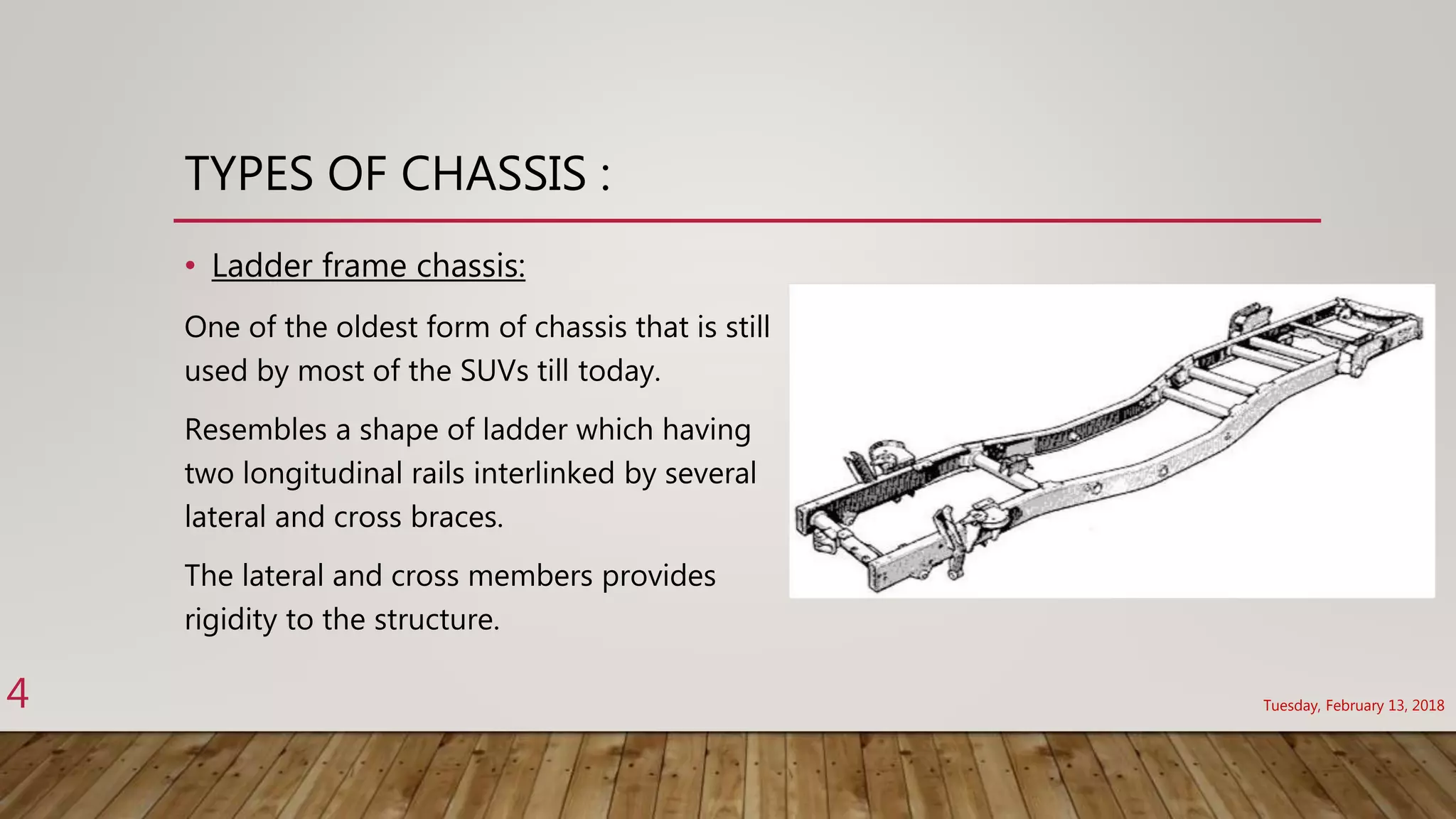

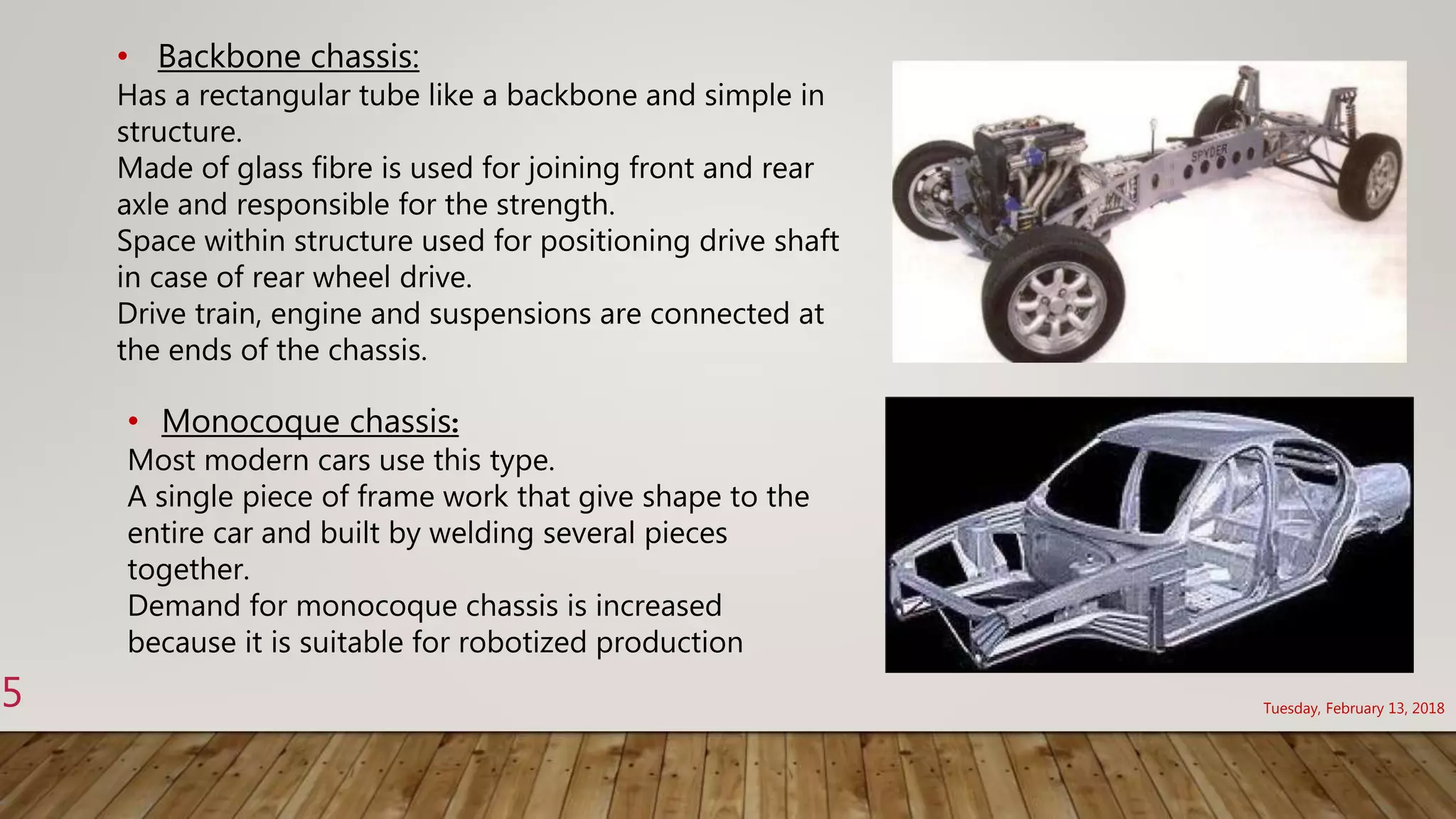

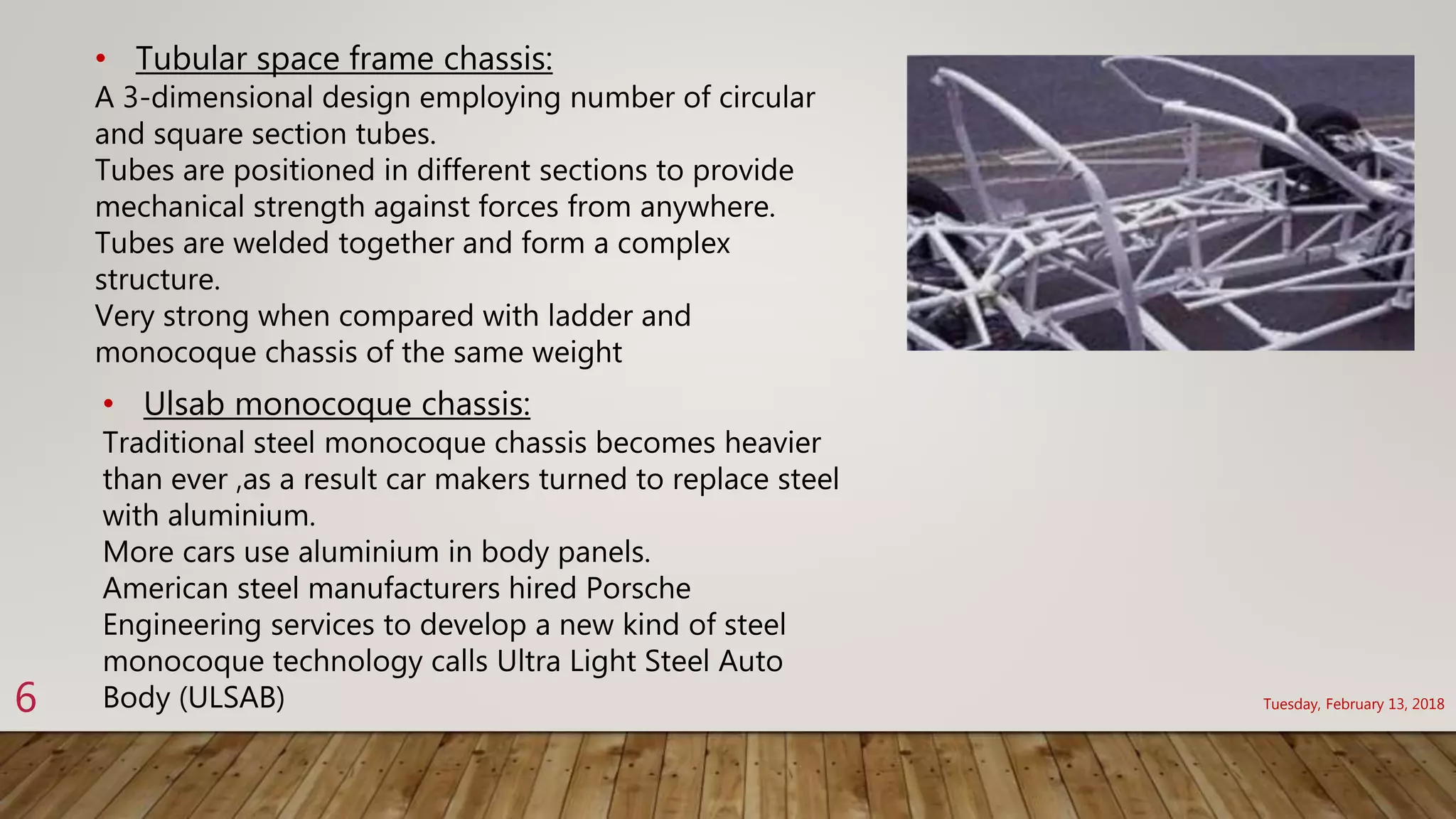

