This document provides a summary of an Indian Standard code of practice for the design, fabrication, and erection of vertical mild steel cylindrical welded oil storage tanks. The standard covers general requirements, materials, permissible stresses, design considerations for foundations, bottom plates, shell plates, roofs, and floating roofs. It also addresses appurtenances and mountings, shop fabrication and inspection, site erection, site welding, radiographic inspection of shell joints, and testing of tanks. Tables and figures are provided to illustrate typical tank components and specifications. The standard aims to promote transparency and accountability in public works by making this safety information publicly available.

![Disclosure to Promote the Right To Information

Whereas the Parliament of India has set out to provide a practical regime of right to

information for citizens to secure access to information under the control of public authorities,

in order to promote transparency and accountability in the working of every public authority,

and whereas the attached publication of the Bureau of Indian Standards is of particular interest

to the public, particularly disadvantaged communities and those engaged in the pursuit of

education and knowledge, the attached public safety standard is made available to promote the

timely dissemination of this information in an accurate manner to the public.

इंटरनेट मानक

“!ान $ एक न' भारत का +नम-ण”

Satyanarayan Gangaram Pitroda

“Invent a New India Using Knowledge”

“प0रा1 को छोड न' 5 तरफ”

Jawaharlal Nehru

“Step Out From the Old to the New”

“जान1 का अ+धकार, जी1 का अ+धकार”

Mazdoor Kisan Shakti Sangathan

“The Right to Information, The Right to Live”

“!ान एक ऐसा खजाना > जो कभी च0राया नहB जा सकता है”

Bhartṛhari—Nītiśatakam

“Knowledge is such a treasure which cannot be stolen”

“Invent a New India Using Knowledge”

है”ह”ह

IS 803 (1976): Code of Practice for Design Fabrication and

Erection of Vertical Mild Steel Cylindrical Welded Oil

Storage Tanks [CED 7: Structural Engineering and structural

sections]](https://image.slidesharecdn.com/is-160425153502/75/Is-803-1976-1-2048.jpg)

![IS : 303- 1976

CONTENTS

L’.

1.

2.

3.

4.

5.

6.

7.

8.

9.

1’5.

11.

12.

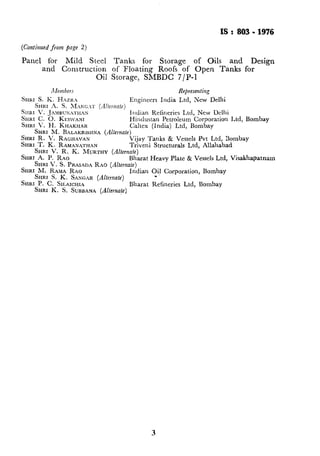

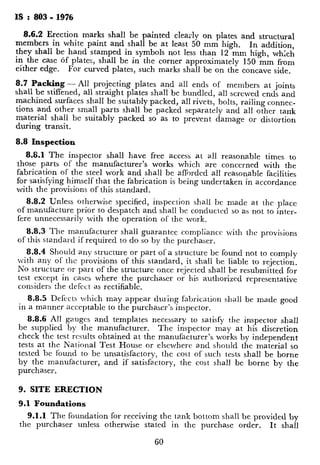

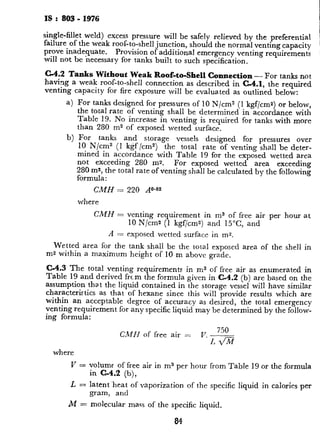

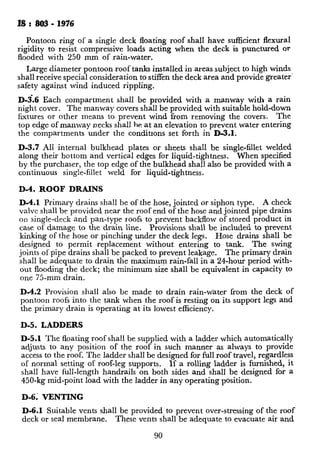

FOREWORD . . . . . .

SCOPE . . . . . .

DEFINITIONSANDSYMBOLS . *

GENERAL . . . . . .

MATERIALS . . . . . .

PERMISSIBLESTRESSES . . . .

DESIGN . . . . . .

6.1 Foundation . . . .

6.2 Design of Bottom Plates . .

6.3 Design of Shell Plates . .

6.4 Designs of Roof . . . .

6.5 Floating Roof . . . .

APPURTENANCESANDMOUNTINGS . .

SHOPFABRICATIONAND INSPECTION . .

SITE ERECTION . . . .

SITEWELDING . . * .

RADIOGRAPHICINSPECTIONOFSHELLJOINTS

TESTINGOFTANKS . . . .

12.1 Bottom Testing . . . .

12.2 Shell Testing . . . .

12.3 Fixed Roof Testing . . . .

12.4 Repair of Leaks . . . .

. .

. .

. .

. .

. .

. .

. .

. .

. .

. .

. .

. .

. .

. .

. .

. .

. .

. .

. .

. .

. .

. .

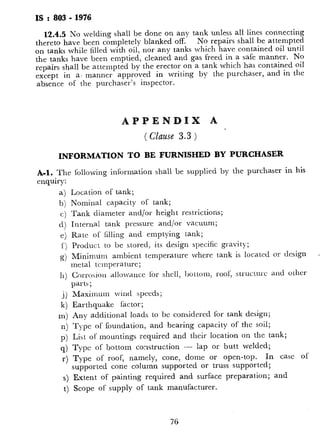

APPENDIXA INFORMATION‘1‘0 13~ FURNISHEUBY PURCHASER

.IPPENDIXB AL.TERNA~.EDESI~~NFOR TANK SHELLS . .

