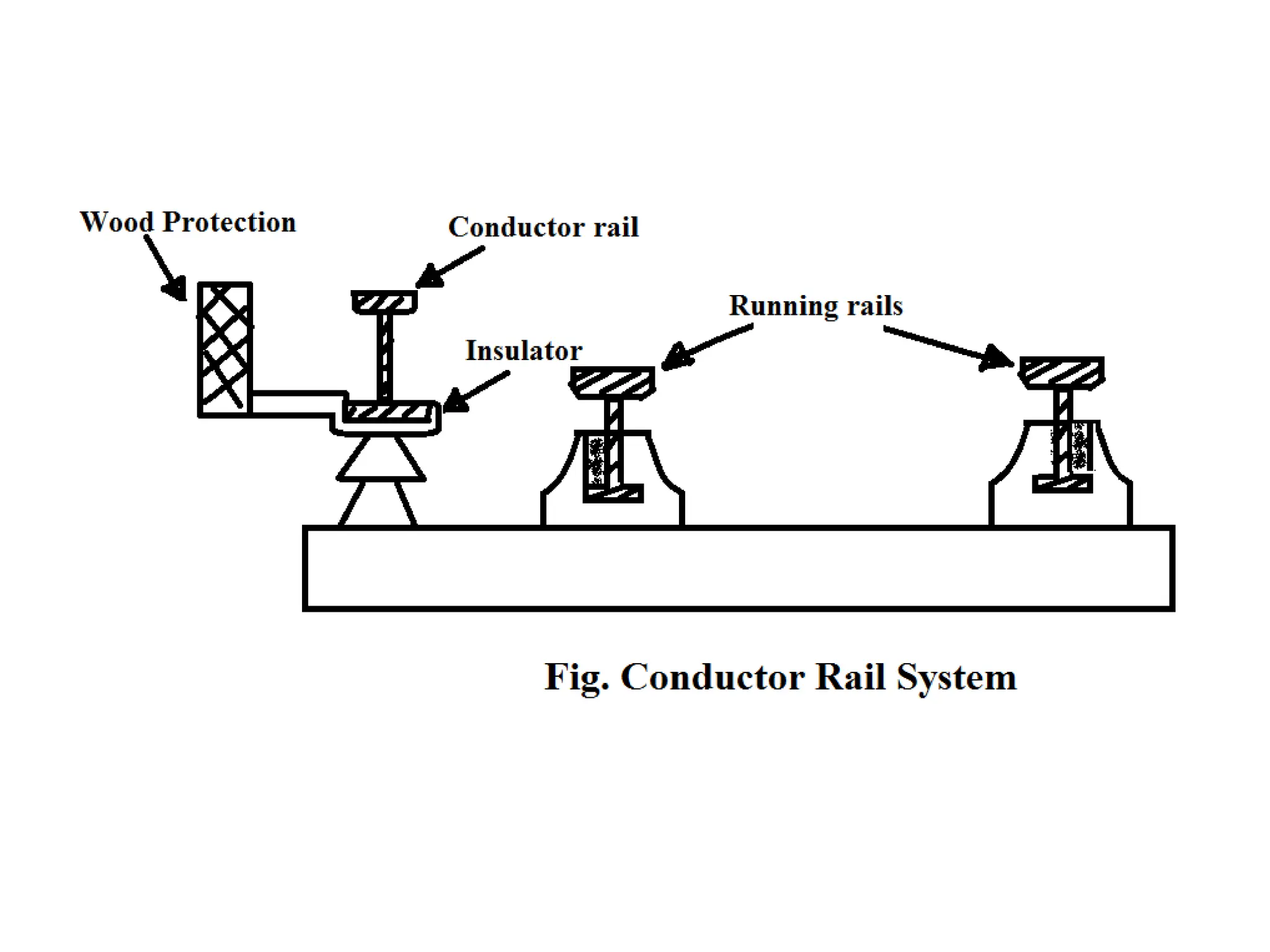

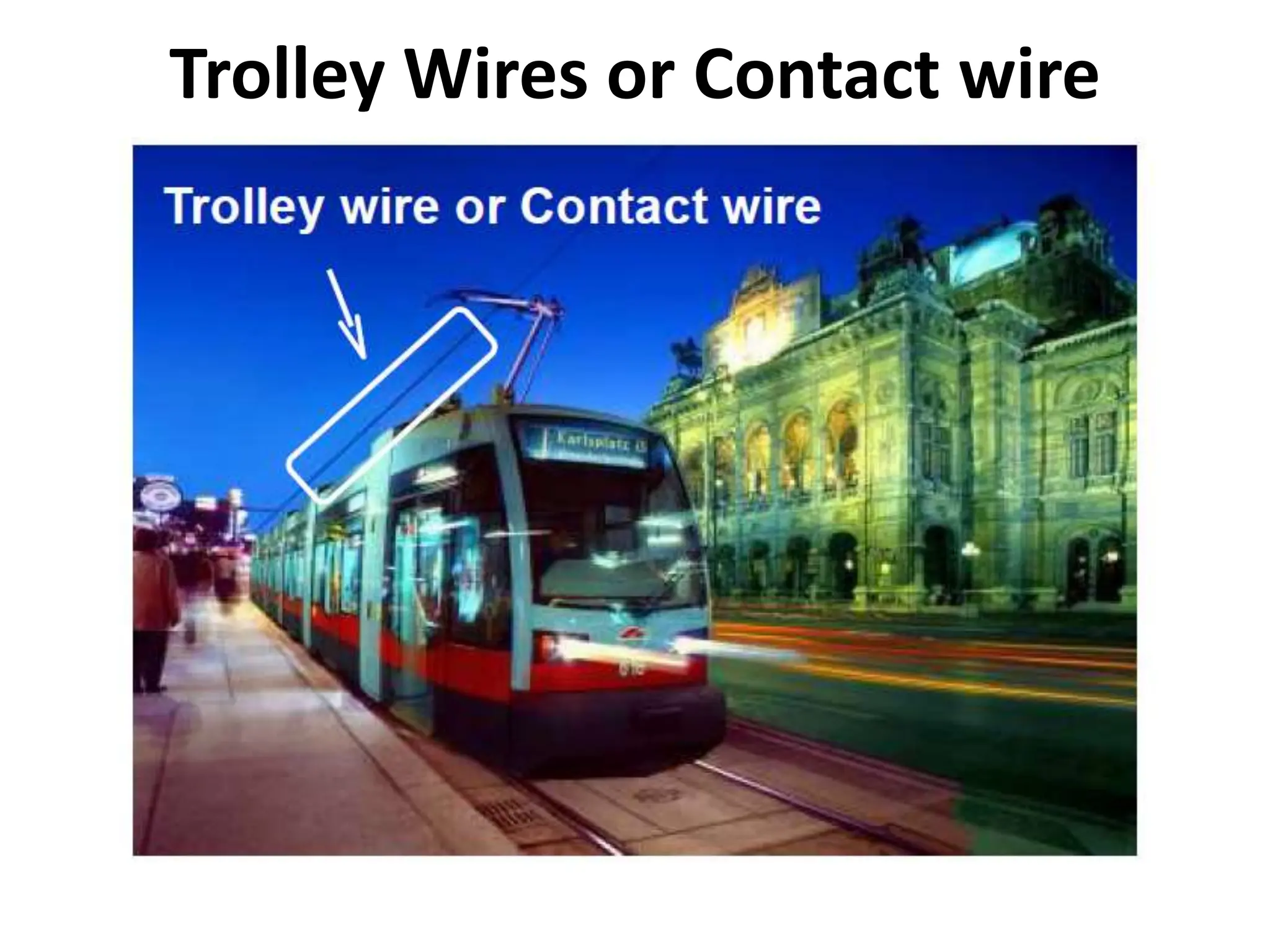

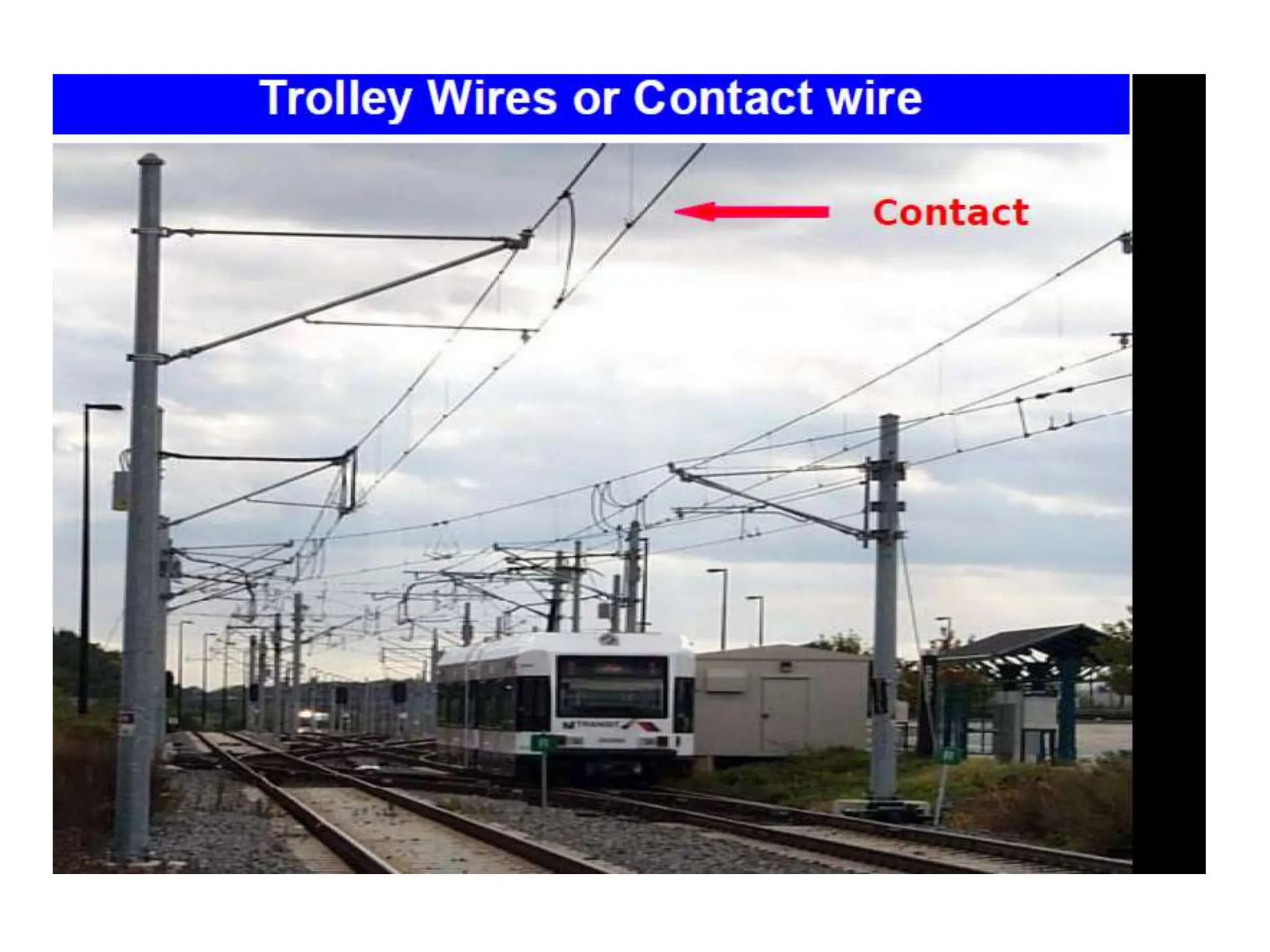

