Process Calculation - simple distillation

•

0 likes•3,394 views

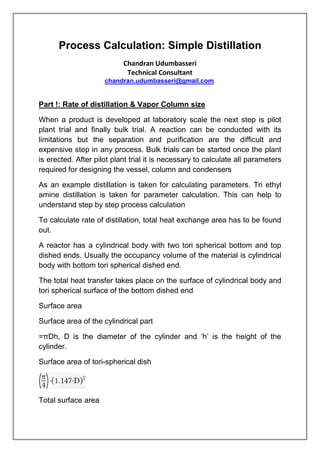

This document provides calculations for the rate of distillation and size of a vapor column for distilling triethyl amine. It calculates the total heat transfer area and rate of vaporization as 1410.218 kg/hr. The diameter of the vapor column is calculated as approximately 4 inches and the height is approximately 10 feet. Various equations and data are presented to illustrate the step-by-step calculations and determine the necessary parameters for designing distillation equipment.

Report

Share

Report

Share

Download to read offline

Recommended

Process calculation condensation

This document describes the calculation used for the shell and tube heat exchanger

Distillation Column Design

An overview of distillation column design concepts and major design considerations. Explains distillation column design concepts, what you would provide to a professional distillation column designer, and what you can expect back from a distillation system design firm. To speak with an engineer about your distillation column project, call EPIC at 314-207-4250.

Types of Distillation & column internals

More:- https://chemicalengineeringworld.com

Distillation is a method of separating the components of a solution which depends upon distribution of the substances between a gas and liquid phase, applied to cases where all components are present in both phases.

* What is distillation ?

* Types of Distillation

* Batch Distillation

* Azeotropic Distillation

* Flooding

* Priming

* Coning

* Weeping

* Dumping

* Packed Column

* Tray column

* Reflux Ratio

* Relative volatility

* Distillation column

Distillation is a method of separating mixtures based on differences in volatility (volatility is the tendency of a substance to vaporize. Volatility is directly related to a substance's vapor pressure.) of components in a boiling liquid mixture. Distillation is a unit operation, or a physical separation process, and not a chemical reaction

Processing of petroleum types of reflux

PROCESSING OF PETROLEUM :TYPES OF REFLUX

arrangements of distillation towers

Pump back reflux and pump around reflux

Side stripping columns

process refining & petrochemicals

Selection and Design of Condensers

Selection and Design of Condensers

0 INTRODUCTION/PURPOSE

1 SCOPE

2 FIELD OF APPLICATION

3 DEFINITIONS

4 CHOICE OF COOLANT

5 LAYOUT CONSIDERATIONS

5.1 Distillation Column Condensers

5.2 Other Process Condensers

6 CONTROL

6.1 Distillation Columns

6.2 Water Cooled Condensers

6.3 Refrigerant Condensers

7 GENERAL DESIGN CONSIDERATIONS

7.1 Heat Transfer Resistances

7.2 Pressure Drop

7.3 Handling of Inerts

7.4 Vapor Inlet Design

7.5 Drainage of Condensate

8 SUMMARY OF TYPES AVAILABLE

8.1 Direct Contact Condensers

8.2 Shell and Tube Exchangers

8.3 Air Cooled Heat Exchangers

8.4 Spiral Plate Heat Exchangers

8.5 Internal Condensers

8.6 Plate Heat Exchangers

8.7 Plate-Fin Heat Exchangers

8.8 Other Compact Designs

9 BIBLIOGRAPHY

FIGURES

1 DIRECT CONTACT CONDENSER WITH INDIRECT COOLER FOR RECYCLED CONDENSATE

2 SPRAY CONDENSER

3 TRAY TYPE CONDENSER

4 THREE PASS TUBE SIDE CONDENSER WITH INTERPASS LUTING FOR CONDENSATE DRAINAGE

5 CROSS FLOW CONDENSER WITH SINGLE PASS COOLANT

Thermosyphon Reboiler & its type with operational parameter.

introduction to reboiler ,its type,.

introduction to thermosyphon reboiler.

Recommended

Process calculation condensation

This document describes the calculation used for the shell and tube heat exchanger

Distillation Column Design

An overview of distillation column design concepts and major design considerations. Explains distillation column design concepts, what you would provide to a professional distillation column designer, and what you can expect back from a distillation system design firm. To speak with an engineer about your distillation column project, call EPIC at 314-207-4250.

Types of Distillation & column internals

More:- https://chemicalengineeringworld.com

Distillation is a method of separating the components of a solution which depends upon distribution of the substances between a gas and liquid phase, applied to cases where all components are present in both phases.

* What is distillation ?

* Types of Distillation

* Batch Distillation

* Azeotropic Distillation

* Flooding

* Priming

* Coning

* Weeping

* Dumping

* Packed Column

* Tray column

* Reflux Ratio

* Relative volatility

* Distillation column

Distillation is a method of separating mixtures based on differences in volatility (volatility is the tendency of a substance to vaporize. Volatility is directly related to a substance's vapor pressure.) of components in a boiling liquid mixture. Distillation is a unit operation, or a physical separation process, and not a chemical reaction