. .

. .

. *

. .

. .

. .

. .

. .

. .

. .

. .

. .

. .

. .

. .

. .

. .

. .

. .

. .

. .

. .

. .

. .

APPENDIXC Va~r SIZING I’OR AYMOSPHERICAND Low PRESSURE

TA~XKS . . . . . . . . . .

APPENDIXD ~:LOA?.INGROOFS . . . . . .

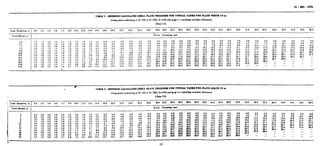

TABLES 1-3 NOAUNALCAPACITIESOFTYPICALTANKS . . . .

TABLES 4-6 MINIMUM CALCULATEDSHELL PLATE THICKNESSFOR

TYPICAL TANKS . . . . . .

PAGE

6

7

7

10

10

16

16

17

17

5:39

39

49

60

63

65

69

69

:i

70

76 *

77

82

88

II-12

12-13

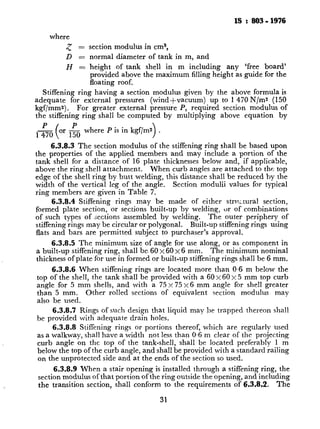

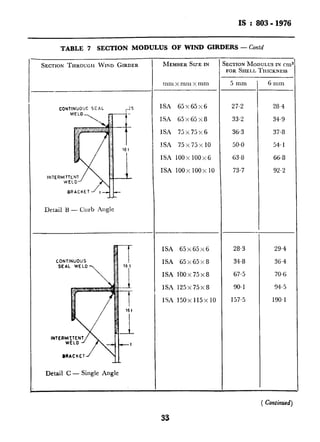

TABLE 7 SECTIONMODULUSOFWIXD GIRDERS . . . . 32-35

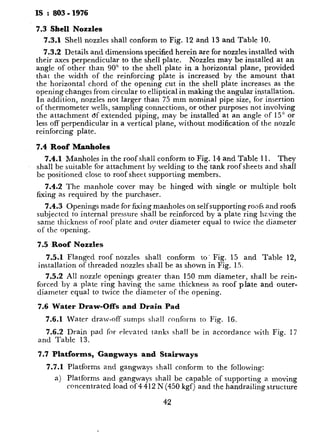

TABLE 8 SHELLMANHOLECOVER PLATEANDBOLTINGFLANGE

THICKNESS . .

