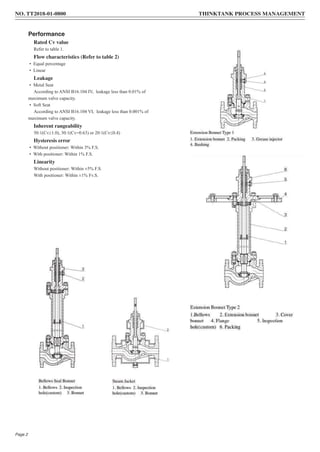

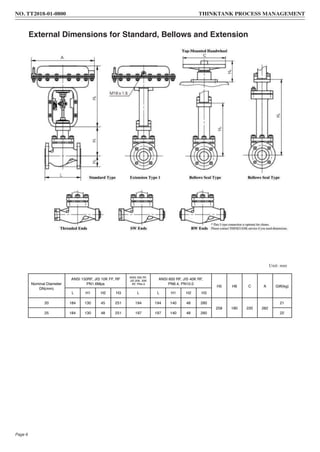

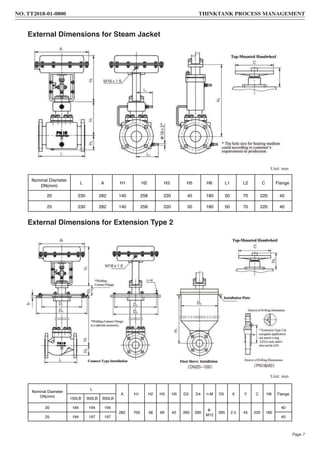

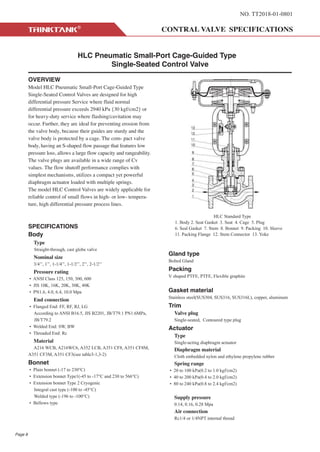

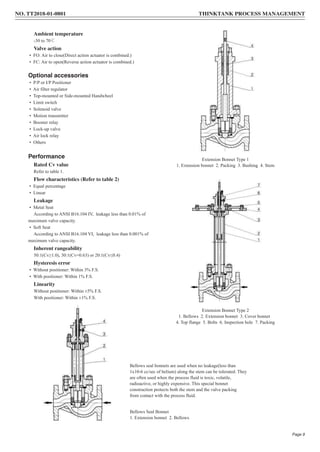

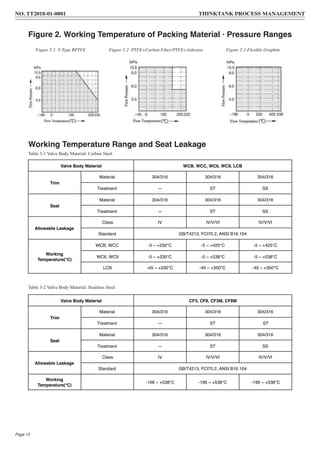

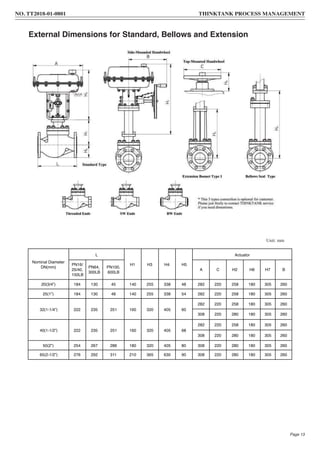

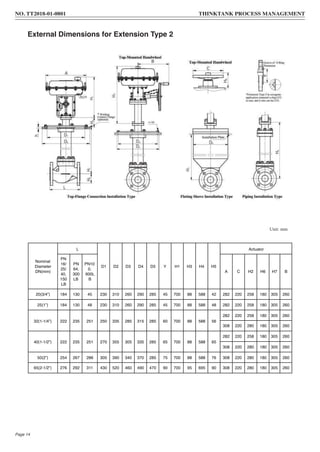

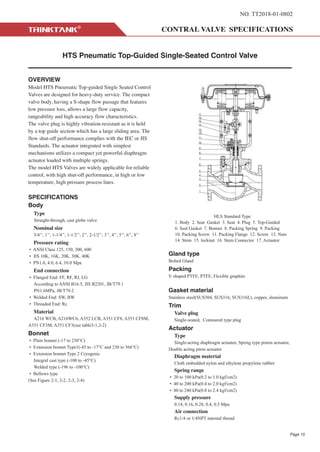

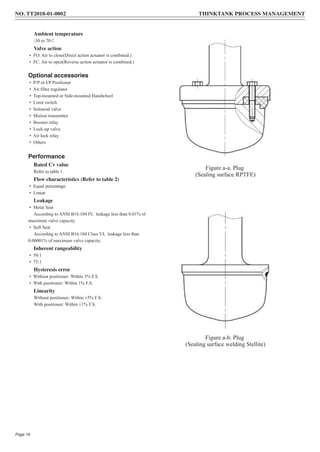

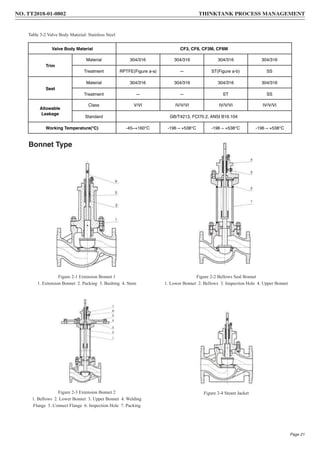