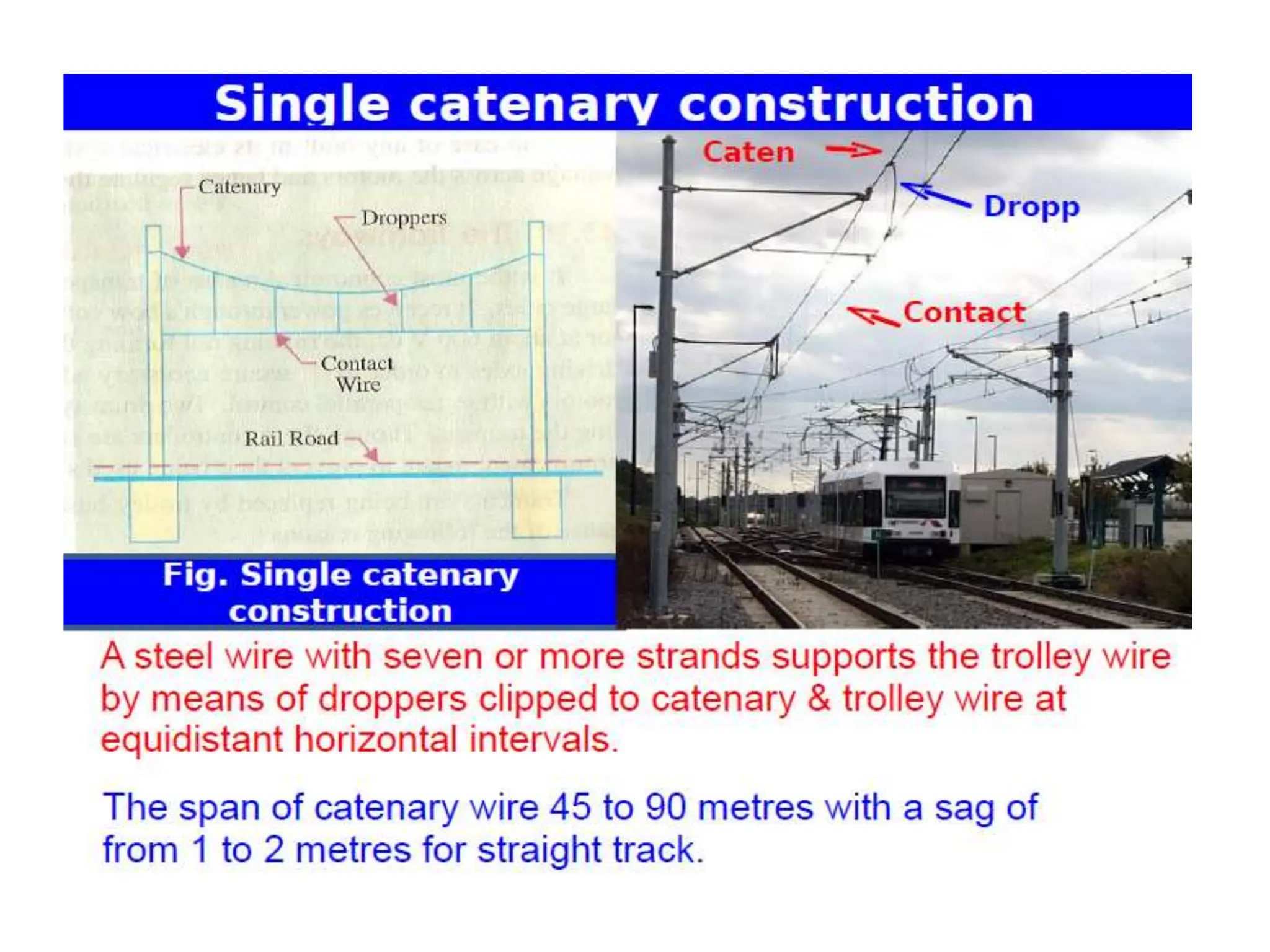

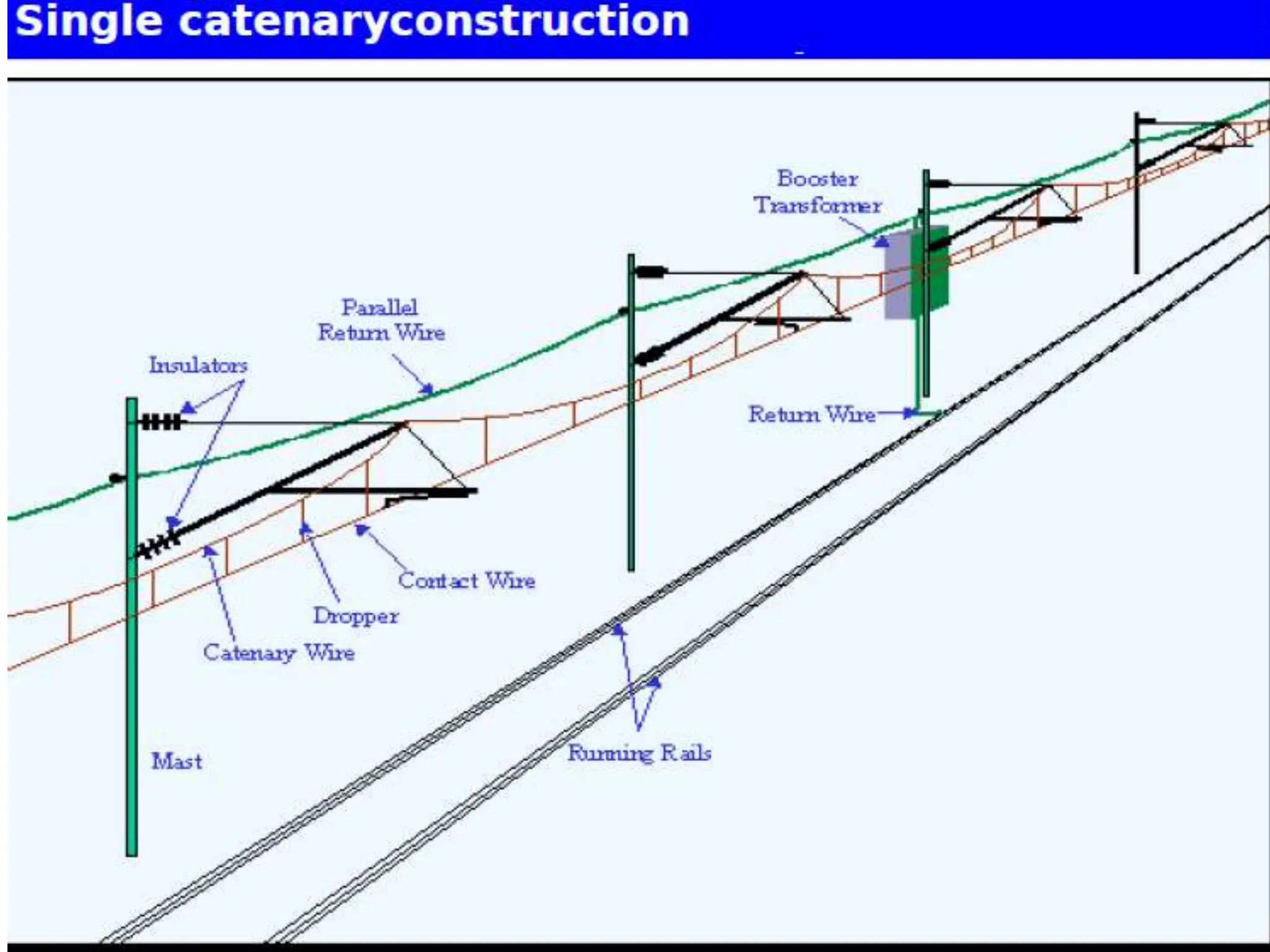

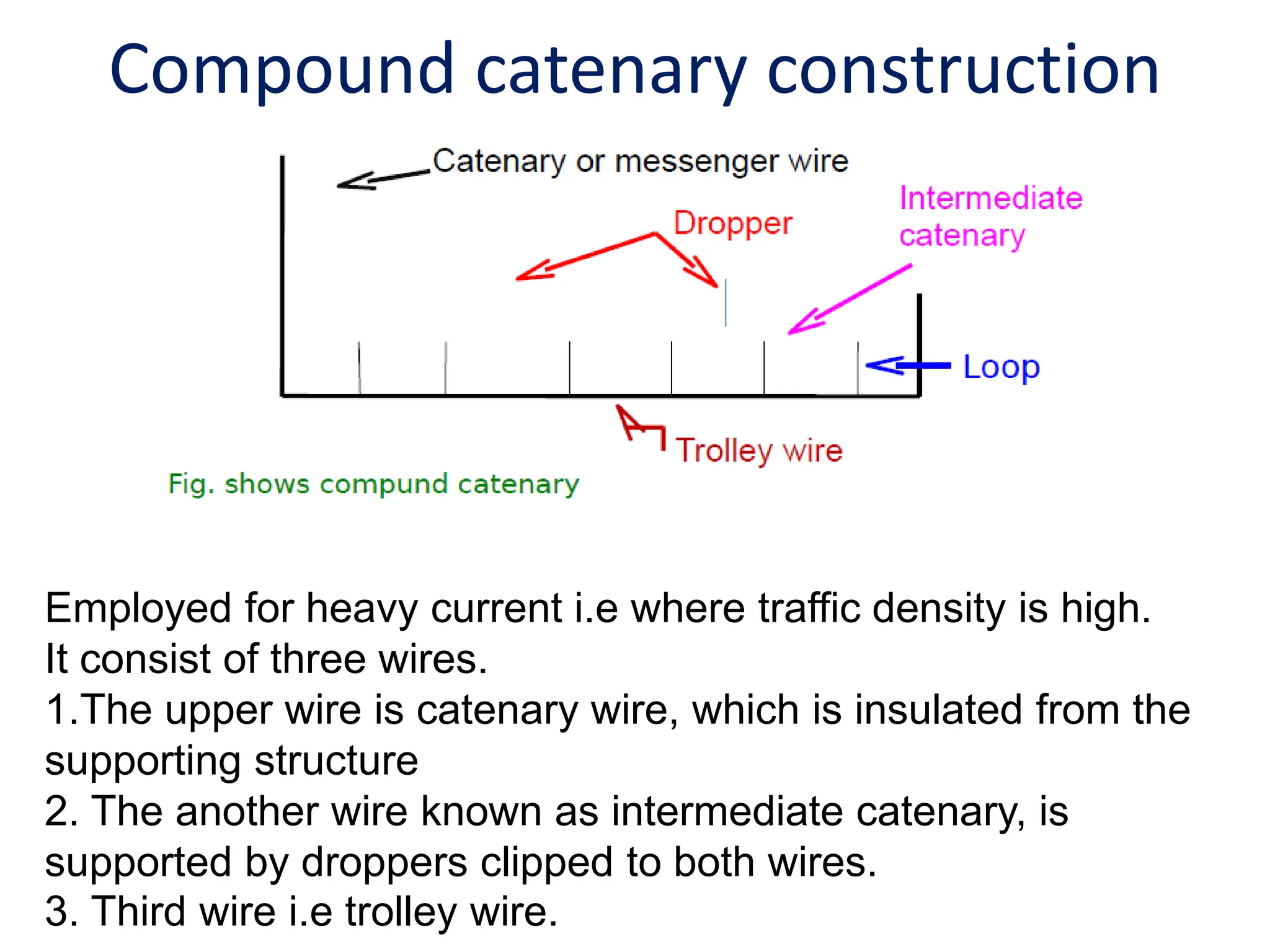

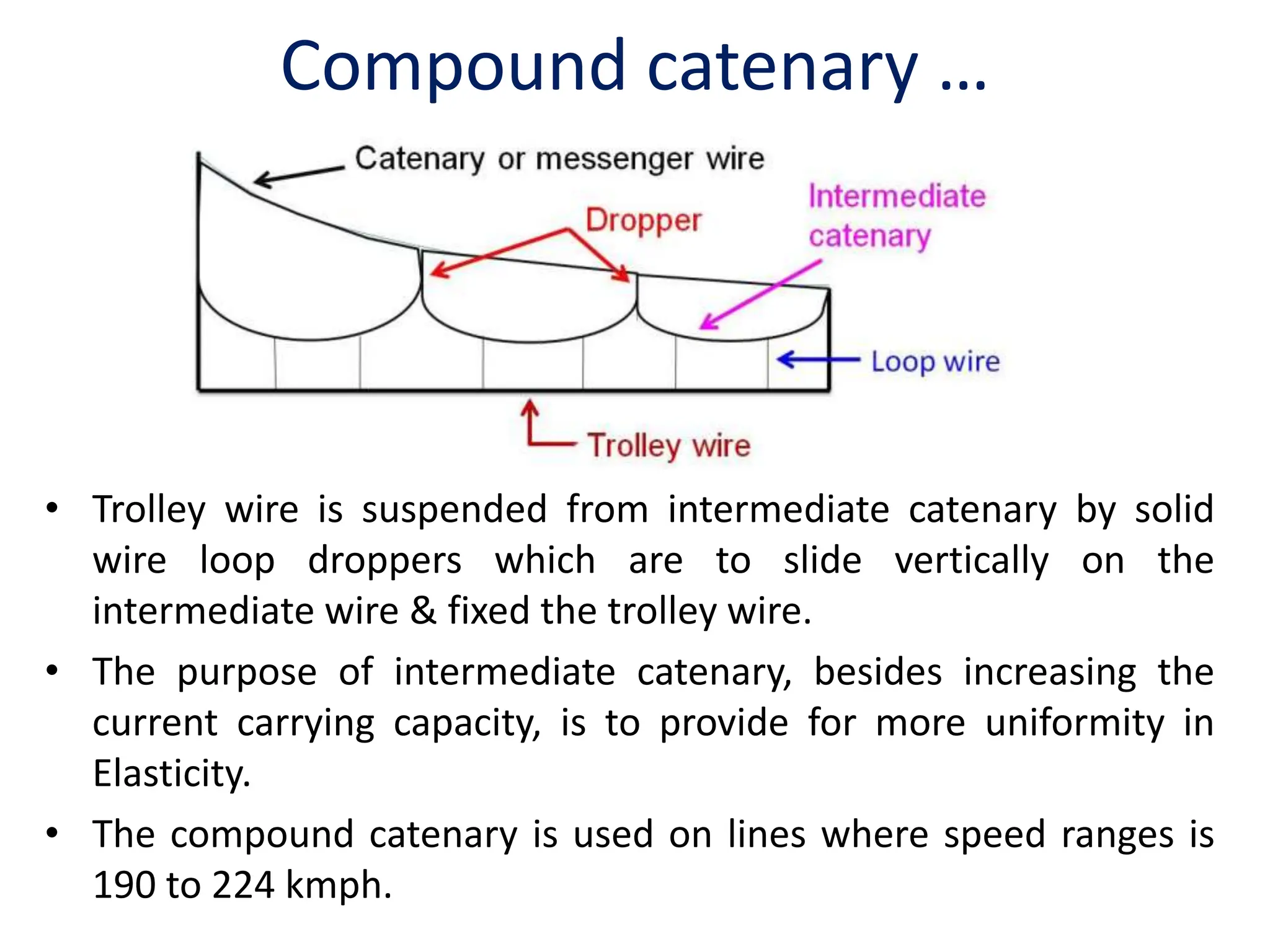