4

. . . . . . 45

TABLE 9 SHELLMANHOLEDIMENSIONALDATA . . . . 46

TABLE 10 SHELLNOZZLESDIMEI~SIONALDATA . . . . 50-51

TABLE 11 ROOF MANHOLES * . . . . . 51

TABLE 12 ROOF NOZZLES . . . . . . 52

TARLE 13

TABLE 14

TABLE I5

TABLE 16

TABLE 17

TABLE 18

TABLE 19

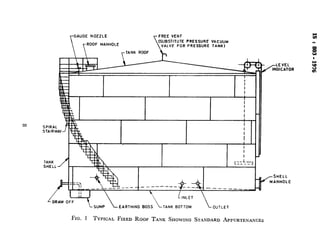

FIGURE 1

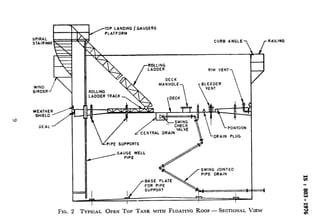

~FIGuRE 2

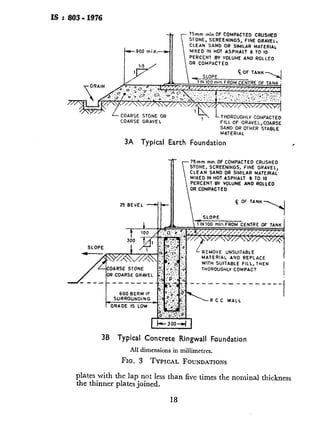

FIGURE 3

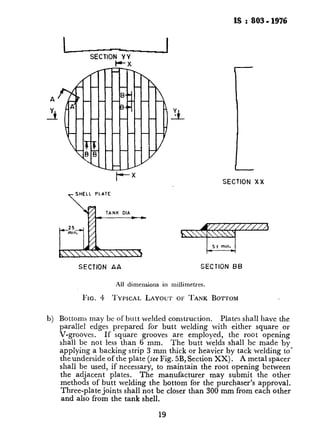

FIGURE 4

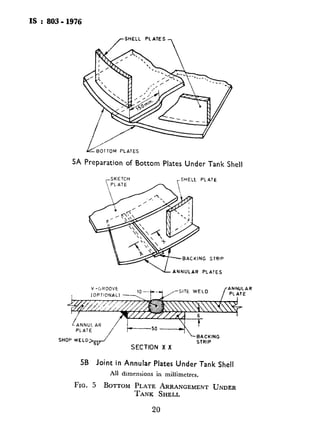

FIGURE 5

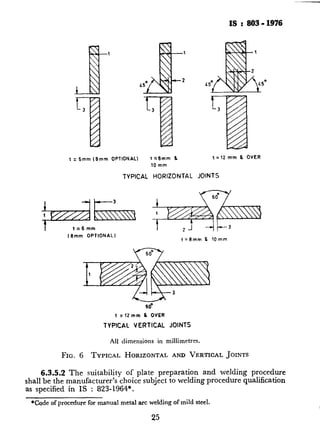

FIGURE 6

FIGURE 7

FIGURE 8

FIGURE .9

FIGURE 10

FIGURE 11

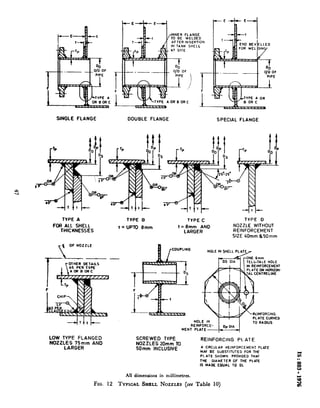

FIGURE 12

FIGURE 13

FIGURE 14

FIGURE 15

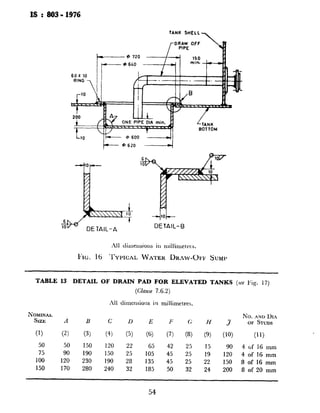

FIGURE 16

FIGURE 17

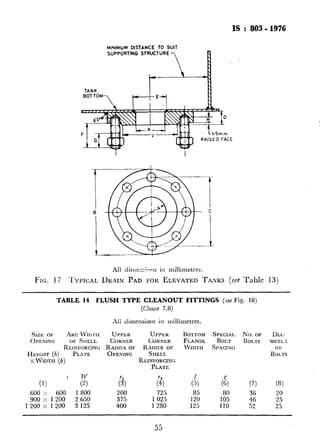

FIGURE I8

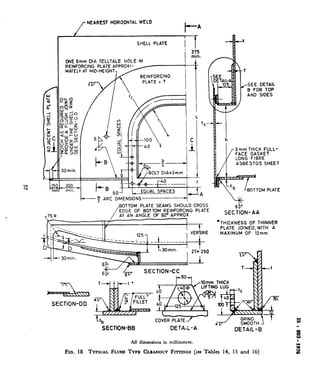

FIGURE 19

DETAIL OFDRAIN PA

FLUSHTYPE CLEANO

TIIUXNESSOF~COVER

FORCINGPLATEFORI

THICKNESSAND HEIC

FORCLEANOUTFITTII

MAXIMUMPERMISSII~L

GRAPHSPER I50 mm

THERMALVENTINGC

TOTAL RATE OF EME

FIRE EXPOSUREVERS.

TYPICALFIXEDROOF

TENANCES . .

TYPICAL OPEN .To

- SECTIONALVIEW

TYPICALFOUNDATION

TYPICAL LAYOUT OF’

BOTTO~~IPLATEARRA:

TYPICALHORIZONTAI

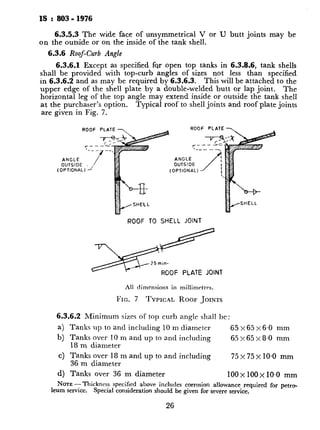

TYPICALROOFJOINT!

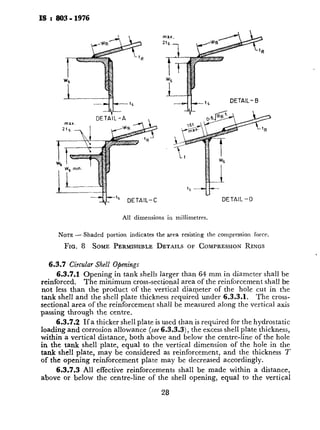

SOUSEPERMISSIBLEDE

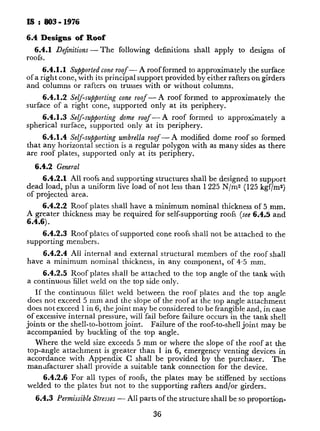

RECOMMENDEDLAYO~

TANKS . . . .

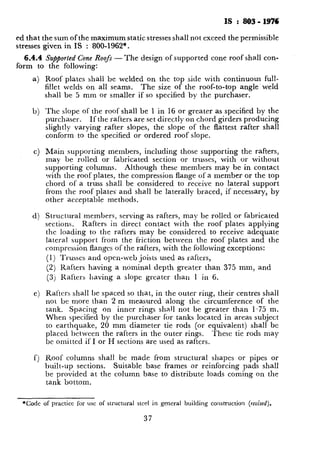

TYPICALCOLUMNANT

TYPICAL SHELLMAN:

TYPICALSHELLNozz

SHELLNOZZLE FLANGE

TYPICALROOF MANHC

TYPICALROOF NOZZLE

TYPICALWATER DRAM

TYPICALDRAIN PAD F

TYPICAL FLUSHTYPE

TYPICAL GAUGE-WE]

NOZZLE OF CONE Roo:

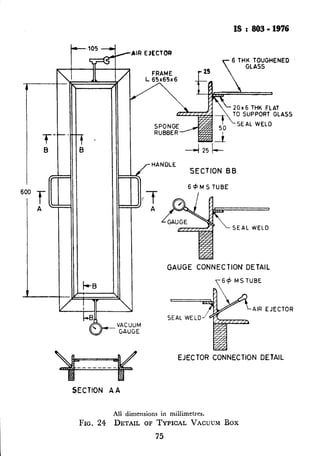

FIGURES20-23 RADIOGRAPHICPORN

FIGURE24 DETAILOFTYPICALV

FIGURE25 INSERT TYPE REINFN

NOZZLES . .