Processing of petroleum types of reflux

PROCESSING OF PETROLEUM :TYPES OF REFLUX

arrangements of distillation towers

Pump back reflux and pump around reflux

Side stripping columns

process refining & petrochemicals

Selection and Design of Condensers

Selection and Design of Condensers

0 INTRODUCTION/PURPOSE

1 SCOPE

2 FIELD OF APPLICATION

3 DEFINITIONS

4 CHOICE OF COOLANT

5 LAYOUT CONSIDERATIONS

5.1 Distillation Column Condensers

5.2 Other Process Condensers

6 CONTROL

6.1 Distillation Columns

6.2 Water Cooled Condensers

6.3 Refrigerant Condensers

7 GENERAL DESIGN CONSIDERATIONS

7.1 Heat Transfer Resistances

7.2 Pressure Drop

7.3 Handling of Inerts

7.4 Vapor Inlet Design

7.5 Drainage of Condensate

8 SUMMARY OF TYPES AVAILABLE

8.1 Direct Contact Condensers

8.2 Shell and Tube Exchangers

8.3 Air Cooled Heat Exchangers

8.4 Spiral Plate Heat Exchangers

8.5 Internal Condensers

8.6 Plate Heat Exchangers

8.7 Plate-Fin Heat Exchangers

8.8 Other Compact Designs

9 BIBLIOGRAPHY

FIGURES

1 DIRECT CONTACT CONDENSER WITH INDIRECT COOLER FOR RECYCLED CONDENSATE

2 SPRAY CONDENSER

3 TRAY TYPE CONDENSER

4 THREE PASS TUBE SIDE CONDENSER WITH INTERPASS LUTING FOR CONDENSATE DRAINAGE

5 CROSS FLOW CONDENSER WITH SINGLE PASS COOLANT

Thermosyphon Reboiler & its type with operational parameter.

introduction to reboiler ,its type,.

introduction to thermosyphon reboiler.

Gas Absorption Laboratory Experiment

Gas Absorption Experiment performed in lab during my Junior year at Drexel University.

Aspen HYSYS - Petroleum Assays and Oil Characterization (Slideshare)

This is course on Plant Simulation will show you how to setup hypothetical compounds, oil assays, blends, and petroleum characterization using the Oil Manager of Aspen HYSYS.

You will learn about:

Hypothetical Compounds (Hypos)

Estimation of hypo compound data

Models via Chemical Structure UNIFAC Component Builder

Basis conversion/cloning of existing components

Input of Petroleum Assay and Crude Oils

Typical Bulk Properties (Molar Weight, Density, Viscosity)

Distillation curves such as TBP (Total Boiling Point)

ASTM (D86, D1160, D86-D1160, D2887)

Chromatography

Light End

Oil Characterization

Using the Petroleum Assay Manager or the Oil Manager

Importing Assays: Existing Database

Creating Assays: Manually / Model

Cutting: Pseudocomponent generation

Blending of crude oils

Installing oils into Aspen HYSYS flowsheets

Getting Results (Plots, Graphs, Tables)

Property and Composition Tables

Distribution Plot (Off Gas, Light Short Run, Naphtha, Kerosene, Light Diesel, Heavy Diesel, Gasoil, Residue)

Oil Properties

Proper

Boiling Point Curves

Viscosity, Density, Molecular Weight Curves

This is helpful for students, teachers, engineers and researchers in the area of R&D, specially those in the Oil and Gas or Petroleum Refining industry.

This is a "workshop-based" course, there is about 25% theory and about 75% work!

At the end of the course you will be able to handle crude oils for your fractionation, refining, petrochemical process simulations!

Parts of shell and tube heat exchanger

Parts of shell and tube heat exchanger

Shell

Shell Side Pass Partition Plate

Baffles

Tube

Tube Side Pass Partition Plate

Tie Rods

Spacers

Tube Sheet

Expansion Joint

Perry’s Chemical Engineers’ Handbook 7ma Ed Chap 12

Versión en Ingles de manual del ingeniero químico, 7ma edición. Capitulo 12

Reactor and Catalyst Design

Reactor and Catalyst Design

0 INTRODUCTION/PURPOSE

1 SCOPE

2 FIELD OF APPLICATION

3 DEFINITIONS

4 CATALYST DESIGN

4.1 Equivalent Pellet Diameter

4.2 Voidage

4.3 Pellet Density

5 REACTOR DESIGN

6 CATALYST SUPPORT

6.1 Choice of Support

TABLES

1 CATALYST SUPPORT SHAPES

2 SECONDARY REFORMER SPREADSHEET

FIGURES

1 GRAPH OF EFFECTIVENESS v THIELE MODULUS

2 VARIATION OF COSTS WITH CATALYST SIZE

3 VARIATION OF COSTS WITH CATALYST BED VOIDAGE

4 VARIATION OF COSTS WITH VESSEL DIAMETER

2.2 McCabe-Thiele method

Slides for the eLearning course Separation and purification processes in biorefineries (https://open-learn.xamk.fi) in IMPRESS project (https://www.spire2030.eu/impress).

Section: Distillation

Subject: 0.2 Introduction to distillation.

The Design and Layout of Vertical Thermosyphon Reboilers

The Design and Layout of Vertical Thermosyphon Reboilers

0 INTRODUCTION/PURPOSE

1 SCOPE

2 FIELD OF APPLICATION

3 DEFINITIONS

4 THE DESIGN PROBLEM

5 COMPUTER PROGRAMS

6 GENERAL CONSIDERATIONS

6.1 Heating Medium Temperature

6.2 Fouling Resistance

7 DESIGN PARAMETERS

7.1 Overall Arrangement and Specifications

7.2 Geometry Elements

8 ANALYSIS OF COMMERCIALLY AVAILABLE

PROGRAM RESULTS

8.1 Main Results

8.2 Supplementary Results

8.3 Error Analysis

8.4 Adjustments to Design

9 OPERATING RANGE

10 CONTROL

10.1 Control of Condensing Heating Medium Pressure

10.2 Control of The Condensate Level

10.3 Control of Sensible Fluid Flow Rate

11 LAYOUT

11.1 Factors Influencing Design

11.2 A Standard Layout

12 BIBLIOGRAPHY

Design of thermosyphon reboiler

Thermosiphon reboilers in chemical industry has wide scope for usage. The PDF will provide introduction, types and design methodology that.

