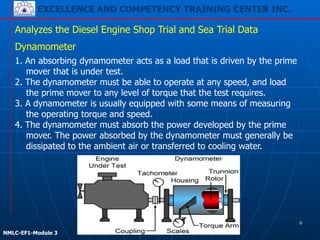

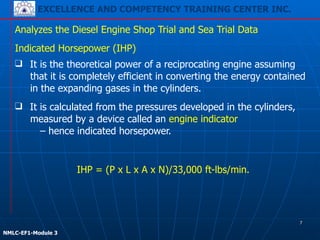

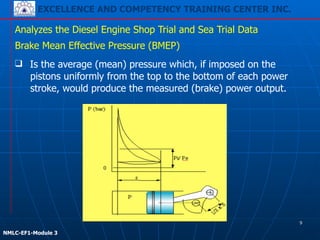

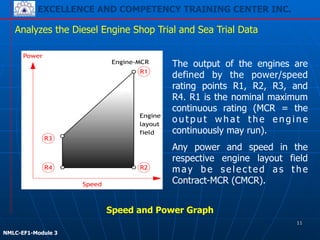

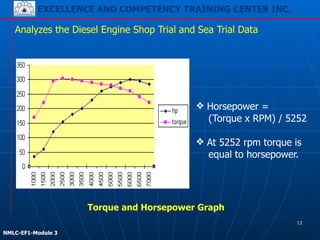

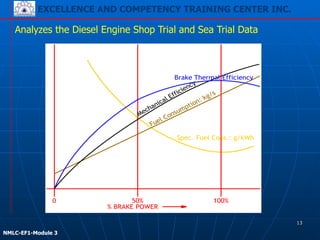

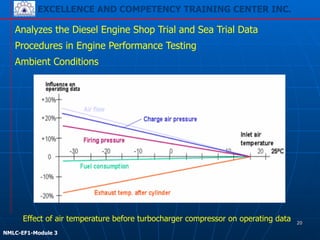

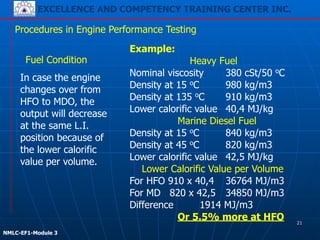

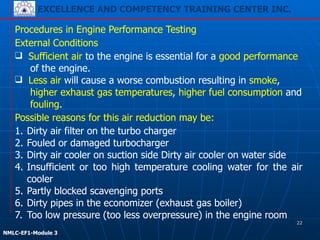

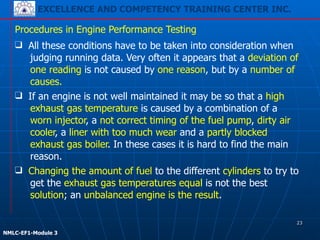

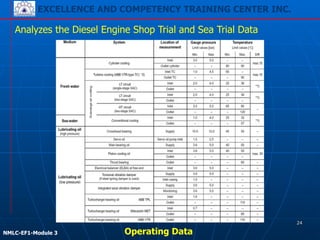

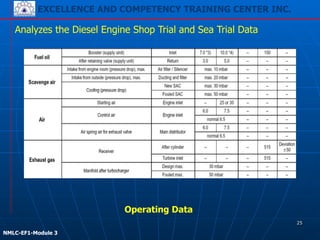

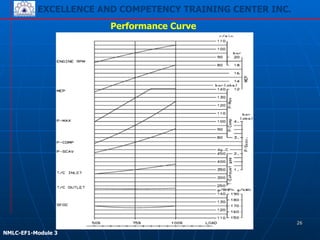

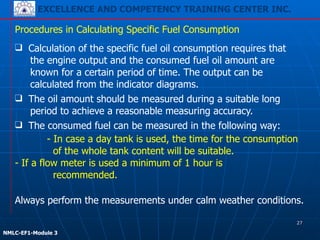

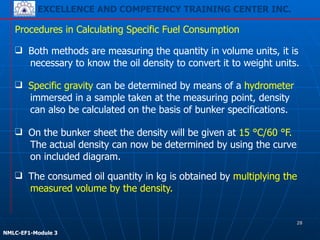

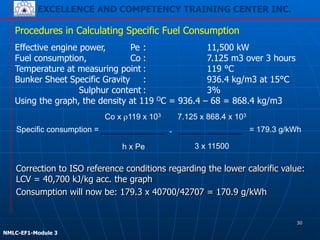

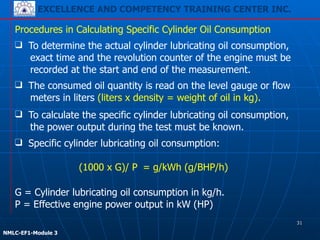

The document discusses modules for marine engineering at the management level provided by Excellence and Competency Training Center Inc. It covers operating principles of ship power installations, analyzing diesel engine shop trial and sea trial data, procedures for engine performance testing and calculating specific fuel consumption. Key concepts discussed include indicated horsepower, brake horsepower, mechanical efficiency, thermal efficiency, fuel consumption, and the effects of ambient conditions on engine performance.