The document details the structural design calculations for a base plate and anchor system for a lattice tower leg, focusing on axial loads, shear, and reinforcement specifics. It includes various equations and required parameters for optimizing base plate dimensions, checking welds, and ensuring compliance with relevant ACI and AISC guidelines. The summarized results indicate that thickness and welding checks passed, while the breakout cone check failed, necessitating additional design considerations.

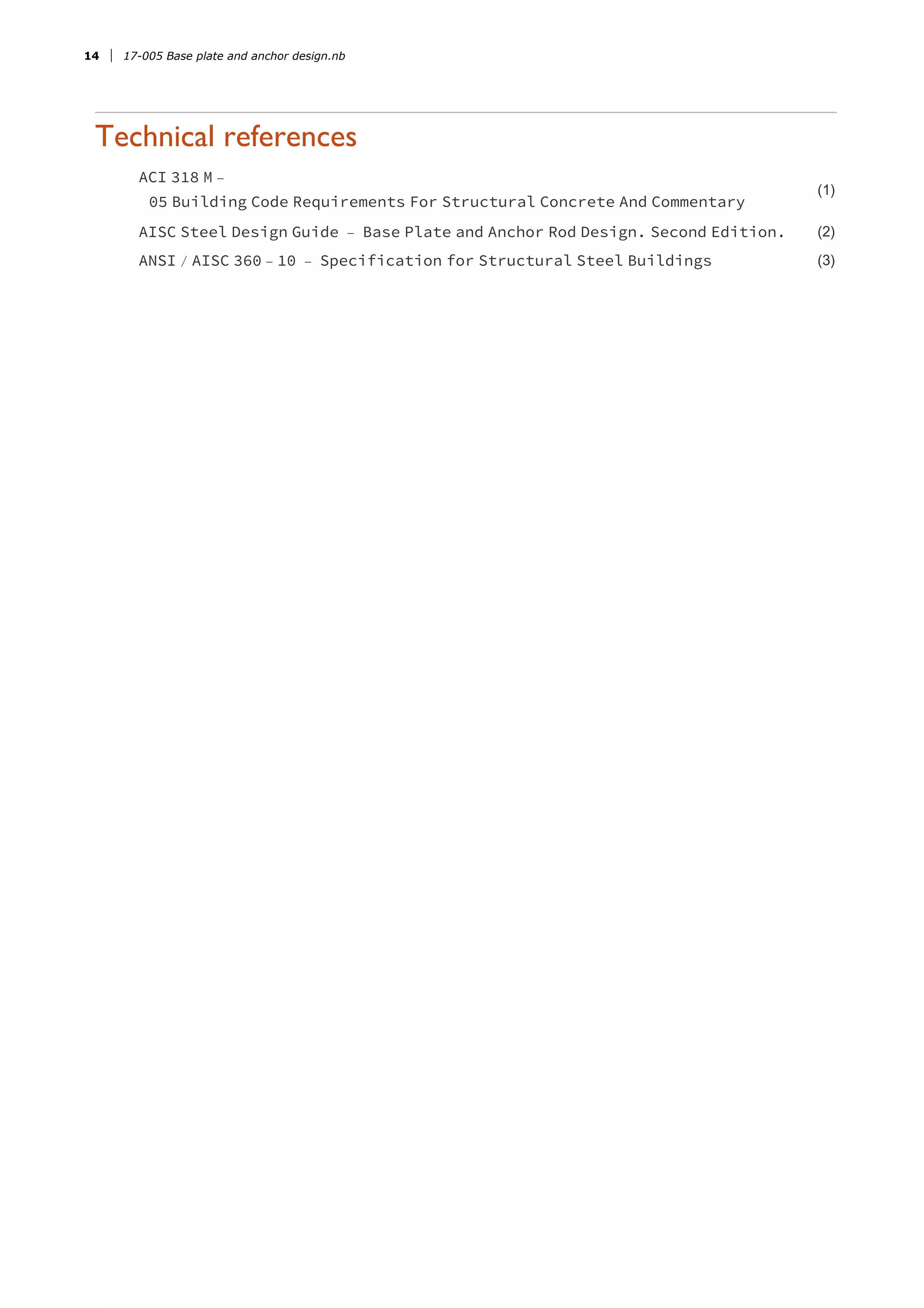

![Modification factor for edge effects in tension

;

ca,min = {266} mm;