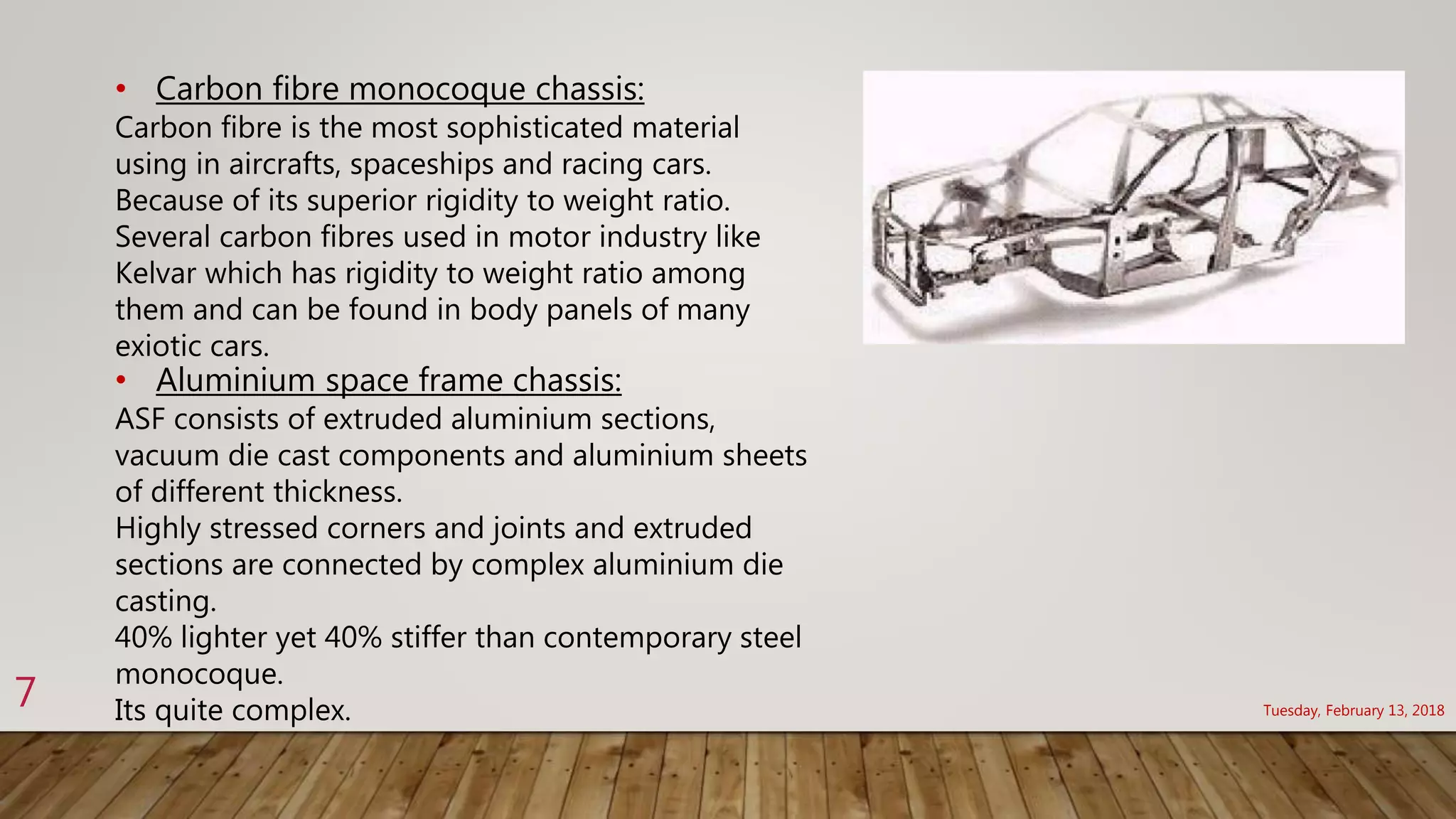

This document presents design considerations for vehicle chassis, detailing their functions, types, and general requirements. It describes various chassis types including ladder frame, monocoque, and carbon fiber, each with unique structural characteristics and applications. The document also outlines general considerations for chassis design such as weight, space, manufacturability, and load resistance.