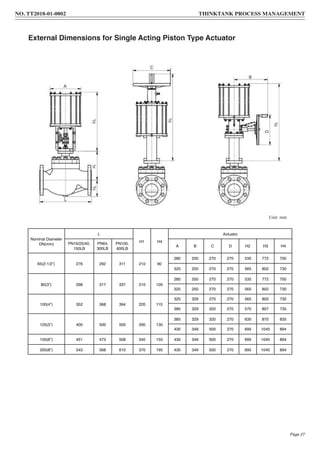

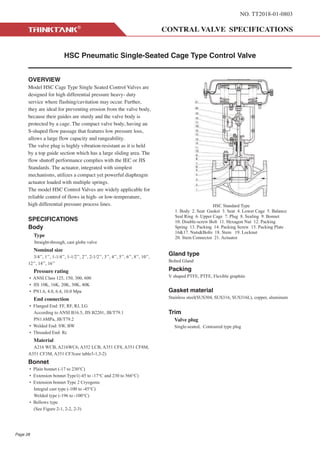

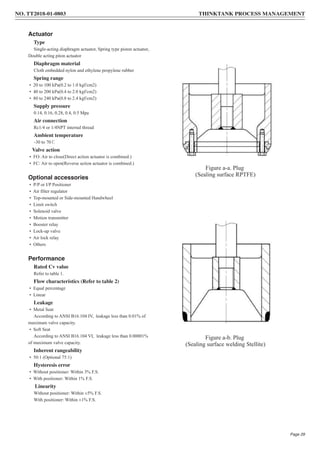

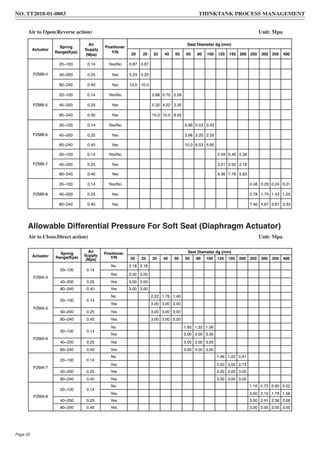

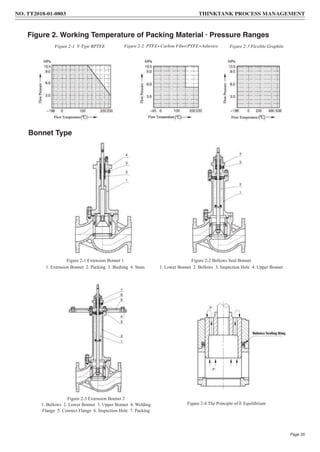

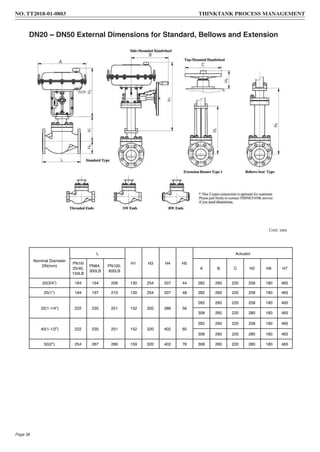

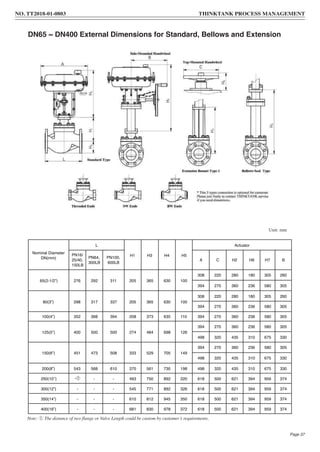

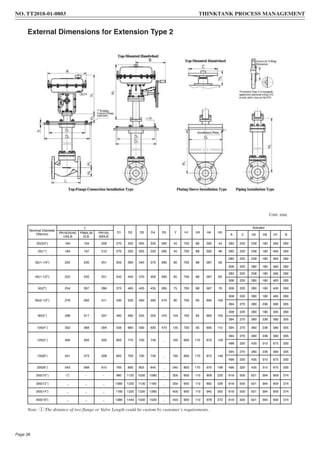

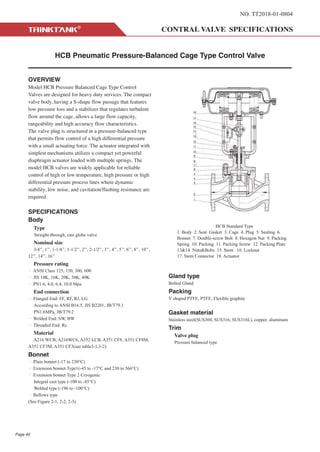

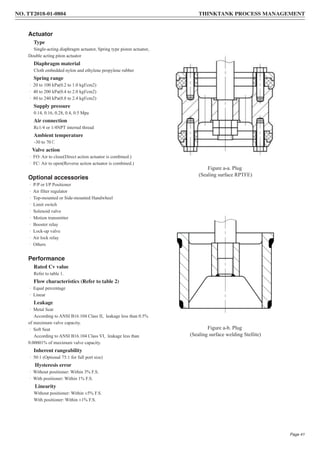

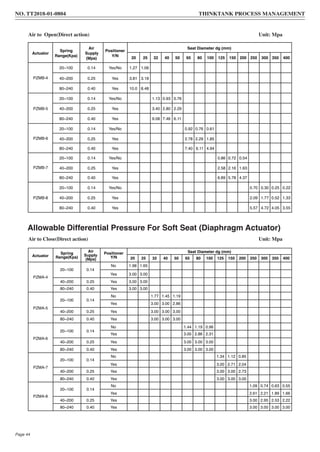

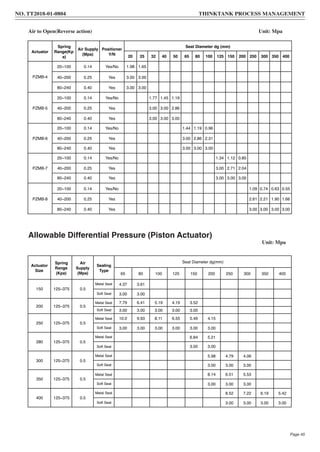