Calculation of an Ammonia Plant Energy Consumption:

Calculation of an Ammonia Plant Energy Consumption:

Case Study: #06023300

Plant Note Book Series: PNBS-0602

CONTENTS

0 SCOPE

1 CALCULATION OF NATURAL GAS PROCESS FEED CONSUMPTION

2 CALCULATION OF NATURAL GAS PROCESS FUEL CONSUMPTION

3 CALCULATION OF NATURAL GAS CONSUMPTION FOR PILOT BURNERS OF FLARES

4 CALCULATION OF DEMIN. WATER FROM DEMIN. UNIT

5 CALCULATION OF DEMIN. WATER TO PACKAGE BOILERS

6 CALCULATION OF MP STEAM EXPORT

7 CALCULATION OF LP STEAM IMPORT

8 DETERMINATION OF ELECTRIC POWER CONSUMPTION

9 DETERMINATION OF THE TOTAL ENERGY CONSUMPTION OF THE AMMONIA PLANT ISBL

10 ADJUSTMENT OF ELECTRIC POWER CONSUMPTION FOR TEST RUN CONDITIONS

11 CALCULATION OF AMMONIA SHARE IN MP STEAM CONSUMPTION IN UTILITIES

12 CALCULATION OF AMMONIA SHARE IN ELECTRIC POWER CONSUMPTION IN UTILITIES

13 DETERMINATION OF THE TOTAL ENERGY CONSUMPTION OF THE AMMONIA PLANT OSBL

14 DETERMINATION OF THE TOTAL ENERGY CONSUMPTION OF THE AMMONIA PLANT

Gas Absorption & Stripping in Chemical Engineering (Part 2/4)

COURSE LINK:

https://www.chemicalengineeringguy.com/courses/gas-absorption-stripping/

Introduction:

Gas Absorption is one of the very first Mass Transfer Unit Operations studied in early process engineering. It is very important in several Separation Processes, as it is used extensively in the Chemical industry.

Understanding the concept behind Gas-Gas and Gas-Liquid mass transfer interaction will allow you to understand and model Absorbers, Strippers, Scrubbers, Washers, Bubblers, etc…

We will cover:

- REVIEW: Of Mass Transfer Basics required

- GAS-LIQUID interaction in the molecular level, the two-film theory

- ABSORPTION Theory

- Application of Absorption in the Industry

- Counter-current & Co-current Operation

- Several equipment to carry Gas-Liquid Operations

- Bubble, Spray, Packed and Tray Column equipments

- Solvent Selection

- Design & Operation of Packed Towers

- Pressure drop due to packings

- Solvent Selection

- Design & Operation of Tray Columns

- Single Component Absorption

- Single Component Stripping/Desorption

- Diluted and Concentrated Absorption

- Basics: Multicomponent Absorption

- Software Simulation for Absorption/Stripping Operations (ASPEN PLUS/HYSYS)

----

Please show the love! LIKE, SHARE and SUBSCRIBE!

More likes, sharings, suscribers: MORE VIDEOS!

-----

CONTACT ME

Chemical.Engineering.Guy@Gmail.com

www.ChemicalEngineeringGuy.com

http://facebook.com/Chemical.Engineering.Guy

You speak spanish? Visit my spanish channel -www.youtube.com/ChemEngIQA

Shell and tube heat exchanger design

A very useful presentation about all a engineer needs to know about designing shell and tube heat exchangers.

Astm method for distillation of petroleum products at atmospheric pressure

Facebook Page :https://www.facebook.com/petroleumengineeringz

flow of falling film, transport phenomenon, navier stokes equation derivation

flow of falling film, transport phenomenon, navier stokes equation derivation

DESIGN OF AIR PRE HEATER AND ECONOMIZER

Heat/light/electrical energy is out today’s necessity and has scarcity also. Energy conservation is key requirement of any industry at all times.

In general, industries use heat energy for conservation of raw material to finished product. The source of heat energy is generally saturated or super heated steam. The steam generation is common use one boiler with carity of fuels. Whatever may be the fuel the generation should be as economy as possible which adds to the product cost. Further the usage of steam and recycling steam condensate back to boiler is an art depending on plant layouts.

In this project the steam generator is water tube boiler fired with rice husk. The steam is transferred to the tyre/tube moulds where tyres/tubes are cured while the heat is rejected to the tyres the condensate forms and this condensate is put back to the boiler. While doing so the steam is also stopped back to boiler without rejecting complete heat to the product. This gets flashed into atmosphere at feed water tank. The science of separation of condensate from steam saves energy. Better the separation more the fuel conservation.

In the steam generator the fuel is burnt to heat the water and form steam. This fuel burnt flue gas carries lot of energy, out through chimney. Prior to exhausting through the heat left in flue need to be recovered, through heat recovery mechanisms’. In this project an air-preheater condensate heat recovery unit is the major energy consuming station.

More Related Content

What's hot

Gas Absorption Laboratory Experiment

Gas Absorption Experiment performed in lab during my Junior year at Drexel University.

Aspen HYSYS - Petroleum Assays and Oil Characterization (Slideshare)

This is course on Plant Simulation will show you how to setup hypothetical compounds, oil assays, blends, and petroleum characterization using the Oil Manager of Aspen HYSYS.

You will learn about:

Hypothetical Compounds (Hypos)

Estimation of hypo compound data

Models via Chemical Structure UNIFAC Component Builder

Basis conversion/cloning of existing components

Input of Petroleum Assay and Crude Oils

Typical Bulk Properties (Molar Weight, Density, Viscosity)

Distillation curves such as TBP (Total Boiling Point)

ASTM (D86, D1160, D86-D1160, D2887)

Chromatography

Light End

Oil Characterization

Using the Petroleum Assay Manager or the Oil Manager

Importing Assays: Existing Database

Creating Assays: Manually / Model

Cutting: Pseudocomponent generation

Blending of crude oils

Installing oils into Aspen HYSYS flowsheets

Getting Results (Plots, Graphs, Tables)

Property and Composition Tables

Distribution Plot (Off Gas, Light Short Run, Naphtha, Kerosene, Light Diesel, Heavy Diesel, Gasoil, Residue)

Oil Properties

Proper

Boiling Point Curves

Viscosity, Density, Molecular Weight Curves

This is helpful for students, teachers, engineers and researchers in the area of R&D, specially those in the Oil and Gas or Petroleum Refining industry.

