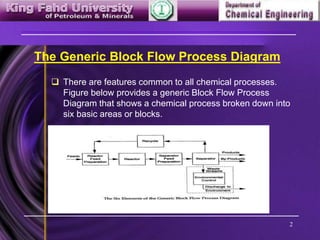

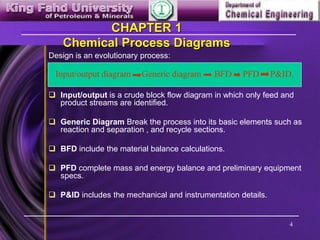

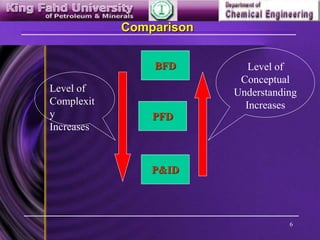

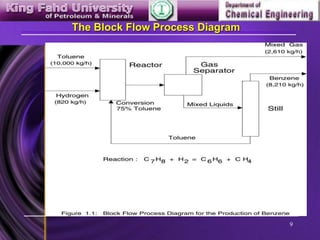

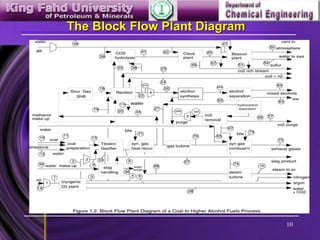

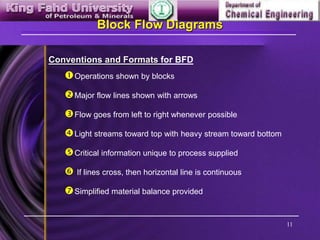

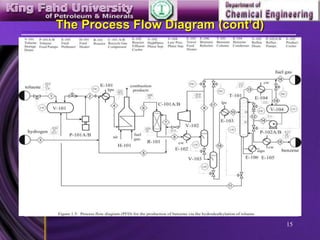

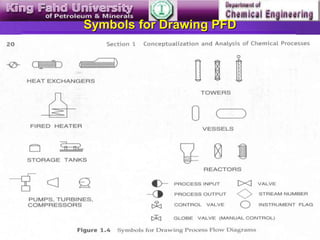

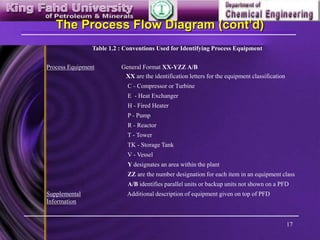

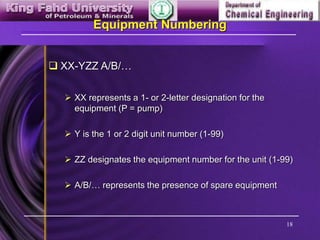

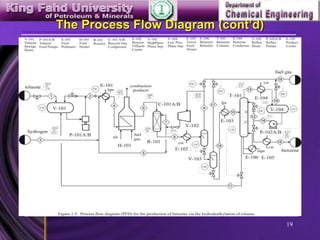

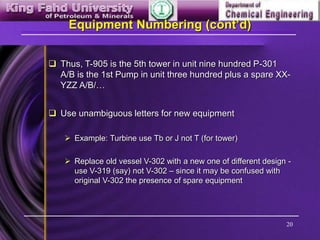

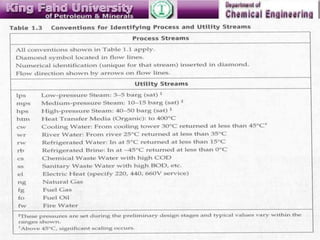

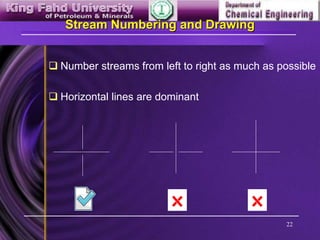

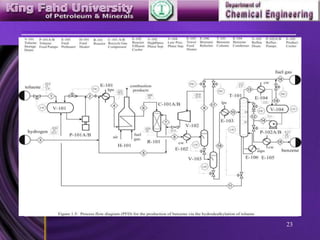

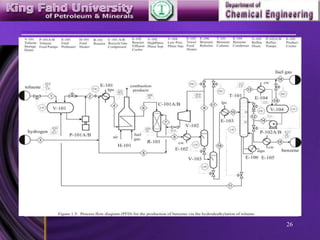

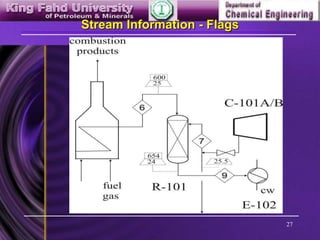

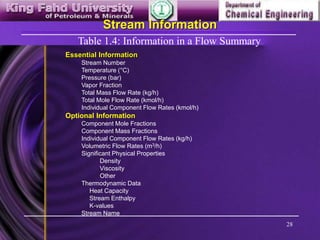

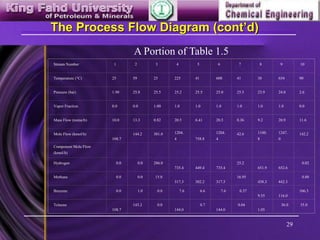

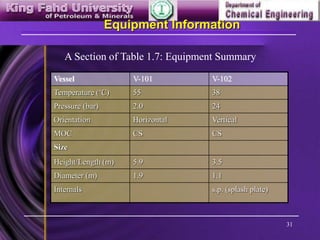

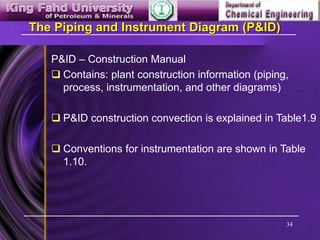