4](https://image.slidesharecdn.com/is-160425153502/85/Is-803-1976-8-320.jpg)

![IS : So3 - 1976

(or operator) has welded. If any of such additional spots fails to comply

with the requirements of 11.7, the limits of unacceptable welding shall be

determined as specified for the initial section.

11.9 Repair of Defective Welds - Defects in welds shall be repaired by

chipping or melting OULsuch defects ftom one or from both sides of the

joint, as required, and rewelding. Only sufficient cutting out of defective

joints is required as is necessary to correct the defects,

All repaired welds in joints shall be checked by repeating the original test

procedure.

11.10 Record of Radiographic Examination - A record shall be made

by the erector of.all films, with their identification marks, on a developed

shell plate diagram.

After the completion of the structure, the films shall be the property of

the purchaser, unless otherwise agreed between the purchaser and the

erector.

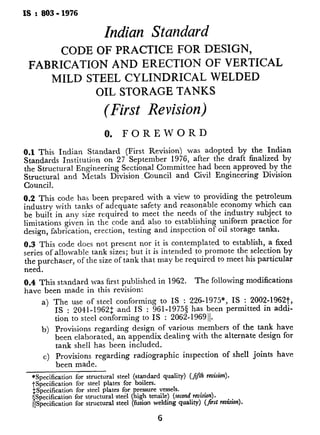

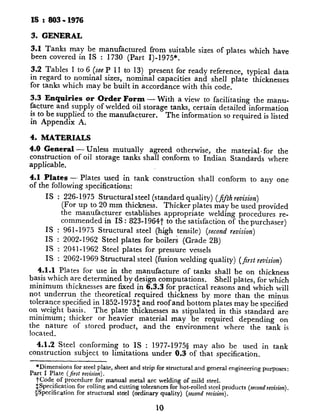

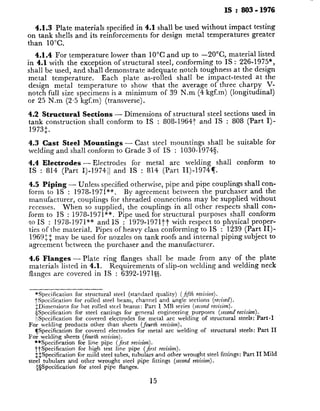

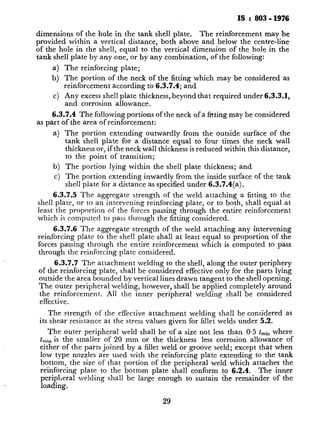

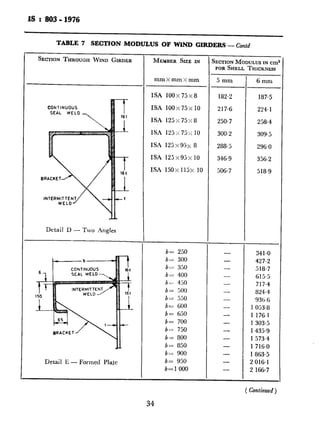

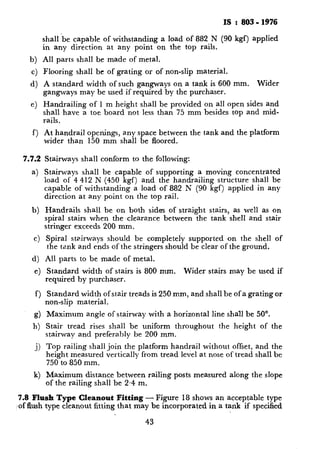

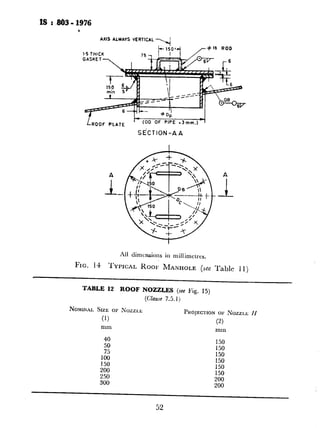

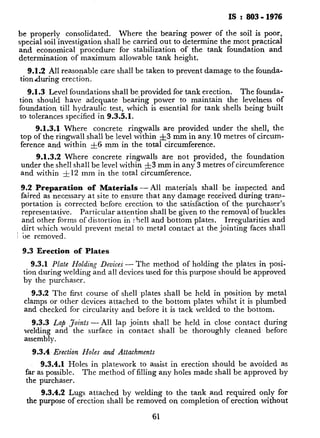

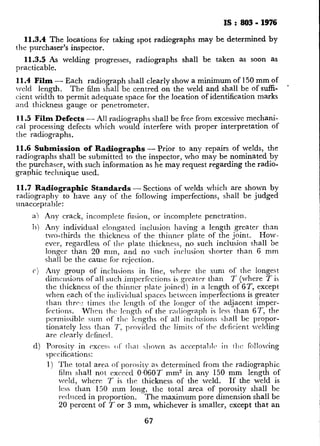