This is a "workshop-based" course, there is about 25% theory and about 75% work!

At the end of the course you will be able to handle crude oils for your fractionation, refining, petrochemical process simulations!

Parts of shell and tube heat exchanger

Parts of shell and tube heat exchanger

Shell

Shell Side Pass Partition Plate

Baffles

Tube

Tube Side Pass Partition Plate

Tie Rods

Spacers

Tube Sheet

Expansion Joint

Perry’s Chemical Engineers’ Handbook 7ma Ed Chap 12

Versión en Ingles de manual del ingeniero químico, 7ma edición. Capitulo 12

Reactor and Catalyst Design

Reactor and Catalyst Design

0 INTRODUCTION/PURPOSE

1 SCOPE

2 FIELD OF APPLICATION

3 DEFINITIONS

4 CATALYST DESIGN

4.1 Equivalent Pellet Diameter

4.2 Voidage

4.3 Pellet Density

5 REACTOR DESIGN

6 CATALYST SUPPORT

6.1 Choice of Support

TABLES

1 CATALYST SUPPORT SHAPES

2 SECONDARY REFORMER SPREADSHEET

FIGURES

1 GRAPH OF EFFECTIVENESS v THIELE MODULUS

2 VARIATION OF COSTS WITH CATALYST SIZE

3 VARIATION OF COSTS WITH CATALYST BED VOIDAGE

4 VARIATION OF COSTS WITH VESSEL DIAMETER

2.2 McCabe-Thiele method

Slides for the eLearning course Separation and purification processes in biorefineries (https://open-learn.xamk.fi) in IMPRESS project (https://www.spire2030.eu/impress).

Section: Distillation

Subject: 0.2 Introduction to distillation.

The Design and Layout of Vertical Thermosyphon Reboilers

The Design and Layout of Vertical Thermosyphon Reboilers

0 INTRODUCTION/PURPOSE

1 SCOPE

2 FIELD OF APPLICATION

3 DEFINITIONS

4 THE DESIGN PROBLEM

5 COMPUTER PROGRAMS

6 GENERAL CONSIDERATIONS

6.1 Heating Medium Temperature

6.2 Fouling Resistance

7 DESIGN PARAMETERS

7.1 Overall Arrangement and Specifications

7.2 Geometry Elements

8 ANALYSIS OF COMMERCIALLY AVAILABLE

PROGRAM RESULTS

8.1 Main Results

8.2 Supplementary Results

8.3 Error Analysis

8.4 Adjustments to Design

9 OPERATING RANGE

10 CONTROL

10.1 Control of Condensing Heating Medium Pressure

10.2 Control of The Condensate Level

10.3 Control of Sensible Fluid Flow Rate

11 LAYOUT

11.1 Factors Influencing Design

11.2 A Standard Layout

12 BIBLIOGRAPHY

Design of thermosyphon reboiler

Thermosiphon reboilers in chemical industry has wide scope for usage. The PDF will provide introduction, types and design methodology that.

Calculation of an Ammonia Plant Energy Consumption:

Calculation of an Ammonia Plant Energy Consumption:

Case Study: #06023300

Plant Note Book Series: PNBS-0602

CONTENTS

0 SCOPE

1 CALCULATION OF NATURAL GAS PROCESS FEED CONSUMPTION

2 CALCULATION OF NATURAL GAS PROCESS FUEL CONSUMPTION

3 CALCULATION OF NATURAL GAS CONSUMPTION FOR PILOT BURNERS OF FLARES

4 CALCULATION OF DEMIN. WATER FROM DEMIN. UNIT

5 CALCULATION OF DEMIN. WATER TO PACKAGE BOILERS

6 CALCULATION OF MP STEAM EXPORT

7 CALCULATION OF LP STEAM IMPORT

8 DETERMINATION OF ELECTRIC POWER CONSUMPTION

9 DETERMINATION OF THE TOTAL ENERGY CONSUMPTION OF THE AMMONIA PLANT ISBL

10 ADJUSTMENT OF ELECTRIC POWER CONSUMPTION FOR TEST RUN CONDITIONS

11 CALCULATION OF AMMONIA SHARE IN MP STEAM CONSUMPTION IN UTILITIES

12 CALCULATION OF AMMONIA SHARE IN ELECTRIC POWER CONSUMPTION IN UTILITIES

13 DETERMINATION OF THE TOTAL ENERGY CONSUMPTION OF THE AMMONIA PLANT OSBL

14 DETERMINATION OF THE TOTAL ENERGY CONSUMPTION OF THE AMMONIA PLANT

Gas Absorption & Stripping in Chemical Engineering (Part 2/4)

COURSE LINK:

https://www.chemicalengineeringguy.com/courses/gas-absorption-stripping/

Introduction:

Gas Absorption is one of the very first Mass Transfer Unit Operations studied in early process engineering. It is very important in several Separation Processes, as it is used extensively in the Chemical industry.

Understanding the concept behind Gas-Gas and Gas-Liquid mass transfer interaction will allow you to understand and model Absorbers, Strippers, Scrubbers, Washers, Bubblers, etc…

We will cover:

- REVIEW: Of Mass Transfer Basics required

- GAS-LIQUID interaction in the molecular level, the two-film theory

- ABSORPTION Theory

- Application of Absorption in the Industry

- Counter-current & Co-current Operation

- Several equipment to carry Gas-Liquid Operations

- Bubble, Spray, Packed and Tray Column equipments

- Solvent Selection

- Design & Operation of Packed Towers

- Pressure drop due to packings

- Solvent Selection

- Design & Operation of Tray Columns

- Single Component Absorption

- Single Component Stripping/Desorption

- Diluted and Concentrated Absorption

- Basics: Multicomponent Absorption

- Software Simulation for Absorption/Stripping Operations (ASPEN PLUS/HYSYS)

----

Please show the love! LIKE, SHARE and SUBSCRIBE!

More likes, sharings, suscribers: MORE VIDEOS!