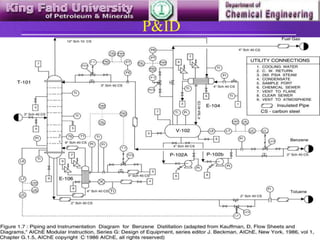

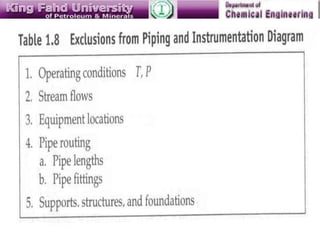

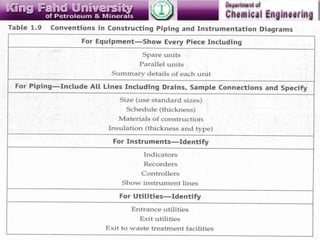

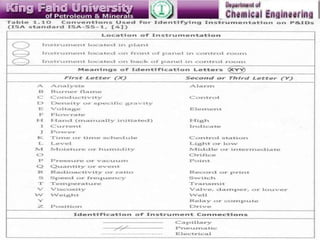

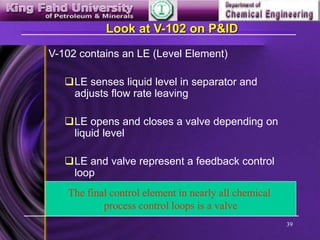

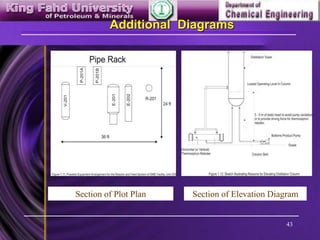

The document discusses chemical process diagrams and their importance in communicating process information. It describes three main levels of diagrams - block flow diagrams (BFD), process flow diagrams (PFD), and piping and instrumentation diagrams (P&ID). BFDs provide a conceptual overview of the process while PFDs contain detailed mass and energy balance information. P&IDs include piping, instrumentation, and control details. The document explains conventions for streams, equipment, and other elements in PFDs and P&IDs and provides examples of these diagrams. It also discusses additional diagrams like plot plans and 3D models used for design.