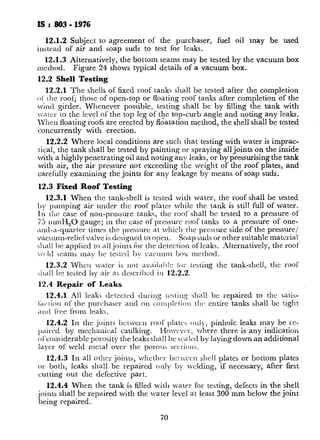

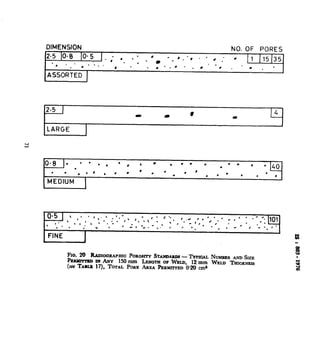

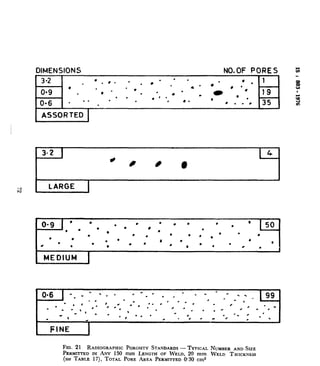

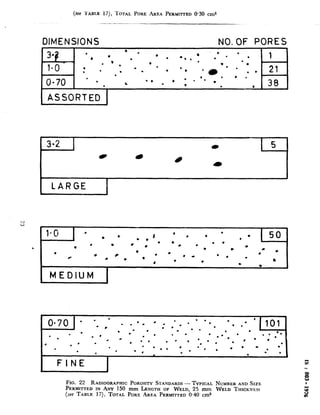

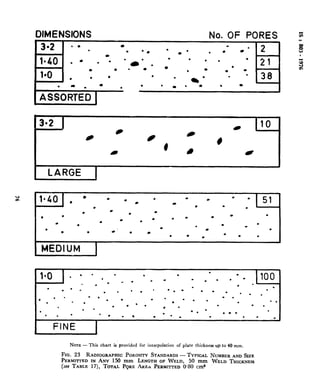

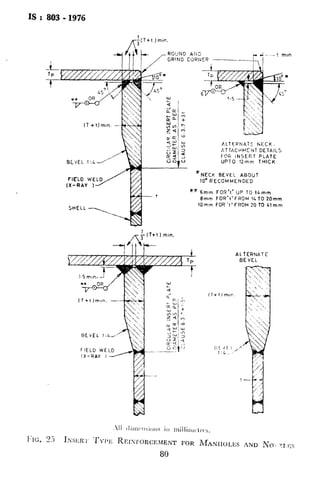

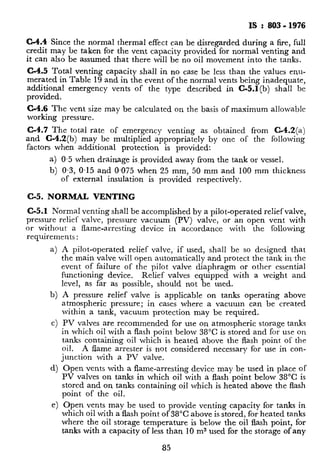

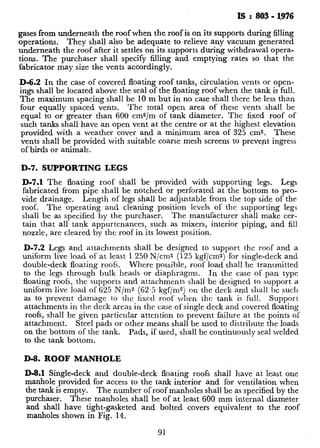

TABLE 17 MAXIMUM PERMISSIBLE POROSITY INDICATIONS IN

RADlOGRAPHS PER 150 mm LENGTH OF WELD (see Fig. ‘20 to 23)

[Ch.se 1$7(d)(5)]

WELD TOTALAREA LARGEPORES MEDIUMPORE FINE PORE

THICKNESS OFPERMITTED

POROSITY ?z- zkzz xz---T l-----J-Number Size Number

(1) (2) (3) (4) (5) (6) .. (7) (8)

cm2 mm mm mm

3 0.05 - - - - 0.40 40

6 0.10 - - 0.6 31 0.40 100

12 0.20 2.5 4, 0.80 40 0.50 101

20 0.30 3.2 4 0,90 50 0.6U 99

25 0.40 3.2 5 I.0 50 0.70 101

40 0.60 3.2 7 1.20 50 0.90 99

50 0.80 3.2 IO 1.4 51 1.0 100

12. TESTING OF TANKS

12.1 Bottom Testing

12.1.1 After the bottom and at least the bottom course of shell plates

have been welded, the bottom shall be tested by pumping air beneath the

bottom plates to a pressure just sufficient to lift them off the foundation

and in any case, not less than 100 mmH,O gauge. The pressure shall be

held by the construction of a temporary dam of clay or other suitable

material around the tank periphery. Soap suds or other suitable material

shall be applied to all joints for detection of leaks.

