This document discusses quality assurance in mycobacteriology laboratories. It describes the three main components of a quality assurance system as quality control, external quality assessment, and quality improvement. Quality control procedures should address pre-analytical, analytical, and post-analytical phases of testing. Monitoring performance indicators such as contamination rates, turnaround times, and proficiency testing scores helps to evaluate laboratory performance and identify areas for improvement.

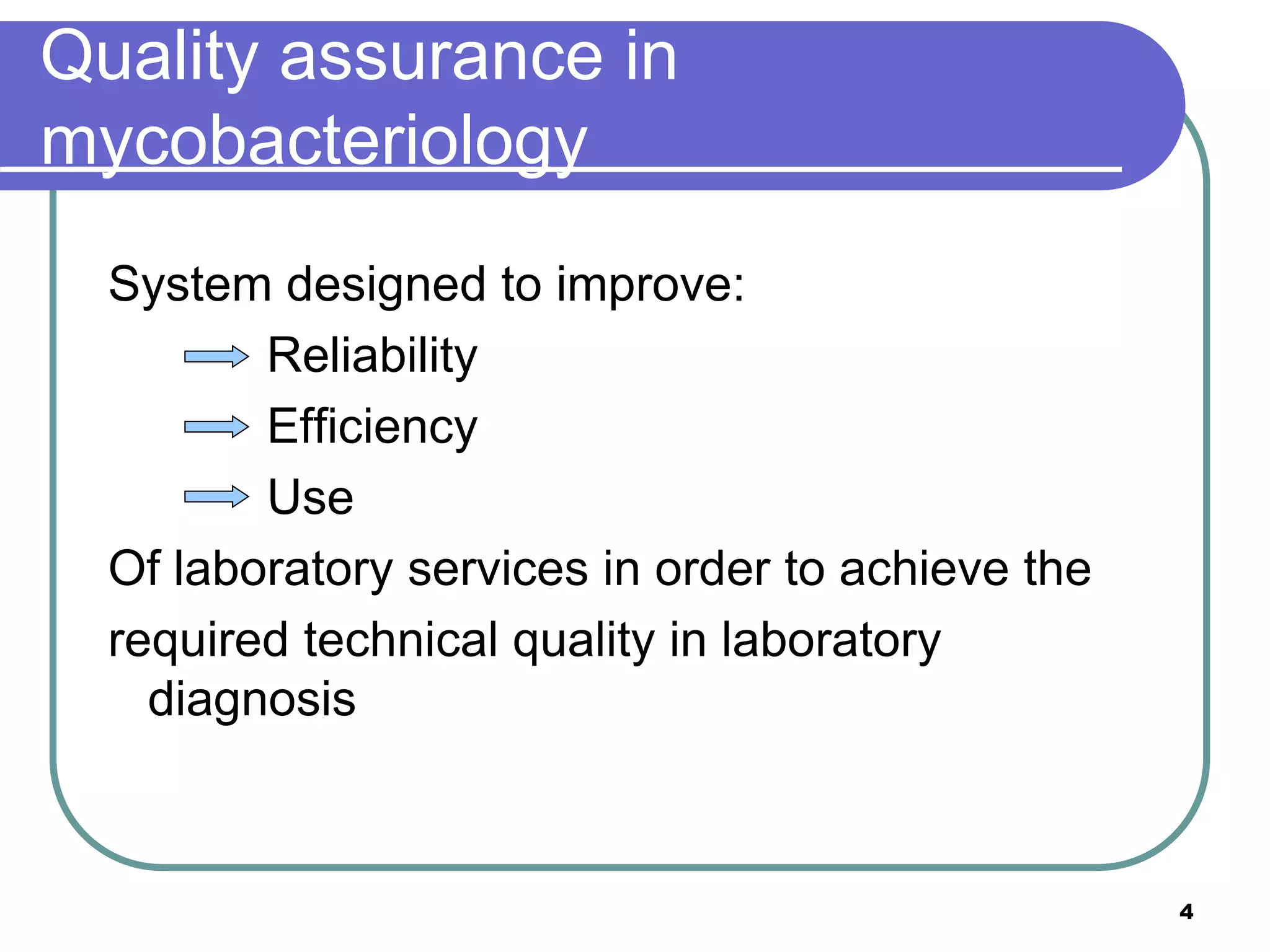

![Corrective actions: example

Identify (potential) problem: suboptimal or poor quality media [LJ]

Analyze the (potential) problem: poor quality media may impact the

yield/recovery of MTBC, lack of media may impact turn around time

Identify the (potential) solution: potential solutions include

purchasing commercially prepared media, or asking for assistance

from the NRL

Select and plan solution: gather catalog and vendor information or

contact NRL to establish relationship and determine the feasibility of

this option

Implement solution

Evaluate solution: determine the cost effectiveness of the solution,

the amount of lead time required to receive the media

Maintain and/or improve solution

Reference: Corrective and preventive action document. SANAS (South African

National Accreditation System)

18](https://image.slidesharecdn.com/qualityassurancequalindicators-230214063040-9523c2b5/75/Quality-Assurance-Qual-Indicators-ppt-18-2048.jpg)