Since the anchors are located less than 1.5 hef from three or more edges, the value of hef as per

below

smax = {142} mm;

ca,max = {333} mm;

hef = Max /@ Transposeca,max / 1.5, ca,min

1

3

mm mm

{222. mm}

Concrete brakeout cone area for group

ANc = {600 mm}^2

360 000 mm2

Concrete brakeout cone area for a single anchor

ANco = 9 * hef ^2

443 556. mm2

feDn[x_] := IfThreadca,min / mm < 1.5 hef mm, 0.7 + 0.3

ca,min

1.5 hef

, 1

ψedN = feDn /@ 0.7 + 0.3

ca,min

1.5 hef

{0.93964}

Cracking factor, assumed that the region of analysis where the anchors are placed is cracked

ψcN = 1.0;

Modification factor for post-installed anchors.

17-005 Base plate and anchor design.nb ���9](https://image.slidesharecdn.com/17-005baseplateandanchordesign-180227152344/75/Base-plate-and-anchor-design-9-2048.jpg)

![�������

The following are the summarized results for all the checks above

num = 1;

thCheckFormatted = Table[If[StringMatchQ[thCheck[[i]], "PASS"],

Style[thCheck[[i]], Green], Style[thCheck[[i]], Red]], {i, 1, num}]

{PASS}

weldCheckFormatted = Table[If[StringMatchQ[weldCheck[[i]], "PASS"],

Style[weldCheck[[i]], Green], Style[weldCheck[[i]], Red]], {i, 1, num}]

{PASS}

brkOutCheckFormatted =

Table[If[TrueQ[brkOutCheck[[i]]], Style[brkOutCheck[[i]], Green],

Style[brkOutCheck[[i]], Gray, Italic]], {i, 1, num}]

{False}

devLengthCheckFormatted =

Table[If[StringMatchQ[devLengthCheck[[i]], "PASS"], Style[

devLengthCheck[[i]], Green], Style[devLengthCheck[[i]], Red]], {i, 1, num}]

������������� ������ �� ���� �� ������� �������� �� �������� � �� ������������[������ ����]�

{If[StringMatchQ[False, PASS],

Style[devLengthCheck〚i〛, Green], Style[devLengthCheck〚i〛, Red]]}

sum = TableForm[

{bf, Pu, Pt, Wprov, tprov, ca,min, ca,max, smax, ANc, nre, dre1, thCheckFormatted,

weldCheckFormatted, brkOutCheckFormatted, devLengthCheckFormatted},

TableHeadings → {{"Main leg size", "Compression",

"Tension", "Base plate size", "Base plate thickness",

"anchor min. edge distance", "anchor max. edge distance",

"max. anchor distance", "Column size", "No. of vertical rebars",

"Diameter of reinforcement", "Thickness check", "Welding check",

"Brakeout cone check", "Developement length check"}, myTowers}]

12��� 17-005 Base plate and anchor design.nb](https://image.slidesharecdn.com/17-005baseplateandanchordesign-180227152344/75/Base-plate-and-anchor-design-12-2048.jpg)

