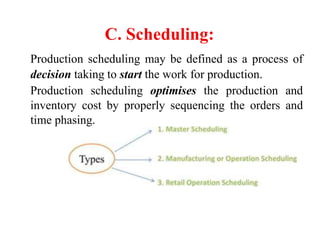

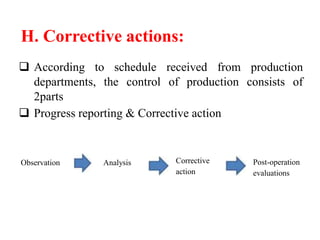

The document discusses production planning and control, emphasizing the need for efficient and economical production through careful planning, routing, scheduling, and dispatching. It outlines the objectives, processes, and techniques involved in manufacturing, including the importance of inspection and corrective actions. Limitations of production planning and control, such as lack of reliable data and external factors, are also highlighted.