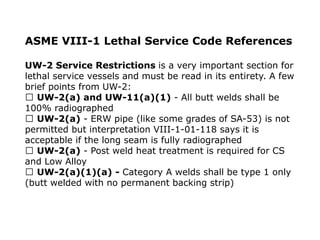

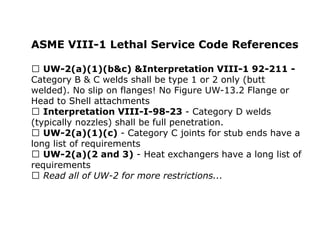

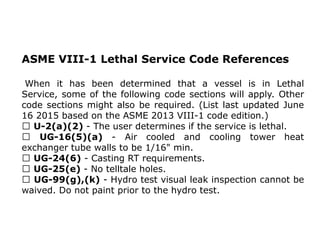

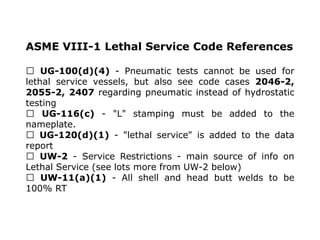

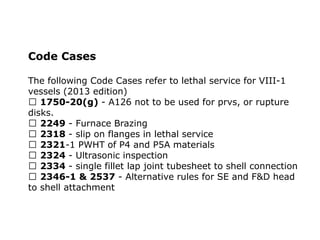

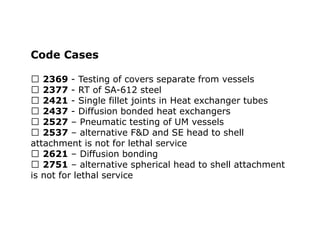

This document provides an overview of the ASME VIII Div. 1 code requirements for vessels in lethal service. It defines lethal service and lists the key sections of the code that apply, including UW-2 which has most of the lethal service requirements. Some of the major requirements mentioned are 100% radiography of all butt welds, restrictions on materials and joints allowed, and special marking and documentation. It also lists some relevant code cases and interpretations that relate to lethal service requirements.

![Introductions

Requirements for lethal service are scattered through

VIII-1, the code cases and the interpretations. ASME VIII-

1 section UW-2 has most of the requirements for lethal

service. Two definitions of lethal service are provided in

UW-2. The second definition is also duplicated in the end

notes:

[A] vessel is to contain fluids of such a nature that a very

small amount mixed or unmixed with air is dangerous to

life when inhaled[.]](https://image.slidesharecdn.com/lethalservice-quickguide-151207174118-lva1-app6891/85/Lethal-service-quick-guide-2-320.jpg)