surveys, with a focus on accurate dimensional control and visualization through proprietary software. The presentation includes interactive elements and showcases their capabilities, equipment, and customer applications in both onshore and offshore environments.