This document describes using ASPEN Plus dynamic simulation software to model and control a continuous stirred tank reactor (CSTR) process. It introduces key dynamic simulation concepts and outlines the steps to:

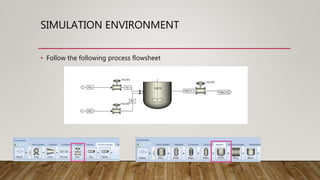

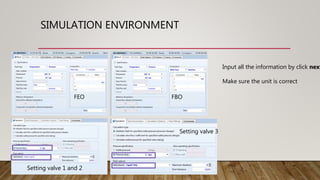

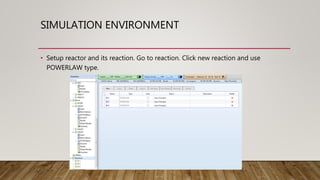

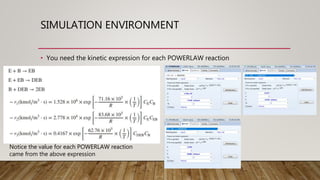

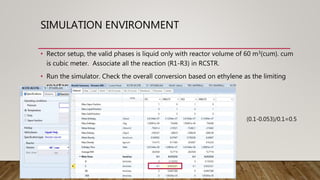

1) Build a process flowsheet model in steady-state, including reactions, streams and equipment.

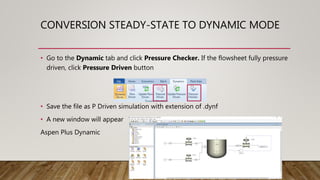

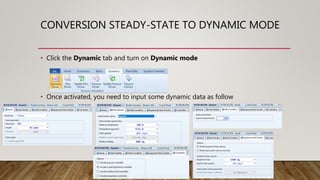

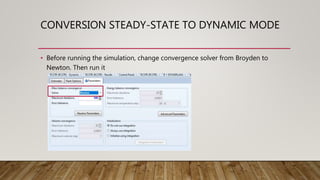

2) Convert the model to dynamic mode and input dynamic parameters.

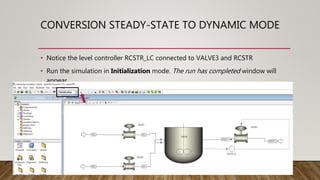

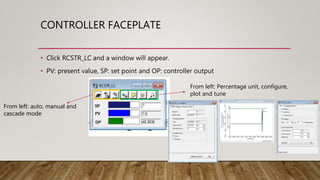

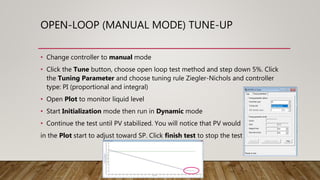

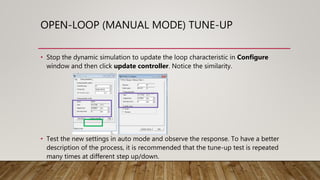

3) Add a level controller to the CSTR and tune it using open-loop testing and the Ziegler-Nichols method.

4) Simulate the dynamic behavior of the controlled process to evaluate controller performance.

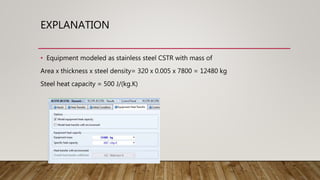

![EXPLANATION

• Temperature approach is LMTD, logarithmic mean temperature difference.

• LMTD=[(400-298)-(400-343)]/ln(102/57)]=77.33K; heat capacity water 4200J/kg.K

• 400 K refer to reactor temperature which need to maintain. 298 and 343 K refer to

coolant temperature enter and leave the jacket.](https://image.slidesharecdn.com/aspendynamic-220110032923/85/Aspen-Plus-dynamic-15-320.jpg)