-----

CONTACT ME

Chemical.Engineering.Guy@Gmail.com

www.ChemicalEngineeringGuy.com

http://facebook.com/Chemical.Engineering.Guy

You speak spanish? Visit my spanish channel -www.youtube.com/ChemEngIQA

Shell and tube heat exchanger design

A very useful presentation about all a engineer needs to know about designing shell and tube heat exchangers.

Astm method for distillation of petroleum products at atmospheric pressure

Facebook Page :https://www.facebook.com/petroleumengineeringz

flow of falling film, transport phenomenon, navier stokes equation derivation

flow of falling film, transport phenomenon, navier stokes equation derivation

What's hot (20)

Aspen HYSYS - Petroleum Assays and Oil Characterization (Slideshare)

Aspen HYSYS - Petroleum Assays and Oil Characterization (Slideshare)

Perry’s Chemical Engineers’ Handbook 7ma Ed Chap 12

Perry’s Chemical Engineers’ Handbook 7ma Ed Chap 12

The Design and Layout of Vertical Thermosyphon Reboilers

The Design and Layout of Vertical Thermosyphon Reboilers

Calculation of an Ammonia Plant Energy Consumption:

Calculation of an Ammonia Plant Energy Consumption:

Gas Absorption & Stripping in Chemical Engineering (Part 2/4)

Gas Absorption & Stripping in Chemical Engineering (Part 2/4)

Astm method for distillation of petroleum products at atmospheric pressure

Astm method for distillation of petroleum products at atmospheric pressure

flow of falling film, transport phenomenon, navier stokes equation derivation

flow of falling film, transport phenomenon, navier stokes equation derivation

Similar to Process Calculation - simple distillation

DESIGN OF AIR PRE HEATER AND ECONOMIZER

Heat/light/electrical energy is out today’s necessity and has scarcity also. Energy conservation is key requirement of any industry at all times.

In general, industries use heat energy for conservation of raw material to finished product. The source of heat energy is generally saturated or super heated steam. The steam generation is common use one boiler with carity of fuels. Whatever may be the fuel the generation should be as economy as possible which adds to the product cost. Further the usage of steam and recycling steam condensate back to boiler is an art depending on plant layouts.

In this project the steam generator is water tube boiler fired with rice husk. The steam is transferred to the tyre/tube moulds where tyres/tubes are cured while the heat is rejected to the tyres the condensate forms and this condensate is put back to the boiler. While doing so the steam is also stopped back to boiler without rejecting complete heat to the product. This gets flashed into atmosphere at feed water tank. The science of separation of condensate from steam saves energy. Better the separation more the fuel conservation.

In the steam generator the fuel is burnt to heat the water and form steam. This fuel burnt flue gas carries lot of energy, out through chimney. Prior to exhausting through the heat left in flue need to be recovered, through heat recovery mechanisms’. In this project an air-preheater condensate heat recovery unit is the major energy consuming station.

Energy Efficiency in Thermal System - Case Studies from Nepal

This presentation was held in the context of DCCI Capacity development Workshop December 2013 in Nepal. For further information go to our website.

Hvac formulas

HOT TOPIC

TON OF REFRIGERATION,

WORK, U FACTOR, LRA (Locked rotor amps)

RPM of motor, HEAT FORMULA, GAS PIPING (Sizing – CF/hr.), CALCULATING OIL NOZZLE SIZE (GPH):

PYTHAGOREAN THEOREM, Linear Measurement Equivalents (U.S. Conventional - SI Metric)

Thermal conductivity admiral

Muhammed Fuad Rashid

Petroleum Engineering Department at Koya University

Heat and Mass Transfer Laboratory

2020

DESIGN OF AIR PRE HEATER AND ECONOMIZER

ABSTRACT

Heat/light/electrical energy is out today’s necessity and has scarcity also. Energy conservation is key requirement of any industry at all times.

In general, industries use heat energy for conservation of raw material to finished product. The source of heat energy is generally saturated or super heated steam. The steam generation is common use one boiler with carity of fuels. Whatever may be the fuel the generation should be as economy as possible which adds to the product cost. Further the usage of steam and recycling steam condensate back to boiler is an art depending on plant layouts.

In this project the steam generator is water tube boiler fired with rice husk. The steam is transferred to the tyre/tube moulds where tyres/tubes are cured while the heat is rejected to the tyres the condensate forms and this condensate is put back to the boiler. While doing so the steam is also stopped back to boiler without rejecting complete heat to the product. This gets flashed into atmosphere at feed water tank. The science of separation of condensate from steam saves energy. Better the separation more the fuel conservation.

In the steam generator the fuel is burnt to heat the water and form steam. This fuel burnt flue gas carries lot of energy, out through chimney. Prior to exhausting through the heat left in flue need to be recovered, through heat recovery mechanisms’. In this project an air-preheater condensate heat recovery unit is the major energy consuming station.

Acutal Cycles and Their Analysis - Unit-I

Air-standard cycles, ideal cycle, fuel-air cycles, actual cycles

Thermal conductivity shushu

Muhammed Fuad Rashid

Petroleum Engineering Department at Koya University

Heat and Mass Transfer Laboratory

2020

FABRICATION OF EXPERIMENTAL SETUP TO EVALUATE CONVECTIVE HEAT TRANSFER COEFFI...

The convective heat transfer through circular depends on the inclination of pipe,Dia of pipe,heat value and insulation provided.

Similar to Process Calculation - simple distillation (20)

Energy Efficiency in Thermal System - Case Studies from Nepal

Energy Efficiency in Thermal System - Case Studies from Nepal

Bidirectional syngas generator TSW work on advanced large scale non steady st...

Bidirectional syngas generator TSW work on advanced large scale non steady st...

FABRICATION OF EXPERIMENTAL SETUP TO EVALUATE CONVECTIVE HEAT TRANSFER COEFFI...

FABRICATION OF EXPERIMENTAL SETUP TO EVALUATE CONVECTIVE HEAT TRANSFER COEFFI...