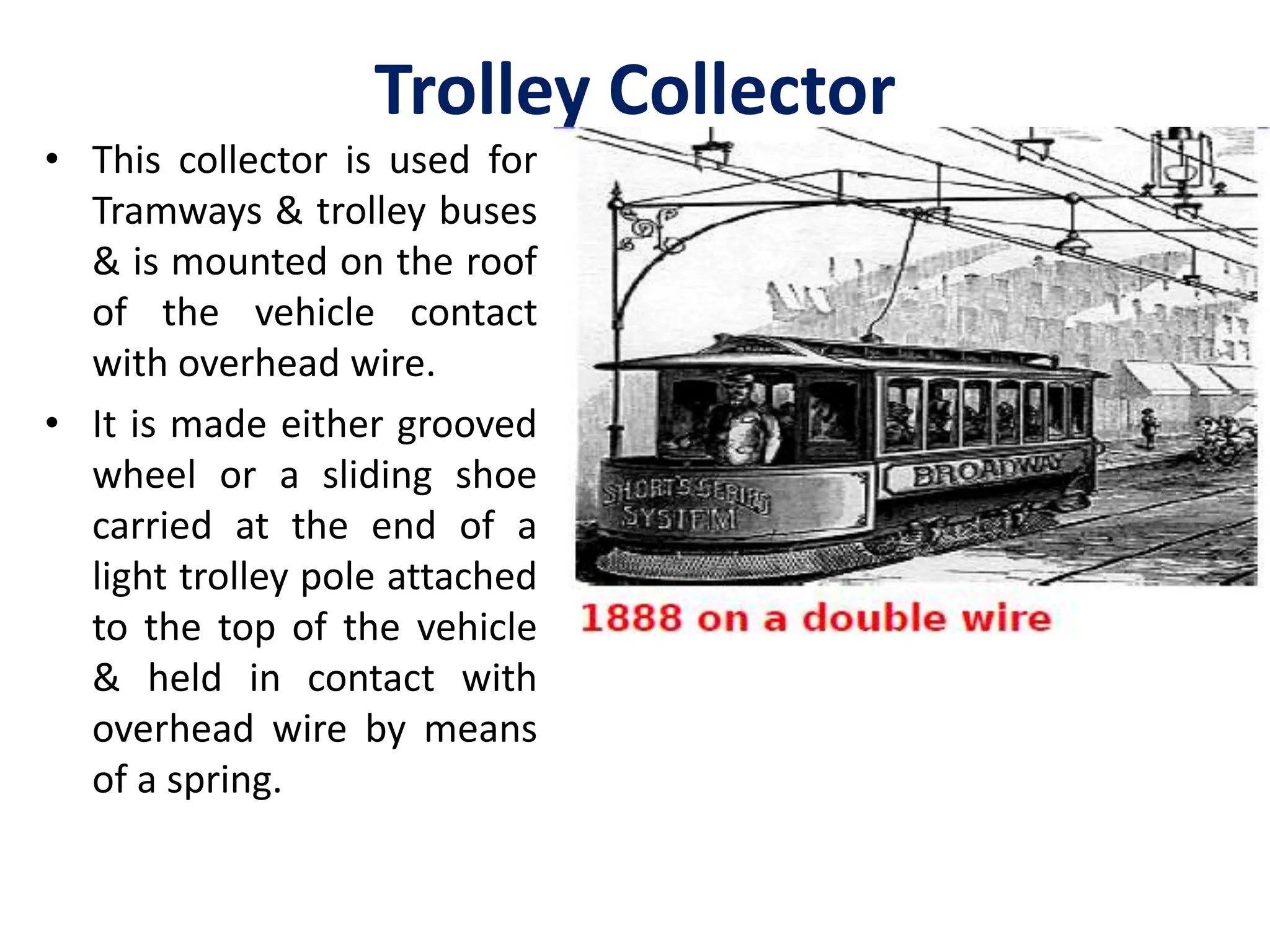

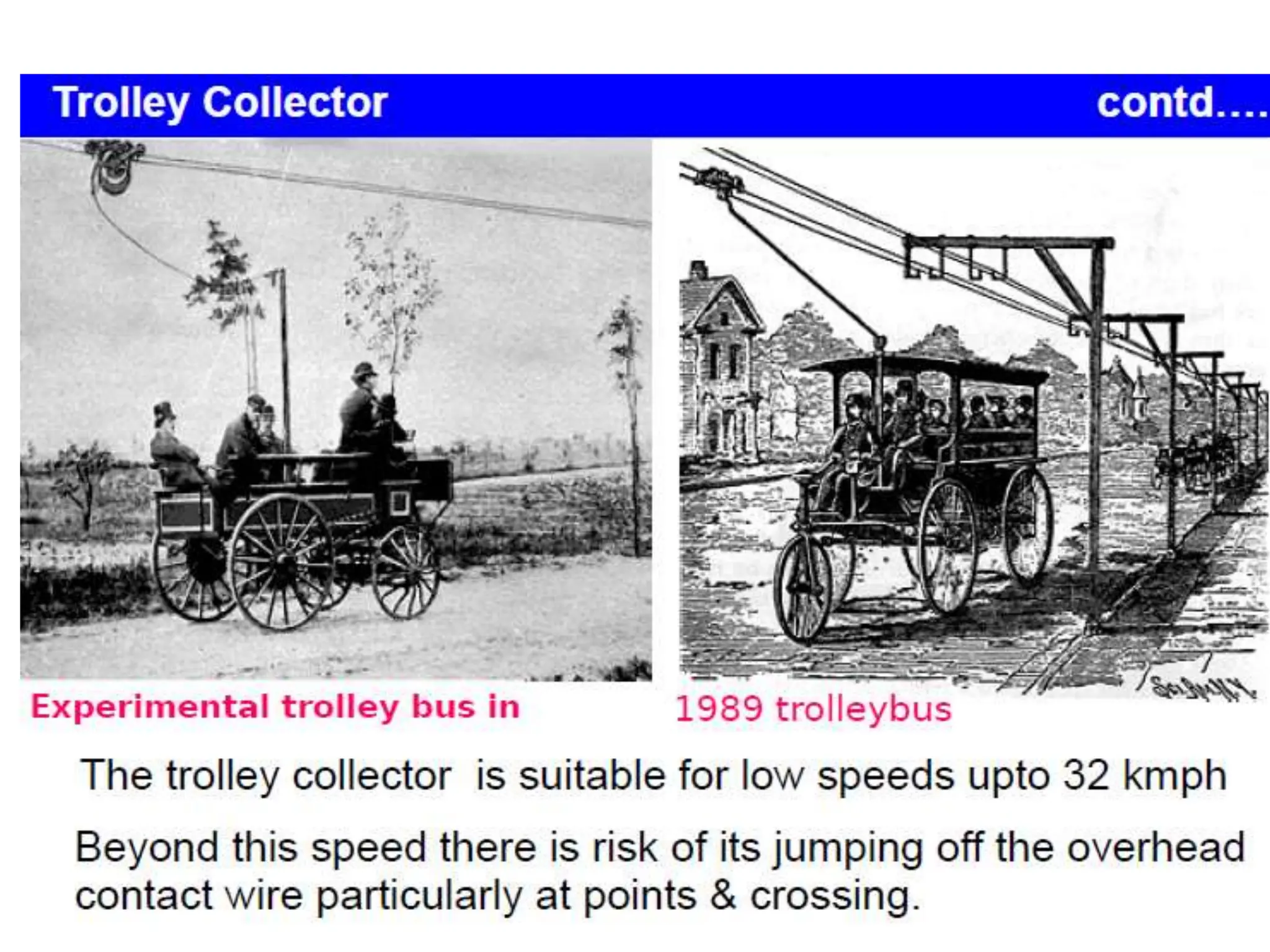

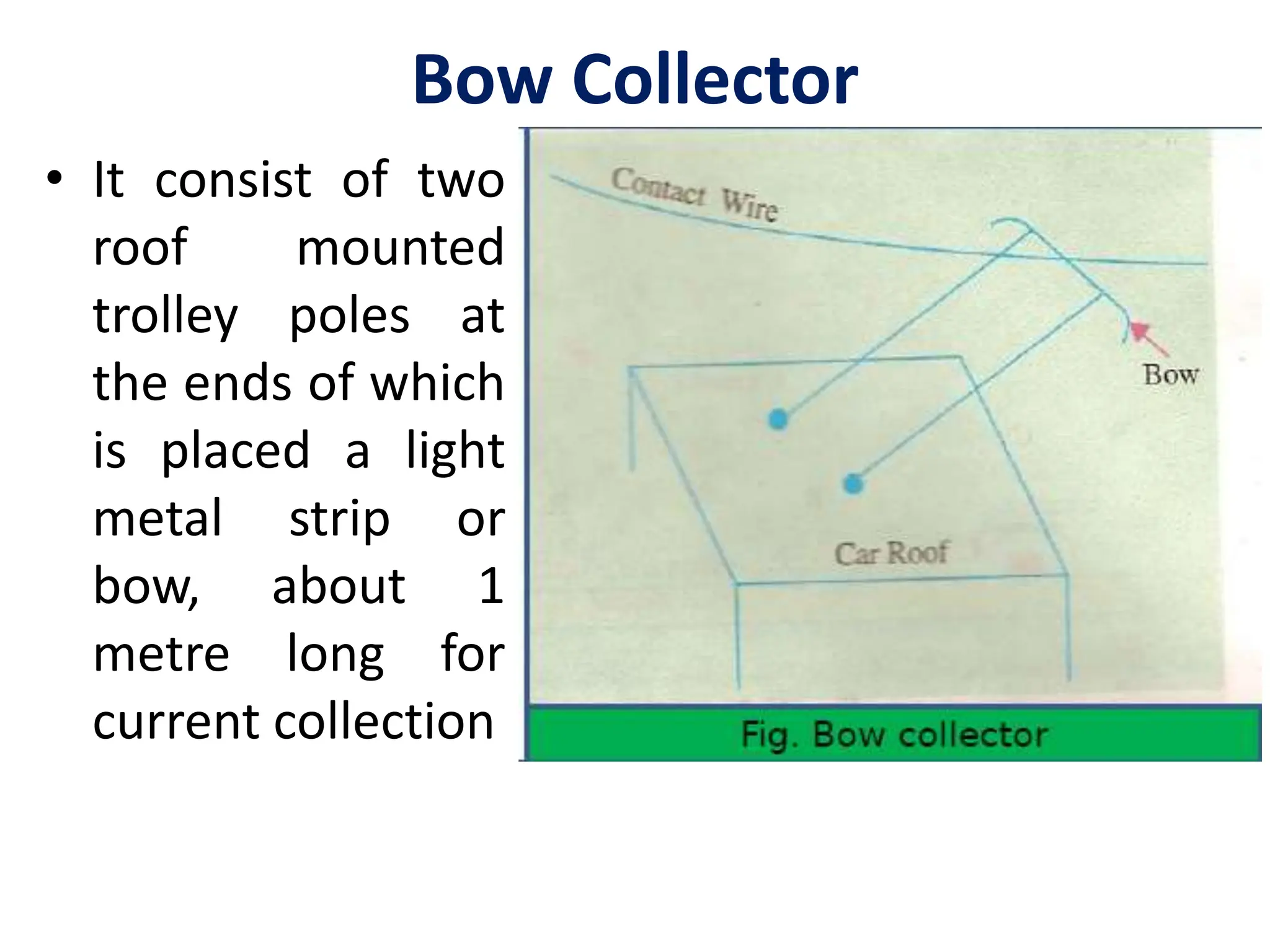

