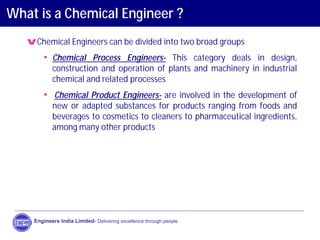

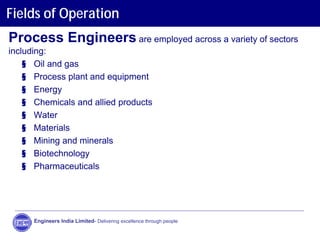

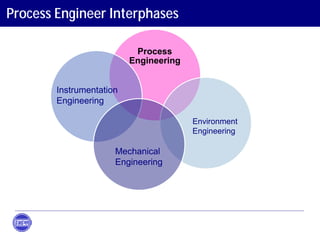

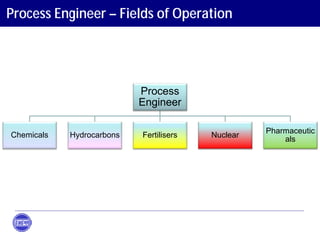

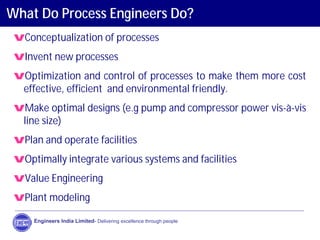

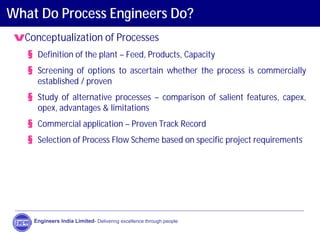

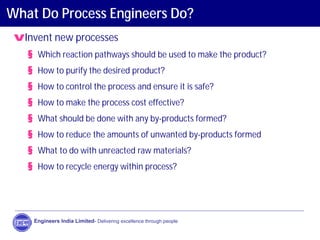

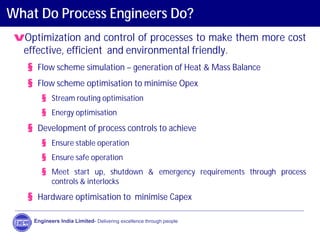

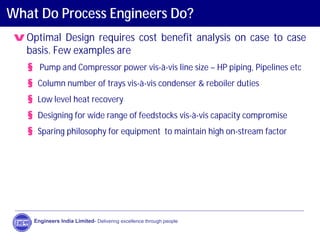

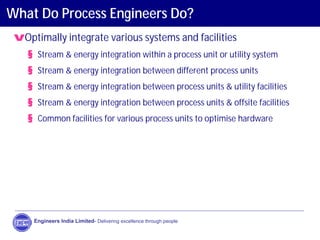

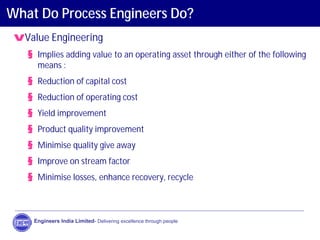

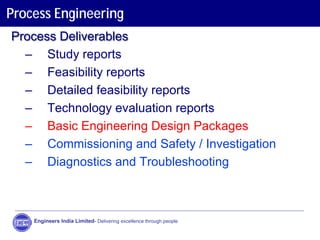

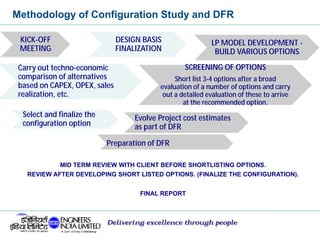

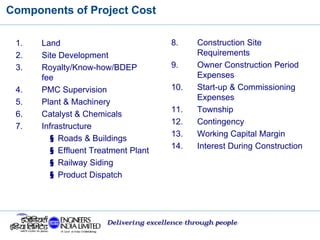

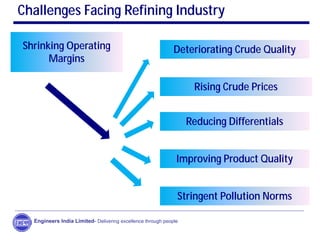

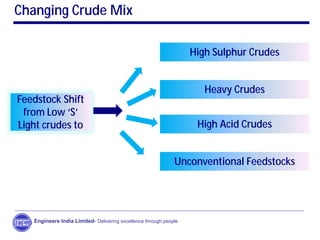

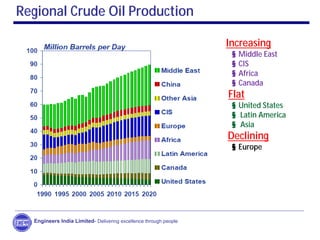

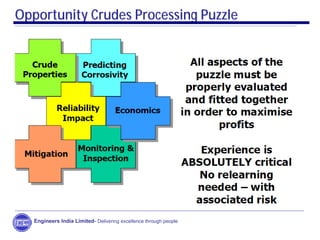

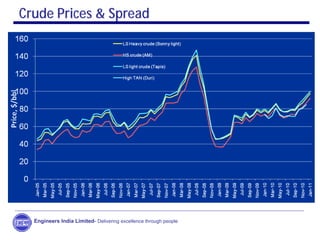

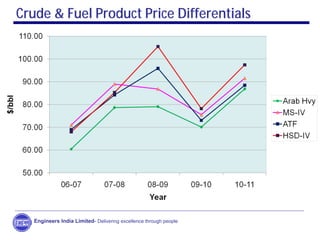

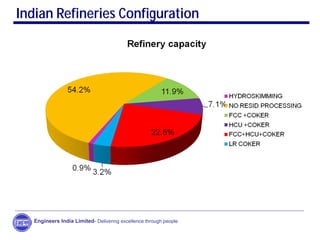

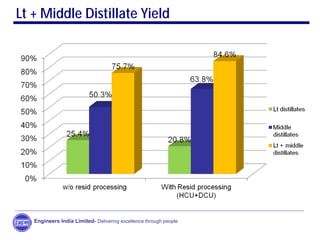

