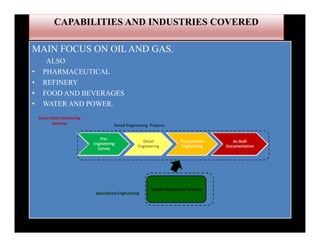

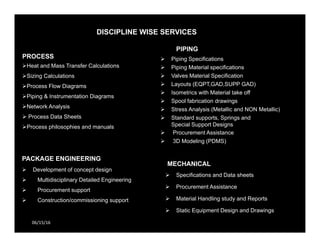

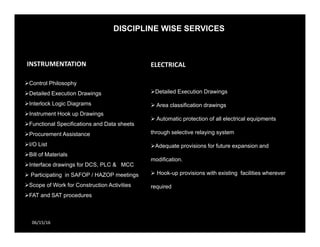

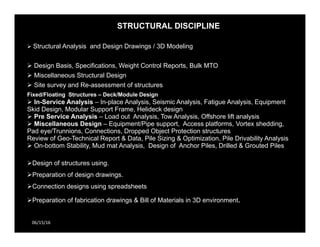

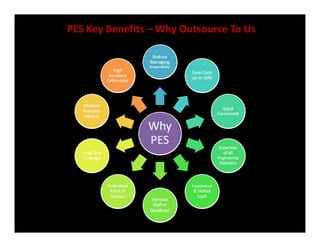

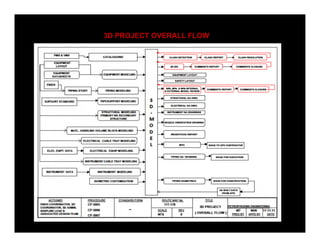

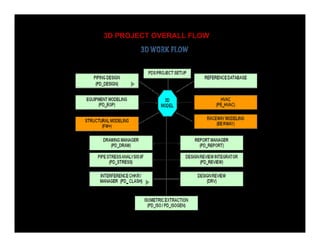

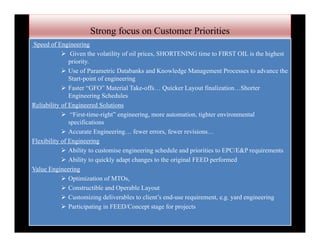

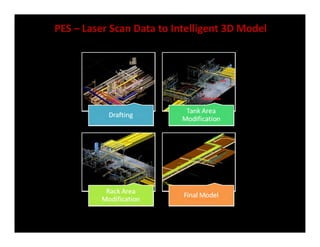

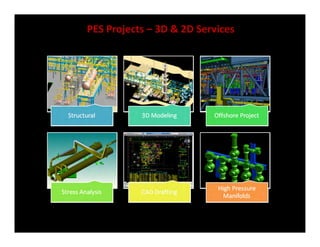

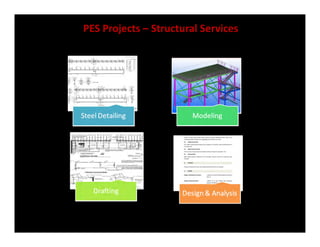

This document provides an overview of PetroPhoenix Engineering Solutions Pvt Ltd, an engineering consultancy firm. It outlines the company's vision, mission, goals and capabilities in various engineering disciplines such as process, piping, instrumentation, electrical, and structural engineering. The company focuses on industries like oil and gas, pharmaceuticals, refinery and power. It details the engineering services offered, software expertise, quality processes, 3D modeling capabilities, and provides some sample drawings. The document emphasizes customer priorities, project execution, safety, reliability and change management.