69](https://image.slidesharecdn.com/is-160425153502/85/Is-803-1976-73-320.jpg)

![IS : 803 - I976

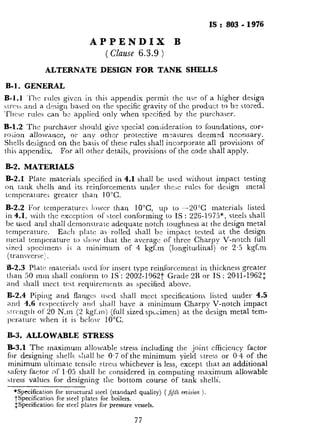

B-4. PLATE THICKNESS

B-4.1 The minimum thickness of shell plates shall not be less than that

calculated from the following formula or according to 6.3.3.2 whichever

is greater:

t = 4.9 (H - 0.3) D x G

S

+ c where S is in N/mm2

or

= 5’ (N - y) D ’ G + c where S is in kgf/cms

where

t = minimum thickness in mm;

D = nominal diameter of tank in m;

N = height from the bottom of the course under consideration to

top curb angle or to bottom of any overflow which limits tank

filling height in m;

G = specific gravity of liquid to be stored;

S = allowable stress as computed from B-3.1; and

c = corrosion allowance in mm to be specified by purchaser, but not

less than 1.5 mm.

B-4.2 The manufacturer may use a combination of high strength steel for

lower courses and low strength steel for upper courses, provided that the

thickness of any course is not less than the course immediately above it.

B-5. HYDROSTATIC STRESSES

B-5.1 Stresses in plates due to hydrostatic loading shall not exceed 3/7 of

minimum ultimate tensile stress of the material used. Plate thicknesses

determined by B-4.1 or 6.3.3.2 shall be checked for hydrostatic stresses S,

by the following equation and shall be increased as required to keep it

within specified limits:

s

1

= 4.9 (H - 0.3) D

t

N/mm” < 3/7 Min UTS

or

= 5’ (H t o’3) D kgf/cm2 < 317 Min UTS

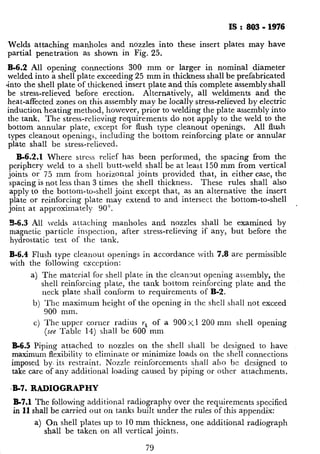

B-6. SHELL CONNECTIONS

B-6.1 All shell opening connections which require reinforcement shall be

attached by welds fully penetrating the shell. Where insert type rein-

forcements, shown in Fig. 25, are used, they shall be butt-welded into the

shell as shown, with the welds having complete penetration and fusion.

78

Welds attaching manholes and nozzles

partial penetration as shown in Fig. 2.

B-6.2 All opening connections 300 mr

welded into a shell plate exceeding 25 mr

-into the shell plate of thickened insert pl:

be stress-relieved before erection. Alto

heat-affected zones on this assembly may

induction heating method, however, prio

the tank. The stress-relieving requireme

bottom annular plate, except for flush t

types cleanout openings, including the bc

plate shall be stress-relieved.

B-6.2.1 Where stress relief has been

periphery weld to a shell butt-weld sha

joints or 75 mm from horizontal joints

spacing is not less than 3 times the shell

apply to the bottom-to-shell joint excep

plate or reinforcing plate may extend tm

joint at approximately 90”.

B-6.3 All welds attaching manholes a

magnetic particle inspection, after stre

hydrostatic test of the tank.

B-6.4 Flush type cleanout openings in ac

with the following exception:

a) The material for shell plate in t

shell reinforcing plate, the tank

neck plate shall conform to ret

b) The maximum height of the 01

900 mm.

c) The upper corner radius rt o

(see Table 14) shall be 600 ml

B-6.5 Piping attached to nozzles on tl

maximum flexibility to eliminate or mini

imposed by, its restraint. Nozzle reinfor

take care of any additional loading caus’

.B-7. RADIOGRAPHY

B-7.1 The following additional radiogra]

in 11 shall be carried out on tanks built I

a) On shell plates up to 10 mm tl

shall be taken on all vertical j

79](https://image.slidesharecdn.com/is-160425153502/85/Is-803-1976-82-320.jpg)

![IS: 803-1976

product, and for tanks with a capacity of less than 500 m3 used for

the storage of crude oil.

f) In the case of viscous oils, such as cutback and penetration grade

asphalts, where the danger of tank collapse resulting from sticking

pallets or from plugging of flame arrestors is greater than the possi-

bility of flame transmission into the tank, open vents may be used

as an exception to the requirement for PV valves or flame-arresting

devices as called for in (c) and (d) above.