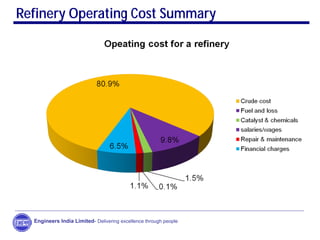

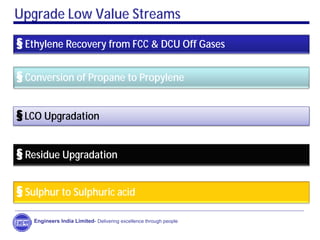

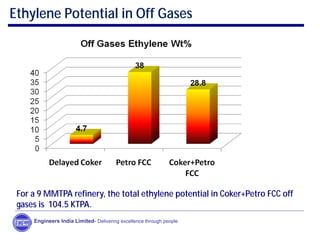

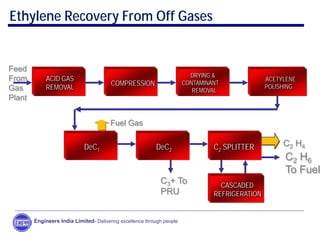

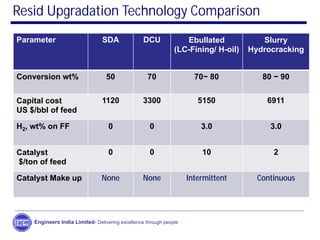

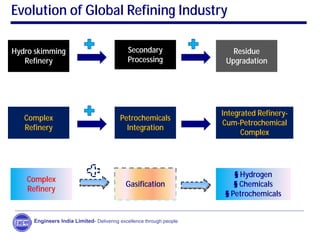

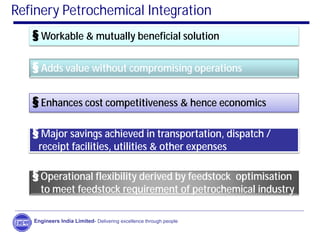

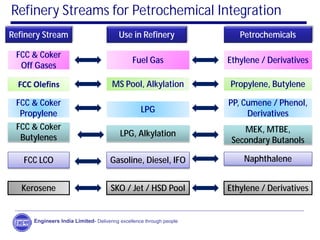

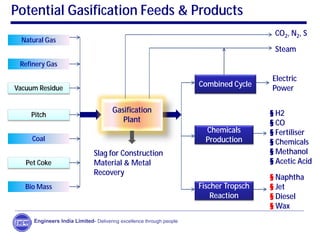

The document provides an overview of process design in chemical engineering, outlining the roles and responsibilities of chemical engineers in various sectors such as oil, gas, and pharmaceuticals. It details the challenges facing the refining industry, including rising crude prices and stringent pollution norms, while emphasizing the importance of innovative processing technologies and integration with petrochemical production. Additionally, the document discusses methodologies for enhancing refinery operations and optimizing costs through advanced engineering practices.