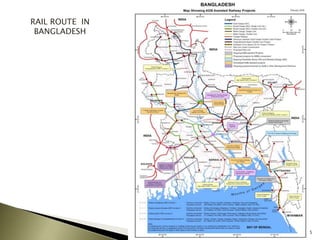

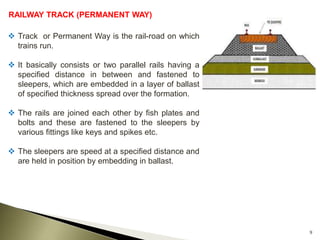

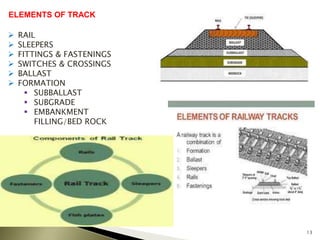

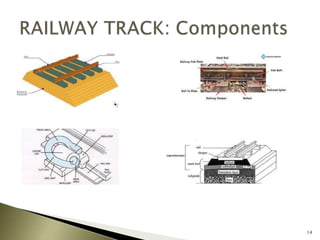

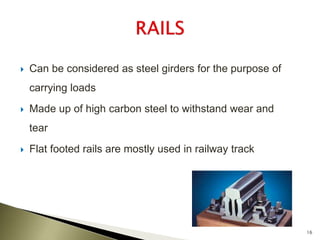

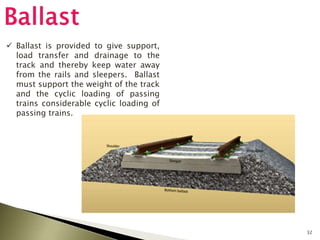

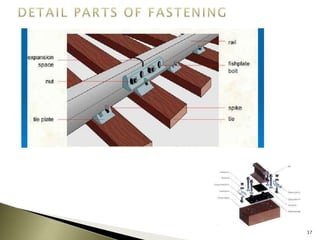

Bangladesh Railway started in 1862 with a 53 km broad gauge line. It now has over 2900 km of track with both meter gauge and broad gauge lines. The railway network connects 43 districts and is an important mode of transportation. Track consists of rails, sleepers, fittings and ballast laid on a prepared formation. Rails are joined by fish plates and bolted to sleepers. Ballast distributes loads and provides drainage. The master plan aims to upgrade tracks and convert more lines to broad gauge over the next two decades.