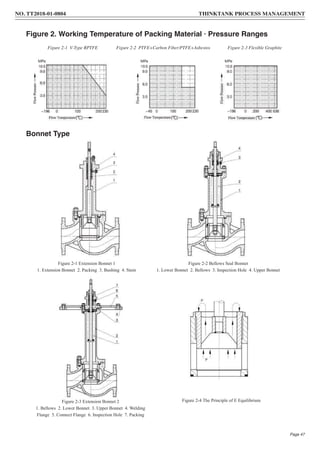

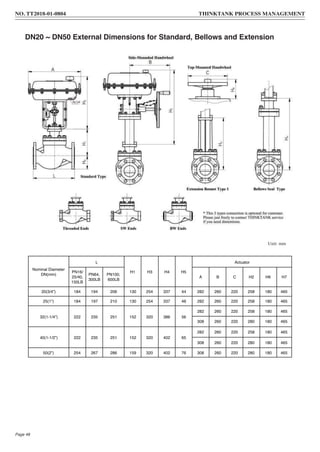

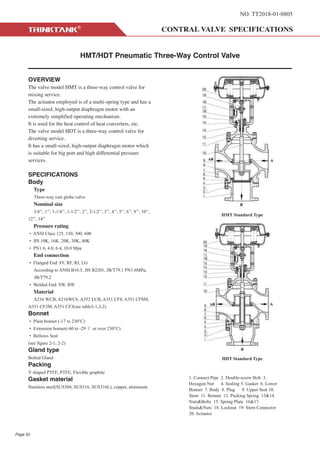

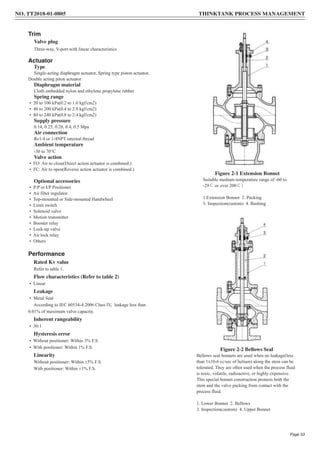

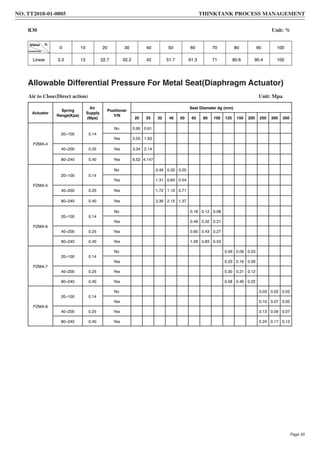

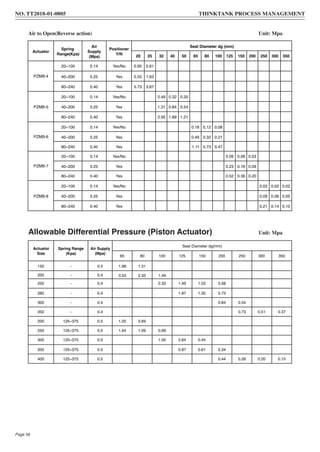

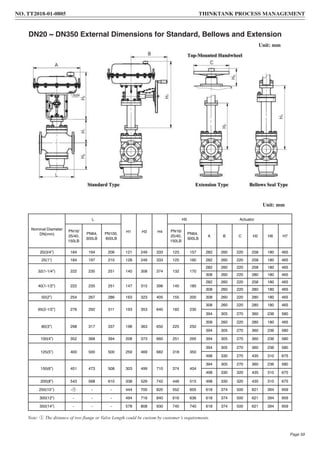

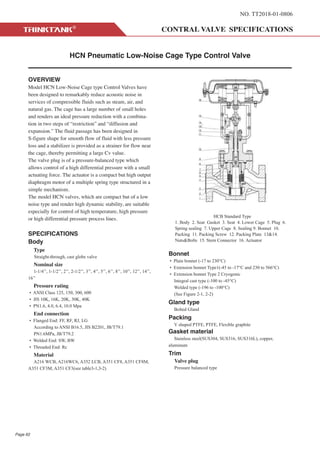

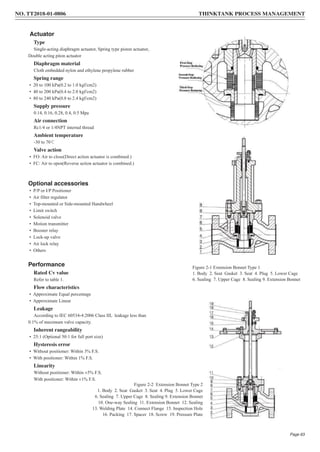

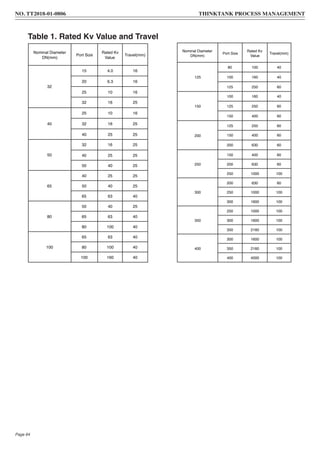

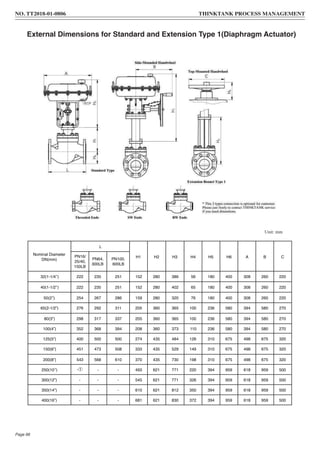