More from Chandran Udumbasseri

Emulsion and Emulsifiers.pdf

This document explains on emulsion and emulsifiers ad their application in industry. Emulsifiers are used in cosmetic, personal care, pharma preparations, food applications, paints, oilfiled applications, defoamers, agricultural applications and cleaning compositions

Biocides Industrial Application and preparation.pdf

This document describes the industrial application and preparation of biocides.

Metal purification by solvent extraction

This document describes briefly the metal purification by solvent extraction. The extraction of Uranium, Cobal, Nickel, Zinc, etc. are described.

Global market and trends pour point depressants

This document highlights on the global merket position of pour point depressant used in crude oil transportation from drilling wells and also land transportation through pipe lines.

Defoamers and applications

This document gives a brief description on defoamer chemicals used in industry. Foaming is a problem in processing industry like, food, paper and pulp, paint and coating, printing, dyeing, oil drilling, boiler steam production, water treatment, waste management, etc.

Quaternary ammonium compounds marketing and production

The document describes the market potential of quaternary ammonium compounds. Its application as disinfectant for various types of virus, bacteria, fungus and algae. It explains the preparation of benzalkonium chloride, cetyl pyridinium chloride, tallow alkyl dimethyl ammonium chloride,etc. It also explains the formulations as home care,hand wash, wipes, etc..

Production of mea triazine m1

The document is a project report for manufacturing MEA TRIAZINE from paraformaldehyde and monoethanol amine. MEA TRIAZINE is used as H2S scavanger in crude oilfields.

Enhance oil recovery review

This document reviews on parameters that are important while selecting an EOR method

Superabsorbent Market - Application - Production

The document describes the application of super absorbent polymer. It finds use in diapers, female sanitary napkins, agricultural application as water retainer, etc...

Manufacturing pu foam

The document describes the manufacturing procedure, formulation of flexible PU foams, relation of density and durability, etc..

Wax dispersant Wax crystal modifier &; Wax dissolver.

This presentation gives a description on wax dispersant, wax modifier and wax dissolver used in crude oil fields.

Oil sludge treatment m2

Oil sludge is a major source of from oil can be extracted. it contains 40% recoverable oil.This presentation explains treatment methods.

Application of styrene maleic anhydride copolymer

Styrene Maleic Anhydride co polymer is a versatile product that finds application in many industrial use. a brief summary with application is given

More from Chandran Udumbasseri (20)

Biocides Industrial Application and preparation.pdf

Biocides Industrial Application and preparation.pdf

Quaternary ammonium compounds marketing and production

Quaternary ammonium compounds marketing and production

Wax dispersant Wax crystal modifier &; Wax dissolver.

Wax dispersant Wax crystal modifier &; Wax dissolver.

Demulsifiers-water in oil emulsion separation results-m

Demulsifiers-water in oil emulsion separation results-m

Recently uploaded

Connector Corner: Automate dynamic content and events by pushing a button

Here is something new! In our next Connector Corner webinar, we will demonstrate how you can use a single workflow to:

Create a campaign using Mailchimp with merge tags/fields

Send an interactive Slack channel message (using buttons)

Have the message received by managers and peers along with a test email for review

But there’s more:

In a second workflow supporting the same use case, you’ll see:

Your campaign sent to target colleagues for approval

If the “Approve” button is clicked, a Jira/Zendesk ticket is created for the marketing design team

But—if the “Reject” button is pushed, colleagues will be alerted via Slack message

Join us to learn more about this new, human-in-the-loop capability, brought to you by Integration Service connectors.

And...

Speakers:

Akshay Agnihotri, Product Manager

Charlie Greenberg, Host

How world-class product teams are winning in the AI era by CEO and Founder, P...

How world-class product teams are winning in the AI era by CEO and Founder, Product School

GDG Cloud Southlake #33: Boule & Rebala: Effective AppSec in SDLC using Deplo...

Effective Application Security in Software Delivery lifecycle using Deployment Firewall and DBOM

The modern software delivery process (or the CI/CD process) includes many tools, distributed teams, open-source code, and cloud platforms. Constant focus on speed to release software to market, along with the traditional slow and manual security checks has caused gaps in continuous security as an important piece in the software supply chain. Today organizations feel more susceptible to external and internal cyber threats due to the vast attack surface in their applications supply chain and the lack of end-to-end governance and risk management.

The software team must secure its software delivery process to avoid vulnerability and security breaches. This needs to be achieved with existing tool chains and without extensive rework of the delivery processes. This talk will present strategies and techniques for providing visibility into the true risk of the existing vulnerabilities, preventing the introduction of security issues in the software, resolving vulnerabilities in production environments quickly, and capturing the deployment bill of materials (DBOM).

Speakers:

Bob Boule

Robert Boule is a technology enthusiast with PASSION for technology and making things work along with a knack for helping others understand how things work. He comes with around 20 years of solution engineering experience in application security, software continuous delivery, and SaaS platforms. He is known for his dynamic presentations in CI/CD and application security integrated in software delivery lifecycle.

Gopinath Rebala

Gopinath Rebala is the CTO of OpsMx, where he has overall responsibility for the machine learning and data processing architectures for Secure Software Delivery. Gopi also has a strong connection with our customers, leading design and architecture for strategic implementations. Gopi is a frequent speaker and well-known leader in continuous delivery and integrating security into software delivery.

AI for Every Business: Unlocking Your Product's Universal Potential by VP of ...

AI for Every Business: Unlocking Your Product's Universal Potential by VP of Product, Slack

State of ICS and IoT Cyber Threat Landscape Report 2024 preview

The IoT and OT threat landscape report has been prepared by the Threat Research Team at Sectrio using data from Sectrio, cyber threat intelligence farming facilities spread across over 85 cities around the world. In addition, Sectrio also runs AI-based advanced threat and payload engagement facilities that serve as sinks to attract and engage sophisticated threat actors, and newer malware including new variants and latent threats that are at an earlier stage of development.