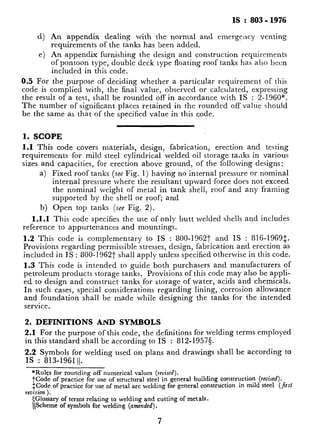

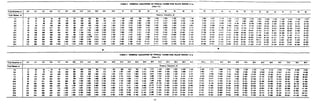

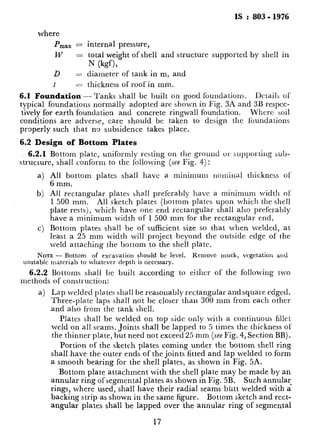

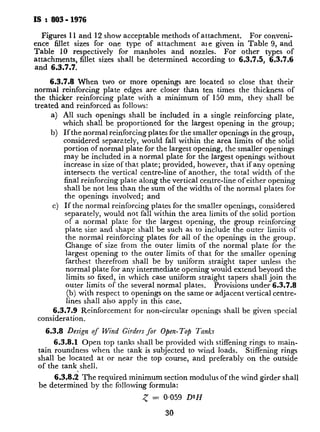

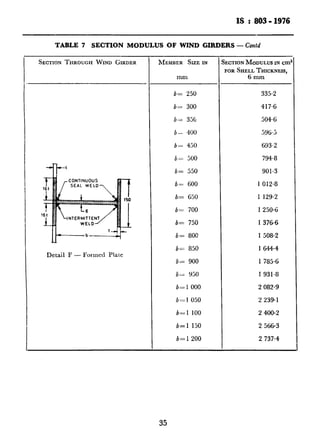

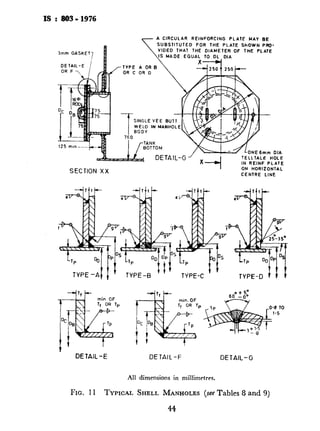

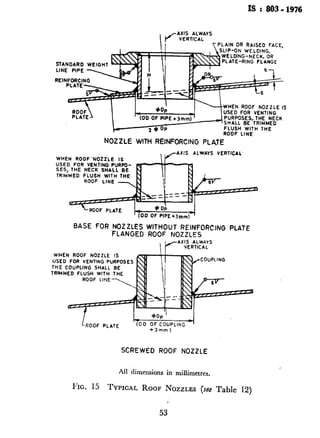

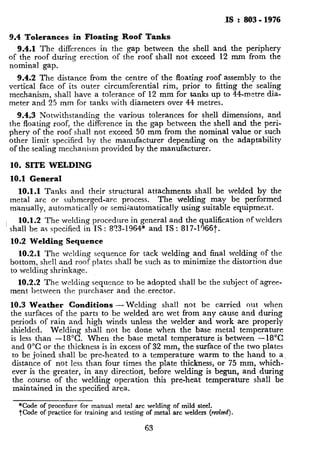

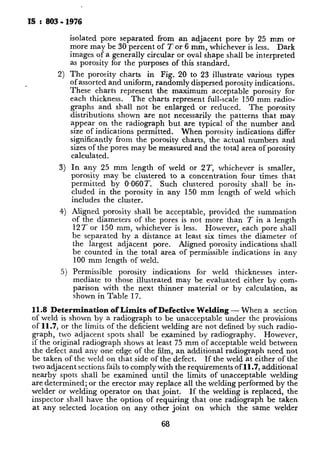

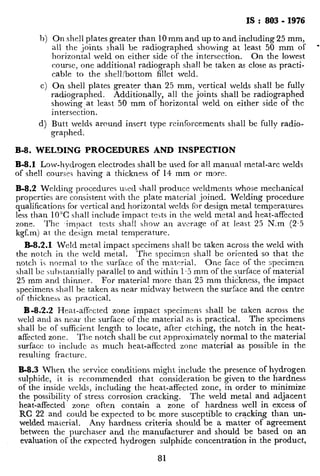

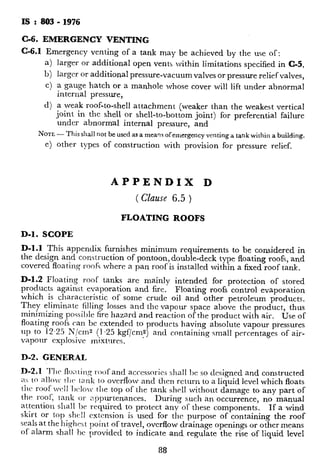

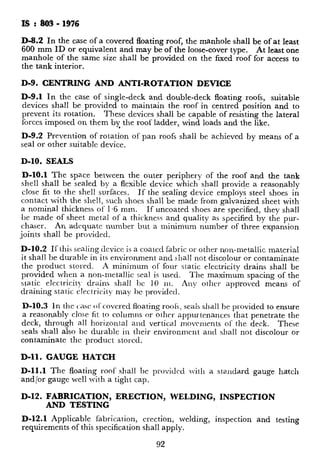

TABLE 18 THERMAL VENTING CAPACITY REQUIREMENTS

(Clauses C-3.3.2 and C-3.4.2)

[Expressed in cubic metres of free air per hour at 10 N/cm% (1 kgf/cms) and 15”C]

TANK CAPACITY VACUUM

(INRI~EATHING)

$3

7.5

;:

120

240

z

600

1 200

1 800

2400

3 000

3 600

4 200

4 800

5 400

6 000

7 200

8 350

9 550

10 750

11 950

(2)

1.75

3

15

z:

18165

145

285

425

570

680

795

880

965

050

::

360

475

590

700

14 300 1 925

16 700 2 125

19 100 2 325

21 500 2 550

PRESSURE(OUTBREATHING)

’ Flash Point

40% or Above

(3)

1.25

1.75

8.5

I7

35

SO

70

187;

255

340

425

485

540

595

655

Flau)r Point

Below 40°C

(4)

1.75

3

:;

60

1;;

285145

425

570

680

795

880

965

1 050

680

765-.