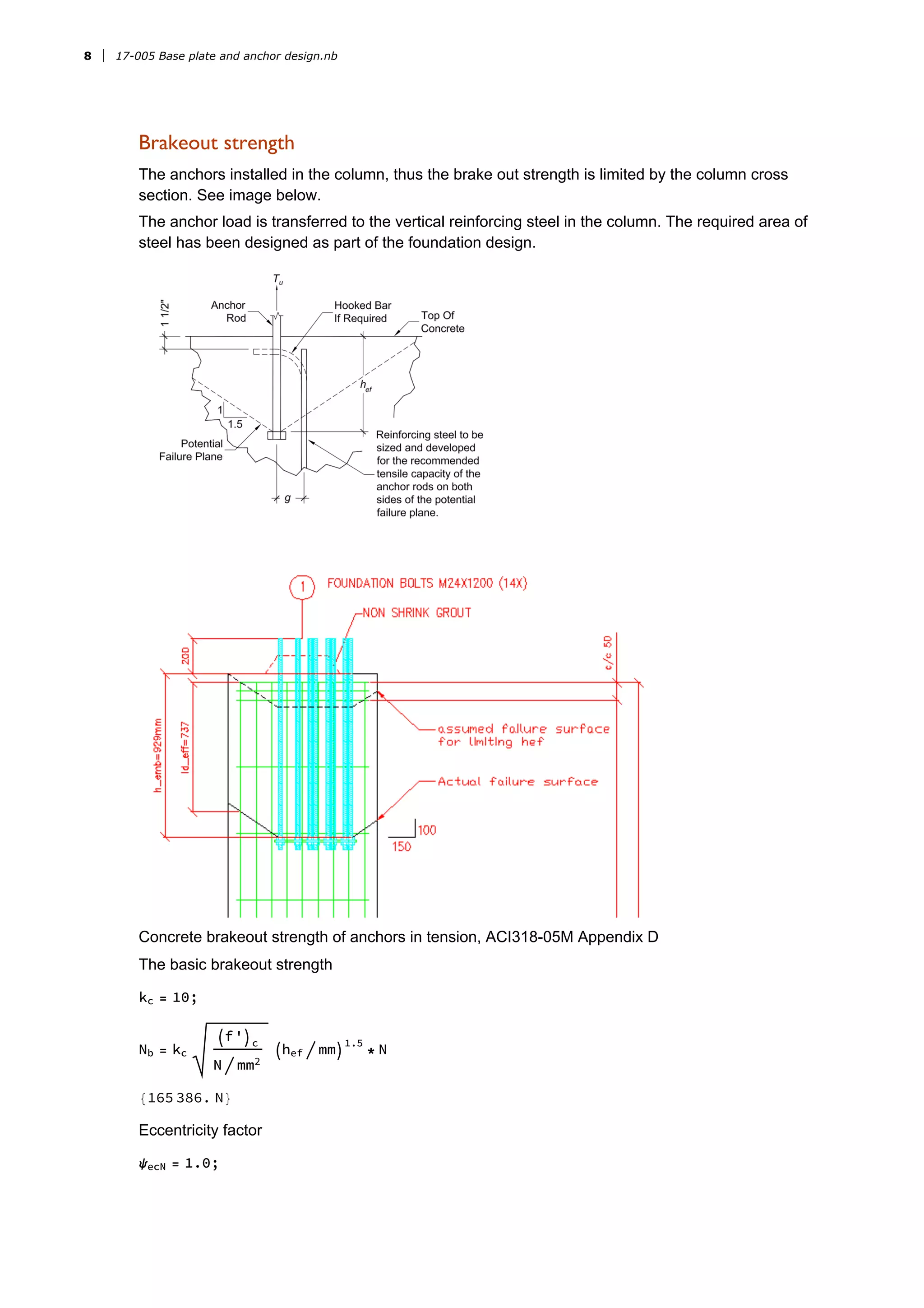

![RTB15m

Main leg size 100 mm

Compression 333 000 N

Tension 315 000 N

Base plate size 400 mm

Base plate thickness 30 mm

anchor min. edge distance 266 mm

anchor max. edge distance 333 mm

max. anchor distance 142 mm

Column size 360 000 mm2

No. of vertical rebars 12

Diameter of reinforcement 12 mm

Thickness check PASS

Welding check PASS

Brakeout cone check False

Developement length check If[StringMatchQ[False, PASS], Style[devLengthCheck〚i〛

17-005 Base plate and anchor design.nb ���13](https://image.slidesharecdn.com/17-005baseplateandanchordesign-180227152344/75/Base-plate-and-anchor-design-13-2048.jpg)