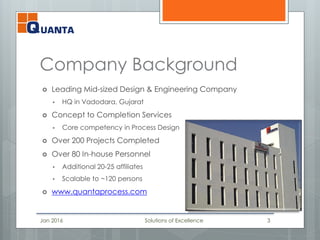

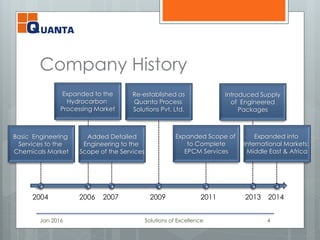

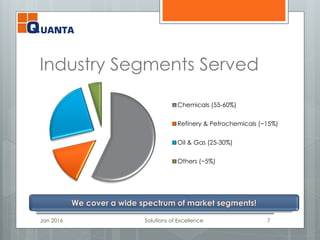

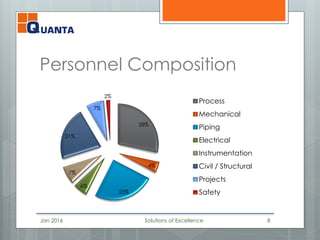

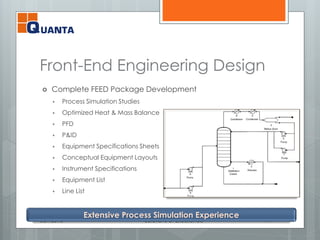

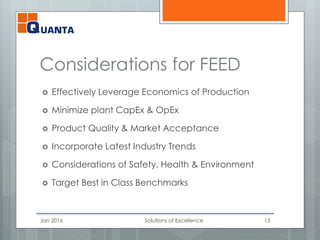

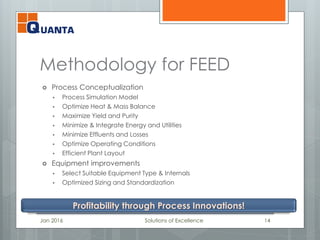

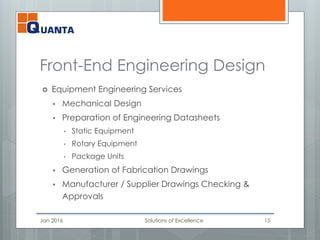

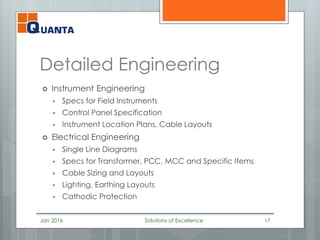

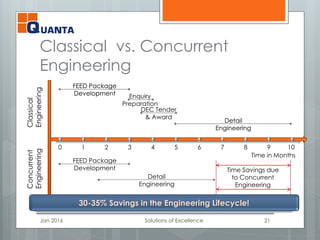

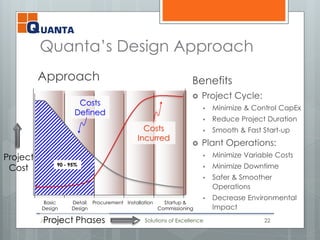

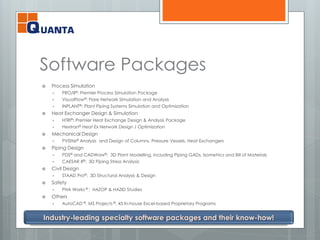

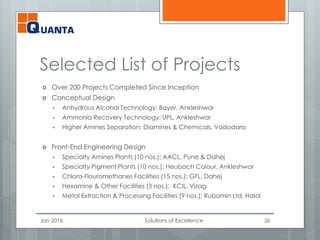

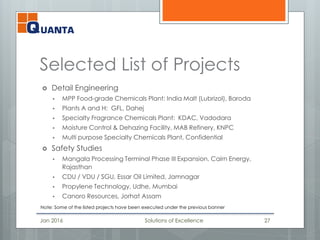

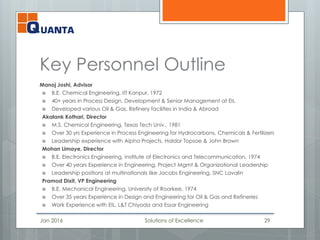

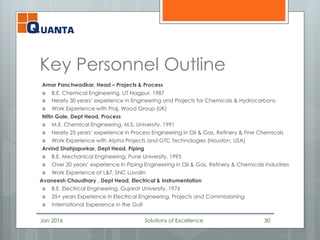

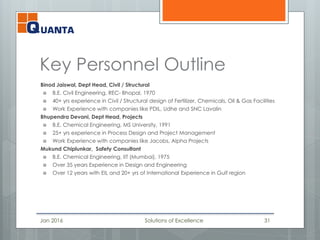

This document provides an overview of Process Solutions P Ltd, an engineering company. It discusses the company's background and capabilities in areas such as conceptual design, front-end engineering design, and detailed engineering for the chemicals, refinery, oil and gas industries. It also outlines the company's key personnel, software tools, project history with clients, and strengths in areas like safety studies and concurrent engineering. The presentation aims to showcase how the company takes projects from concept to completion with a flexible approach.