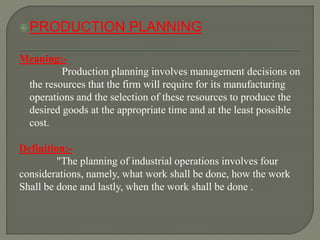

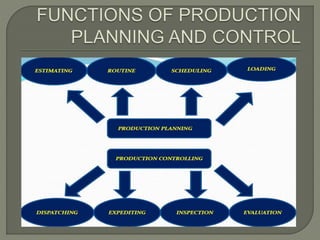

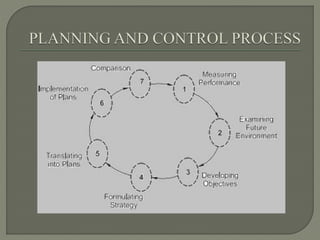

1. Production planning and control involves coordinating all functions of the manufacturing process from procuring materials to shipping finished goods according to a plan to efficiently use plant facilities.

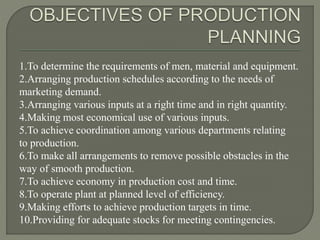

2. It determines requirements for materials, equipment, and labor and arranges production schedules according to marketing demand while efficiently using all inputs.

3. The goal is to achieve coordination across departments, remove obstacles to smooth production, and operate plants at planned efficiency levels to meet production targets on time.

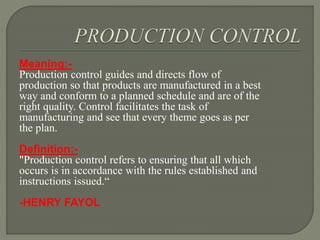

![1.It maintains good coordination between the departments.

2. It reduces the employee and plant idle time.

3. It ensures the optimum utilization of resources.

4. It helps in achieving the quality standards so that the quality of

output is ensured.

5. It minimize the wastes, scrap, rework and also the rectification

hour.

6. It also helps in utilizing idle time of the machine.

7. It make sures the availability of right supplies at right time

[inventory control].

8. It avoids bottlenecks in the production process.

9. It ensures better services to customers by delivering quality

goods within the specified time period.](https://image.slidesharecdn.com/presentation1-180302052018/85/PRODUCTION-PLANNING-AND-CONTROL-9-320.jpg)