The latest edition of the OT/ICS and IoT security Threat Landscape Report 2024 also covers:

State of global ICS asset and network exposure

Sectoral targets and attacks as well as the cost of ransom

Global APT activity, AI usage, actor and tactic profiles, and implications

Rise in volumes of AI-powered cyberattacks

Major cyber events in 2024

Malware and malicious payload trends

Cyberattack types and targets

Vulnerability exploit attempts on CVEs

Attacks on counties – USA

Expansion of bot farms – how, where, and why

In-depth analysis of the cyber threat landscape across North America, South America, Europe, APAC, and the Middle East

Why are attacks on smart factories rising?

Cyber risk predictions

Axis of attacks – Europe

Systemic attacks in the Middle East

Download the full report from here:

https://sectrio.com/resources/ot-threat-landscape-reports/sectrio-releases-ot-ics-and-iot-security-threat-landscape-report-2024/

Leading Change strategies and insights for effective change management pdf 1.pdf

Leading Change strategies and insights for effective change management pdf 1.pdf

ODC, Data Fabric and Architecture User Group

Let's dive deeper into the world of ODC! Ricardo Alves (OutSystems) will join us to tell all about the new Data Fabric. After that, Sezen de Bruijn (OutSystems) will get into the details on how to best design a sturdy architecture within ODC.

Neuro-symbolic is not enough, we need neuro-*semantic*

Neuro-symbolic (NeSy) AI is on the rise. However, simply machine learning on just any symbolic structure is not sufficient to really harvest the gains of NeSy. These will only be gained when the symbolic structures have an actual semantics. I give an operational definition of semantics as “predictable inference”.

All of this illustrated with link prediction over knowledge graphs, but the argument is general.

UiPath Test Automation using UiPath Test Suite series, part 4

Welcome to UiPath Test Automation using UiPath Test Suite series part 4. In this session, we will cover Test Manager overview along with SAP heatmap.

The UiPath Test Manager overview with SAP heatmap webinar offers a concise yet comprehensive exploration of the role of a Test Manager within SAP environments, coupled with the utilization of heatmaps for effective testing strategies.

Participants will gain insights into the responsibilities, challenges, and best practices associated with test management in SAP projects. Additionally, the webinar delves into the significance of heatmaps as a visual aid for identifying testing priorities, areas of risk, and resource allocation within SAP landscapes. Through this session, attendees can expect to enhance their understanding of test management principles while learning practical approaches to optimize testing processes in SAP environments using heatmap visualization techniques

What will you get from this session?

1. Insights into SAP testing best practices

2. Heatmap utilization for testing

3. Optimization of testing processes

4. Demo

Topics covered:

Execution from the test manager

Orchestrator execution result

Defect reporting

SAP heatmap example with demo

Speaker:

Deepak Rai, Automation Practice Lead, Boundaryless Group and UiPath MVP

The Art of the Pitch: WordPress Relationships and Sales

Clients don’t know what they don’t know. What web solutions are right for them? How does WordPress come into the picture? How do you make sure you understand scope and timeline? What do you do if sometime changes?

All these questions and more will be explored as we talk about matching clients’ needs with what your agency offers without pulling teeth or pulling your hair out. Practical tips, and strategies for successful relationship building that leads to closing the deal.

GenAISummit 2024 May 28 Sri Ambati Keynote: AGI Belongs to The Community in O...

“AGI should be open source and in the public domain at the service of humanity and the planet.”

Software Delivery At the Speed of AI: Inflectra Invests In AI-Powered Quality

In this insightful webinar, Inflectra explores how artificial intelligence (AI) is transforming software development and testing. Discover how AI-powered tools are revolutionizing every stage of the software development lifecycle (SDLC), from design and prototyping to testing, deployment, and monitoring.

Learn about:

• The Future of Testing: How AI is shifting testing towards verification, analysis, and higher-level skills, while reducing repetitive tasks.

• Test Automation: How AI-powered test case generation, optimization, and self-healing tests are making testing more efficient and effective.

• Visual Testing: Explore the emerging capabilities of AI in visual testing and how it's set to revolutionize UI verification.

• Inflectra's AI Solutions: See demonstrations of Inflectra's cutting-edge AI tools like the ChatGPT plugin and Azure Open AI platform, designed to streamline your testing process.

Whether you're a developer, tester, or QA professional, this webinar will give you valuable insights into how AI is shaping the future of software delivery.

LF Energy Webinar: Electrical Grid Modelling and Simulation Through PowSyBl -...

Do you want to learn how to model and simulate an electrical network from scratch in under an hour?

Then welcome to this PowSyBl workshop, hosted by Rte, the French Transmission System Operator (TSO)!

During the webinar, you will discover the PowSyBl ecosystem as well as handle and study an electrical network through an interactive Python notebook.

PowSyBl is an open source project hosted by LF Energy, which offers a comprehensive set of features for electrical grid modelling and simulation. Among other advanced features, PowSyBl provides:

- A fully editable and extendable library for grid component modelling;

- Visualization tools to display your network;

- Grid simulation tools, such as power flows, security analyses (with or without remedial actions) and sensitivity analyses;

The framework is mostly written in Java, with a Python binding so that Python developers can access PowSyBl functionalities as well.

What you will learn during the webinar:

- For beginners: discover PowSyBl's functionalities through a quick general presentation and the notebook, without needing any expert coding skills;

- For advanced developers: master the skills to efficiently apply PowSyBl functionalities to your real-world scenarios.

DevOps and Testing slides at DASA Connect

My and Rik Marselis slides at 30.5.2024 DASA Connect conference. We discuss about what is testing, then what is agile testing and finally what is Testing in DevOps. Finally we had lovely workshop with the participants trying to find out different ways to think about quality and testing in different parts of the DevOps infinity loop.