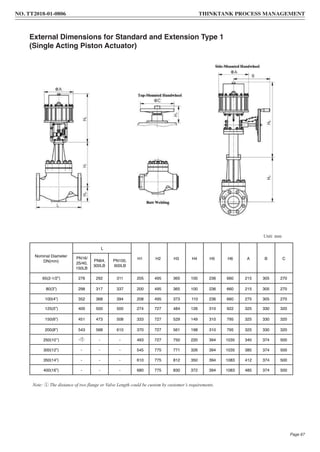

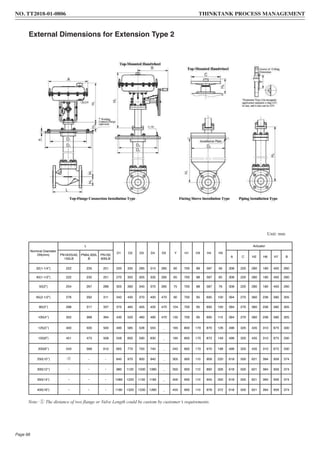

The document is a product manual for the HLS pneumatic small-port single-seated control valve, detailing its design specifications, features, and performance characteristics. The valve is compact yet powerful, suitable for heavy-duty service with low pressure loss and high accuracy flow. Various optional accessories and materials are available for customization according to operational needs.