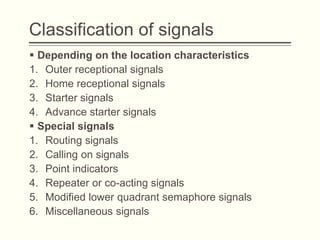

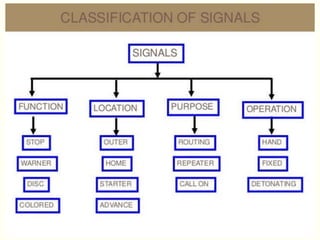

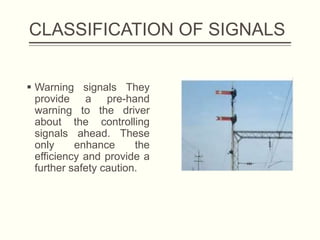

This document discusses railway signaling and interlocking systems. It begins by introducing the purpose of signaling in controlling train movements safely and efficiently. It then classifies signals based on their operational, functional and location characteristics. The document also describes different signaling systems like absolute block, space interval and time interval systems. It explains various types of signals like semaphore, warner and colored light signals. Finally, it discusses interlocking systems which prevent unsafe train movements at junctions and crossings, including key, mechanical, electrical, panel and route interlocking systems.