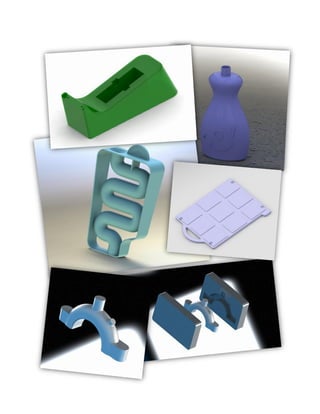

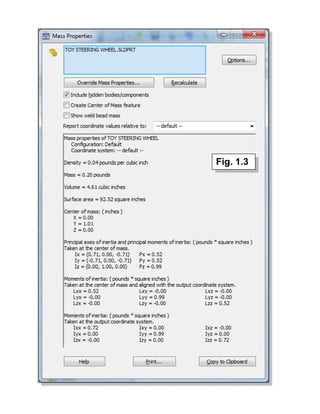

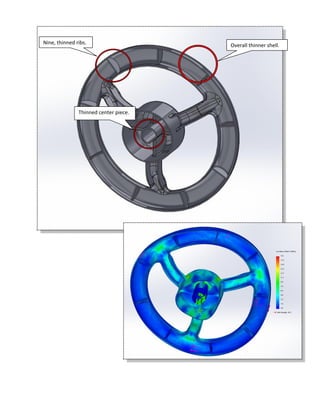

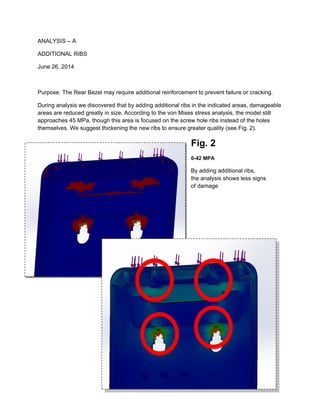

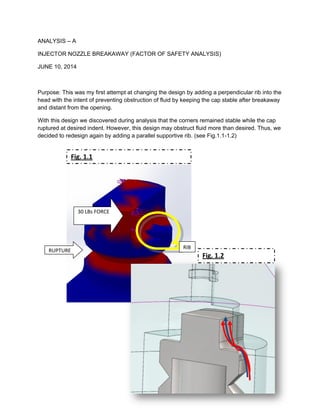

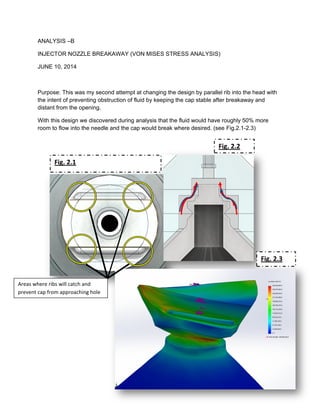

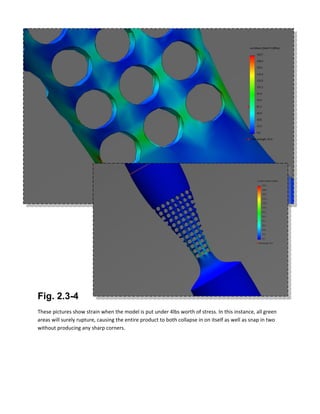

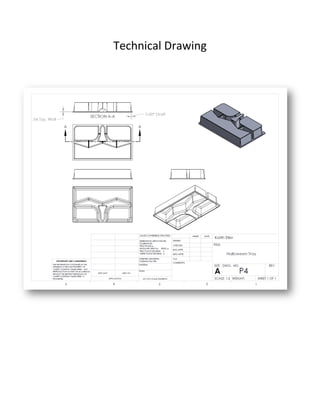

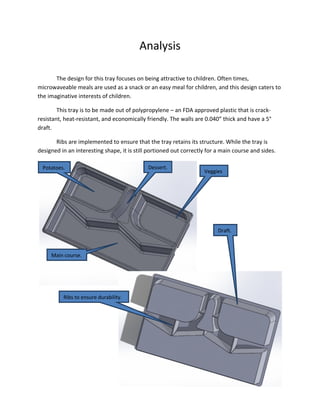

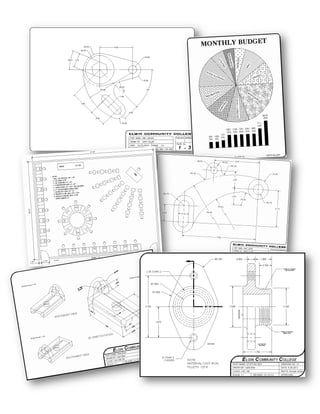

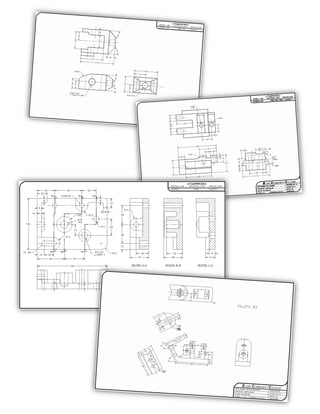

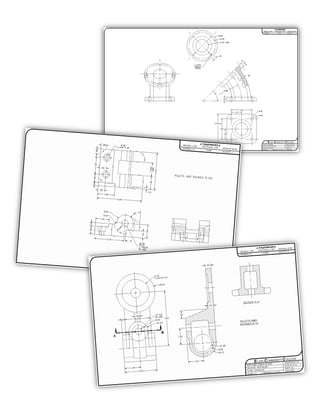

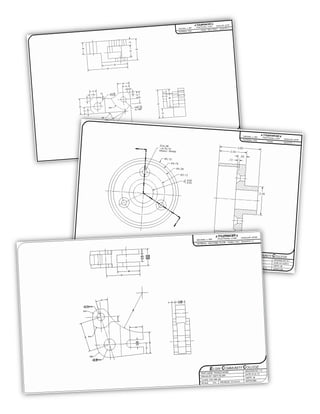

