This presentation covers pressure relief devices, specifically safety valves, their definitions, types, design options, classifications, legal aspects, and maintenance. It outlines the causes of excess pressure, various loading principles, and applicable regulations from organizations like ASME, API, and ISO. The document also addresses installation applications, general issues, and best practices to ensure safety and compliance.

![10/10/2017

7

13

Meet- en Regeltechniek

Classification-Definition Safety Valves-AD2000-A2

Performance / Opening Characteristics

Opening Characteristics

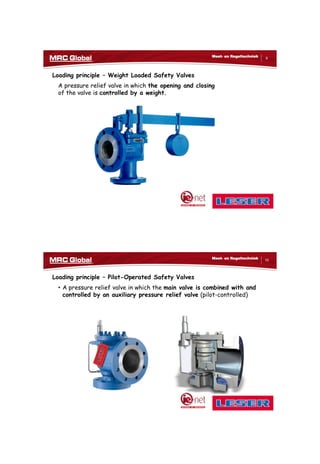

o Normal Safety Valve Pursuant to AD 2000 Information Sheet A2

A spring loaded pressure relief valve actuated by the static pressure upstream of

the valve. The valve opens in proportion to the pressure increase over the opening

pressure. Used primarily with liquid service (non-compressible).

100

80

60

40

20

0

Lift [%]

pc

p = set pressure pc = opening pressure

pp = popping pressure ps = closing pressure

90 100 110

ps

p

Pressure [%]

pp

14

Meet- en Regeltechniek

Classification-Definition Safety Valves-AD2000-A2

Performance / Opening Characteristics

Opening Characteristics

o Normal Safety Valve Pursuant to AD 2000 Information Sheet A2

A spring-loaded normal safety valve opening proportionately or suddenly within a

pressure increase of 10%.

Used with all media: steam, vapour, gas and liquids.

100

80

60

40

20

0

Lift [%]

pc

p = set pressure pc = opening pressure

pp = popping pressure ps = closing pressure

ps

p

Pressure [%]

pp

80 90 100 105 110 120

Standard 10% - Pop-Acting](https://image.slidesharecdn.com/ienetpresentationmrcglobalmdj-171018103727/85/Pressure-Relief-Devices-7-320.jpg)

![10/10/2017

8

15

Meet- en Regeltechniek

Classification-Definition Safety Valves-AD2000-A2

Performance / Opening Characteristics

Opening Characteristics

o Full-lift Safety Valve Pursuant to AD 2000 Information Sheet A2

A spring-loaded full-lift safety valve opening suddenly within a pressure increase of

5%. Primarily used for gas, steam and vapour

100

80

60

40

20

0

Lift [%]

pc

p = set pressure pc = opening pressure

pp = popping pressure ps = closing pressure

ps

p

Pressure [%]

pp

80 90 100 105 110 120

Sudden opening within 5%

16

Meet- en Regeltechniek

Classification-Definition Safety Valves-ASME PTC 25-2014

Performance / Opening Characteristics

Relief valve

o A pressure relief valve characterized by gradual opening that is generally

proportional to the increase in pressure. It is normally used for incompressible

fluids.

Safety relief valve

o A pressure relief valve characterized by rapid opening or by gradual opening that

is generally proportional to the increase in pressure. It can be used for

compressible or incompressible fluids.

Safety valve

o A pressure relief valve characterized by rapid opening and normally used to

relieve compressible fluids.

Prssure [%]](https://image.slidesharecdn.com/ienetpresentationmrcglobalmdj-171018103727/85/Pressure-Relief-Devices-8-320.jpg)

![10/10/2017

26

51

Meet- en Regeltechniek

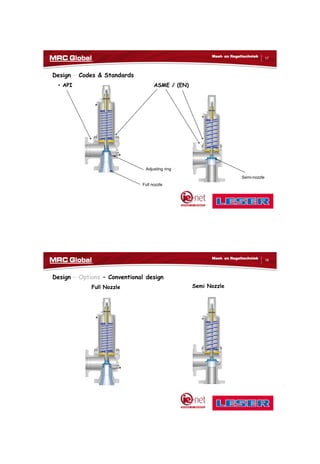

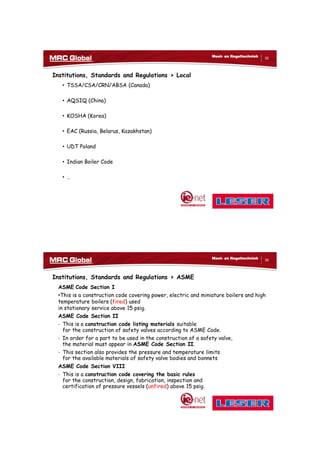

Set pressure – CDTP – Overpressure - Blowdown

Influence of Temperature - Estimation of CDTP in Theory

Set Pressure 10 bar

Operation

Required spring force 2.000 N

Medium temperature 300 °C

Spring rate at 300°C

medium temperature

95 N/mm

Spring preloaded 21 mm

CDTP (acc. LDeS 1001.69

+ 0,5 bar temperature correction)

10,5 bar

Test bench

Spring preloaded 21 mm

Spring rate at 20°C

temperature at test lab

100 N/mm

Spring force 2.100 N

52

Meet- en Regeltechniek

Set pressure – CDTP – Overpressure - Blowdown

Influence of Temperature - Estimation of CDTP in Practice

-508 -308 -108 92 292 492 692 892

0,96

0,98

1

1,02

1,04

1,06

1,08

1,1

1,12

-300 -200 -100 0 100 200 300 400 500

Temperature T [°F]

CorrectionfactorkT

Temperature T [°C]

Conventional design with closed bonnet

upward set pressure (+3%) of allowable tolerances ( 3%)

according to EN ISO 4126-1 2003-09

downward set pressure (-3%) of allowable tolarance

( 3) according to EN ISO 4126-1 2003-09

Approved correction curve by

German TÜV Nord](https://image.slidesharecdn.com/ienetpresentationmrcglobalmdj-171018103727/85/Pressure-Relief-Devices-26-320.jpg)