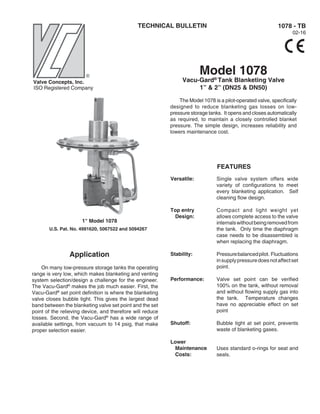

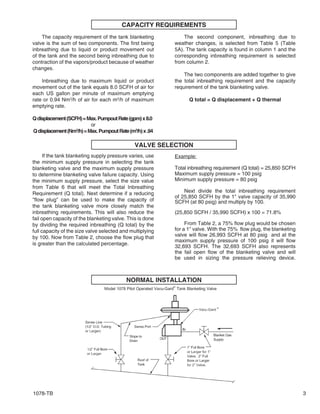

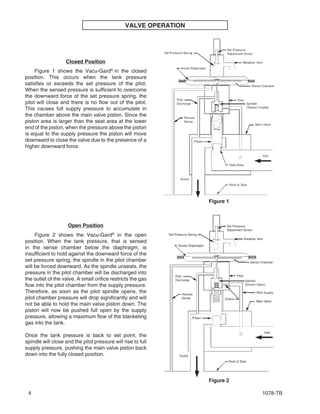

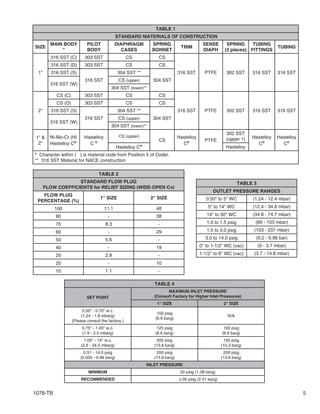

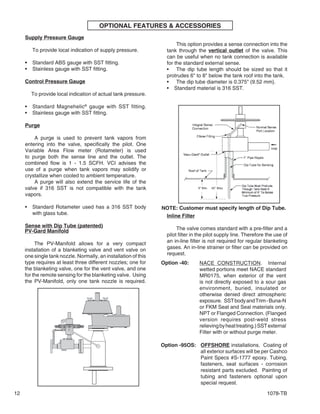

The Model 1078 Vacu-Gard® tank blanketing valve is a pilot-operated valve designed to minimize gas losses in low-pressure storage tanks by maintaining controlled blanket pressure through automatic opening and closing. It features a simple design for increased reliability and lower maintenance costs, with a variety of configurations and settings that accommodate different tank applications. Key materials and temperature limits are specified, along with capacity requirements for effective operation under varying supply pressures.