825

880

965

1 020

1 135

1245

1 360

1 475

1 590

1 700

1160 1 925

1275 2 125

1415 2 325

1 53ct 2 550

NOTE- For tanks with intermediate capacities, values may be computed by

interpolation.

TARLE 19 TOTAL RATE OF EMER

EXPOSURE YERSUS

(Clauses C-4.2

‘[Wetted area ZIcrsuscubic metres of free a

WETTED AREA

(1)

m2

2

3

4

5

6

7

8

9

10

12

14

16

18

20

25

30

35

40

50

60

70

80

90

100

120

140

160

180

200

240

280

NOTE -For exposed wetted surface:

C-4-2(b) and G-4.4. For intermediate

ment should be evaluated by interpolat

86](https://image.slidesharecdn.com/is-160425153502/85/Is-803-1976-90-320.jpg)

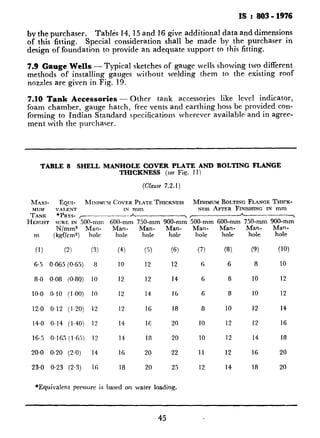

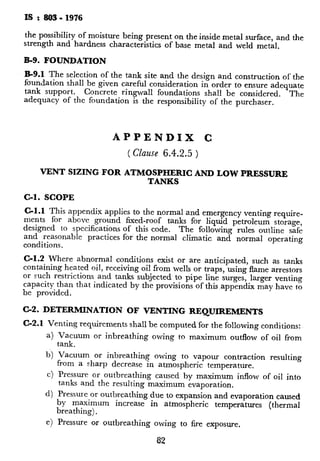

![IS : 803 - 1976

TABLE 19 TOTAL RATE OF EMERGENCY VENTING aEQUIRED FOR FIRE

EXPOSURE VERSUS WETTED SURFACE AREA

(Chses C-4.2, C-4.3 and C-4.5)

.[Wetted area rer$aScubic metres of free air per hour. at 10 N/cm* (1 kgf/cm*) and 15”C]

WETTED AREA

(1)

ma

2

3

4

5

6

7

8

9

10

12

14

16

18

20

25

30

35

40

50

60

70

80

90

100

120

140

160

180

200

240

280

VENTINGREQUIREMENT

(2)

ms/h

600

900

1200

1 500

1 800

2 100

2 400

2 700

3 000

3 600

4 200

4 800

5 400

6 000

6 800

7 500

8 200

8 850

10 000

11 100

12 150

13 100

14 000

14 850

15 800

16656

17 400

18 100

18 750

19 950

21000

NOTE-For exposed wetted surfaces with more than 280 rns area, see C-4.2(a),

C-4-2(b) and C-4.4. For intermediate values of wetted surface area, venting require-

ment should be evalus ted by interpolation.](https://image.slidesharecdn.com/is-160425153502/85/Is-803-1976-91-320.jpg)

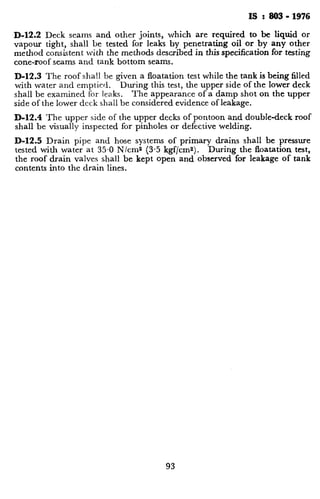

![Addenda

arter 4 2;; 3;. clmre

. . . :

6-4.2+5 ) -- Add the foI!oWing

IlfZW clnuse

‘ 6.4.2.6 Roof‘ plate shall b , ]-C apped with a minimum overlap of 25

shall be lveldcd vith a continuous fillet weld on the top side only

mm and

shall bc arranged ZIS shown in Fig. (A) or (u) of ITig. 7 for roof pl& k$$

deI)rnding on the IocaI conditions by agreement between the purchaser

and the manufacturer.’

6.2.3 Bottom Plate Resting on Piers

6.2.3.1 FOI- tanks erected on an elevated

plate supported on piers or beams, minimur

in mm shall be obtained by the equation:

m11, =

d__I

4,

( PaRe 36, claw 6.4.2.6 )

as 6.4.2.7.

- Renumber the existing clause 6.4.2.6

G =

HI, =

( SMODC 7)

1 zzz

s, 1

2. *Code of practice for use of structural steel in g

specific gravity of stored PI

uniform loading on the bott

due to maximum head of 7

length of bottom plate in CI

successive piers/beams, and

maximum allowable bend

(kgf/cm2).

6.2.3.2 The thickness determined by

shear stresses due to the total load HP X(

shall be increased if required, to keep these

in IS : 800-1962*.

6.2.3.3 Special consideration shall be g

loads acting on the bottom plate.

6.2.3.4 Generally bottom plate built

construction so that the plate rests uniforr

6.2.3.5 ,Rulcs for fabrication given in I

above shall also govern fabrication of the

beams.

6.2.4 The joint between the bottom CC

plate and bottom plate or annular segmcn

fillet weld laid on each side of the shell pl’

be not greater than 12 mm and not less t:

thinner of the two plates joined, nor less

_Vlaximum Thicktless qf‘Shel1

Plate, mm

5

6 to 20

21 to 30

Over 32

Printed PI Dee Kav Printers. NewDelhi. India 21](https://image.slidesharecdn.com/is-160425153502/85/Is-803-1976-99-320.jpg)