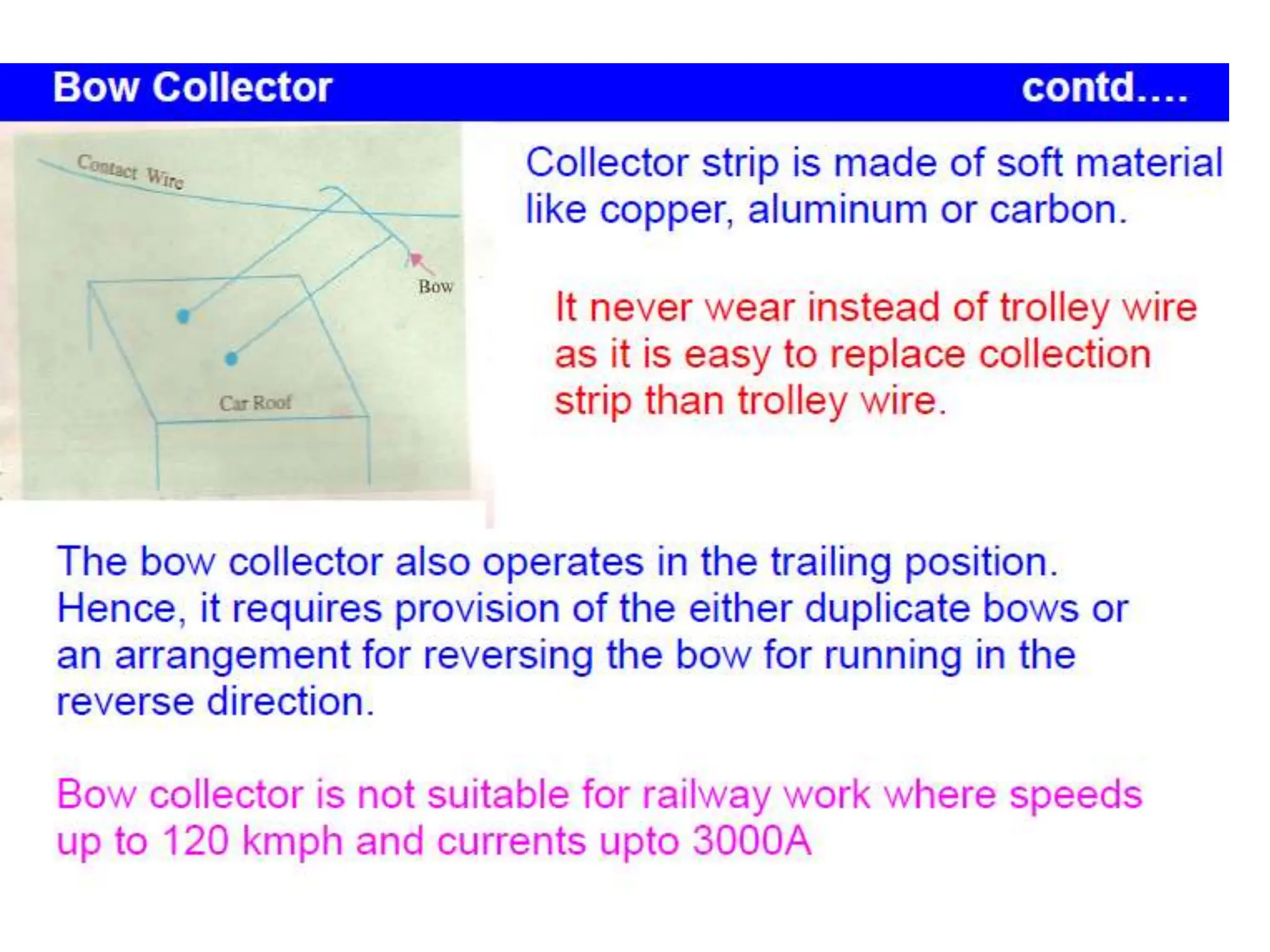

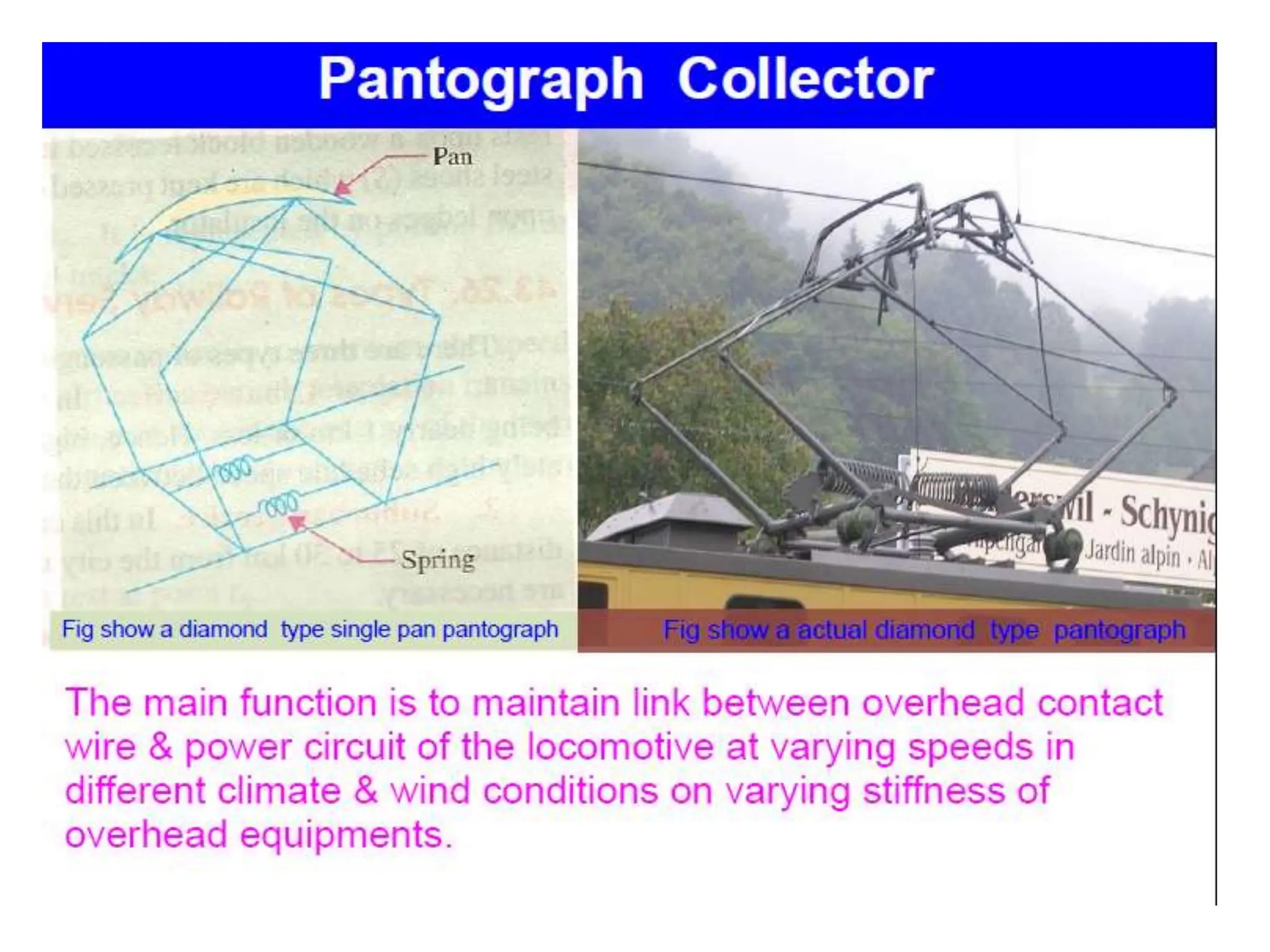

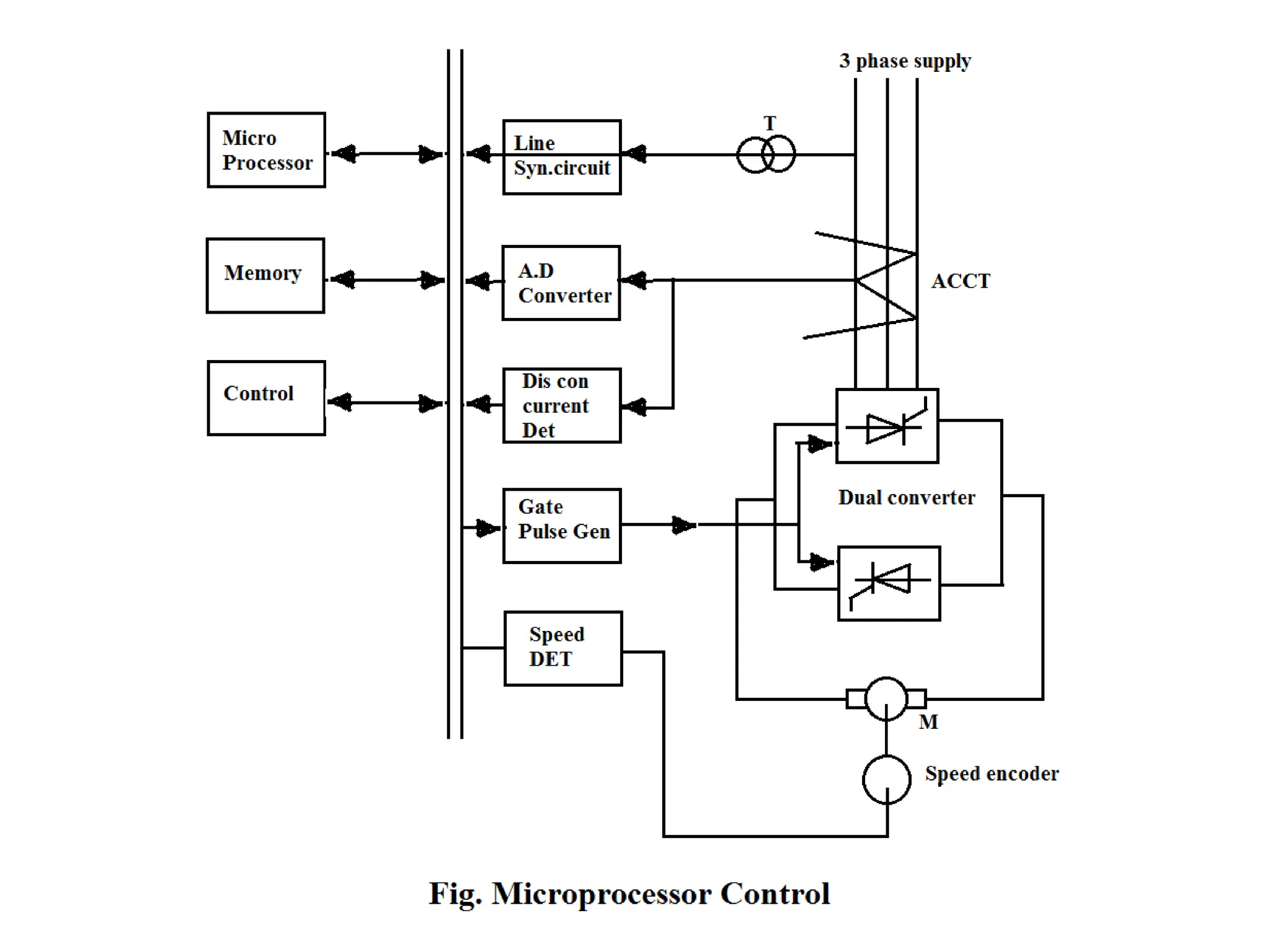

The document summarizes different systems for collecting current on locomotives, trams, and trolley buses. It describes the conductor rail system and overhead system, providing details on how each system distributes current. It then focuses on the overhead system, explaining the trolley wire/contact wire, catenary construction, and different types of current collectors like the trolley collector, bow collector, and pantograph collector. The document concludes by discussing recent trends in electric traction technology like PWM inverters and advanced speed control methods.