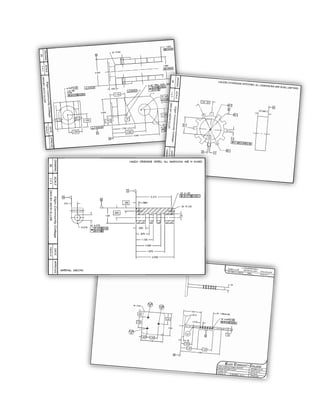

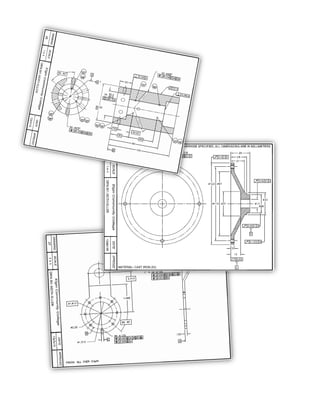

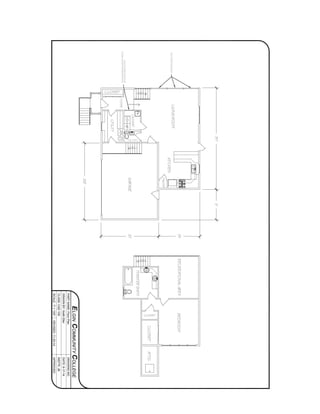

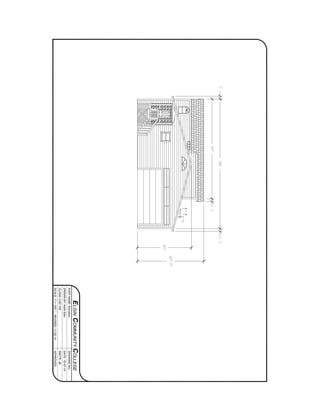

These parts were created using SolidWorks and required focus and patience. Both basic and advanced SolidWorks skills were used. Finite element analysis was performed on several parts to analyze stress, strain, heat dispersion, and fluid flow. Parts were redesigned to improve efficiency and cost-effectiveness based on the analysis results.