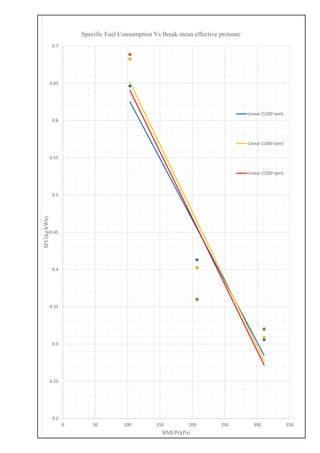

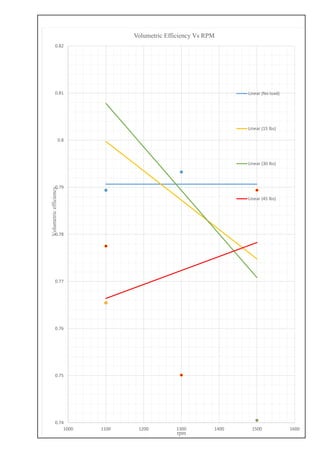

This document summarizes an experiment conducted on a Perkins diesel engine to measure various parameters. The experiment measured the brake power, indicated power, thermal efficiency, volumetric efficiency, mean effective pressure, specific fuel consumption and swept volume of the engine at different loads and RPMs. Calculations were shown for measurements taken at 1100 RPM with a 30 lbs load. Graphs were presented comparing fuel consumption to brake power and specific fuel consumption to brake mean effective pressure. Results tables displayed the various parameters measured across different loads and RPMs. The discussion section described common applications of compression ignition engines and their advantages.