Assuring Contact Center Experiences for Your Customers With ThousandEyes

Presented by Suzanne Phillips and Alex Marcotte

Builder.ai Founder Sachin Dev Duggal's Strategic Approach to Create an Innova...

In today's fast-changing business world, Companies that adapt and embrace new ideas often need help to keep up with the competition. However, fostering a culture of innovation takes much work. It takes vision, leadership and willingness to take risks in the right proportion. Sachin Dev Duggal, co-founder of Builder.ai, has perfected the art of this balance, creating a company culture where creativity and growth are nurtured at each stage.

Slack (or Teams) Automation for Bonterra Impact Management (fka Social Soluti...

Sidekick Solutions uses Bonterra Impact Management (fka Social Solutions Apricot) and automation solutions to integrate data for business workflows.

We believe integration and automation are essential to user experience and the promise of efficient work through technology. Automation is the critical ingredient to realizing that full vision. We develop integration products and services for Bonterra Case Management software to support the deployment of automations for a variety of use cases.

This video focuses on the notifications, alerts, and approval requests using Slack for Bonterra Impact Management. The solutions covered in this webinar can also be deployed for Microsoft Teams.

Interested in deploying notification automations for Bonterra Impact Management? Contact us at sales@sidekicksolutionsllc.com to discuss next steps.

Empowering NextGen Mobility via Large Action Model Infrastructure (LAMI): pav...

Empowering NextGen Mobility via Large Action Model Infrastructure (LAMI)

Recently uploaded (20)

Connector Corner: Automate dynamic content and events by pushing a button

Connector Corner: Automate dynamic content and events by pushing a button

How world-class product teams are winning in the AI era by CEO and Founder, P...

How world-class product teams are winning in the AI era by CEO and Founder, P...

GDG Cloud Southlake #33: Boule & Rebala: Effective AppSec in SDLC using Deplo...

GDG Cloud Southlake #33: Boule & Rebala: Effective AppSec in SDLC using Deplo...

FIDO Alliance Osaka Seminar: Passkeys at Amazon.pdf

FIDO Alliance Osaka Seminar: Passkeys at Amazon.pdf

AI for Every Business: Unlocking Your Product's Universal Potential by VP of ...

AI for Every Business: Unlocking Your Product's Universal Potential by VP of ...

State of ICS and IoT Cyber Threat Landscape Report 2024 preview

State of ICS and IoT Cyber Threat Landscape Report 2024 preview

Leading Change strategies and insights for effective change management pdf 1.pdf

Leading Change strategies and insights for effective change management pdf 1.pdf

Neuro-symbolic is not enough, we need neuro-*semantic*

Neuro-symbolic is not enough, we need neuro-*semantic*

UiPath Test Automation using UiPath Test Suite series, part 4

UiPath Test Automation using UiPath Test Suite series, part 4

The Art of the Pitch: WordPress Relationships and Sales

The Art of the Pitch: WordPress Relationships and Sales

GenAISummit 2024 May 28 Sri Ambati Keynote: AGI Belongs to The Community in O...

GenAISummit 2024 May 28 Sri Ambati Keynote: AGI Belongs to The Community in O...

Software Delivery At the Speed of AI: Inflectra Invests In AI-Powered Quality

Software Delivery At the Speed of AI: Inflectra Invests In AI-Powered Quality

LF Energy Webinar: Electrical Grid Modelling and Simulation Through PowSyBl -...

LF Energy Webinar: Electrical Grid Modelling and Simulation Through PowSyBl -...

Assuring Contact Center Experiences for Your Customers With ThousandEyes

Assuring Contact Center Experiences for Your Customers With ThousandEyes

Builder.ai Founder Sachin Dev Duggal's Strategic Approach to Create an Innova...

Builder.ai Founder Sachin Dev Duggal's Strategic Approach to Create an Innova...

Slack (or Teams) Automation for Bonterra Impact Management (fka Social Soluti...

Slack (or Teams) Automation for Bonterra Impact Management (fka Social Soluti...

Empowering NextGen Mobility via Large Action Model Infrastructure (LAMI): pav...

Empowering NextGen Mobility via Large Action Model Infrastructure (LAMI): pav...

FIDO Alliance Osaka Seminar: Passkeys and the Road Ahead.pdf

FIDO Alliance Osaka Seminar: Passkeys and the Road Ahead.pdf

Process Calculation - simple distillation

- 1. Process Calculation: Simple Distillation Chandran Udumbasseri Technical Consultant chandran.udumbasseri@gmail.com. Part !: Rate of distillation & Vapor Column size When a product is developed at laboratory scale the next step is pilot plant trial and finally bulk trial. A reaction can be conducted with its limitations but the separation and purification are the difficult and expensive step in any process. Bulk trials can be started once the plant is erected. After pilot plant trial it is necessary to calculate all parameters required for designing the vessel, column and condensers As an example distillation is taken for calculating parameters. Tri ethyl amine distillation is taken for parameter calculation. This can help to understand step by step process calculation To calculate rate of distillation, total heat exchange area has to be found out. A reactor has a cylindrical body with two tori spherical bottom and top dished ends. Usually the occupancy volume of the material is cylindrical body with bottom tori spherical dished end. The total heat transfer takes place on the surface of cylindrical body and tori spherical surface of the bottom dished end Surface area Surface area of the cylindrical part =πDh, D is the diameter of the cylinder and ‘h’ is the height of the cylinder. Surface area of tori-spherical dish Total surface area

- 2. The height to diameter ratio is 1.5 So D = h/1.5 πDh = πD2 /1.5 Example: Reactor volume =10000 liter Occupancy = 75% Occupancy volume = 10000x0.75 = 7,500 litters = π(D2 /4)x1.5D + (π/24)xD3 = [(1.5/4) +(1/24)]x π x D3 =0.4167x π x D3 =7500x1000cm3 =1.308 D3 D3 =5733944.95 D = 178.985cm= 1.79m Total surface area = 3,14x1.79x1.5x1.79 + (3.14/4)x(1.147x1.79)2 =15.091 + 3.309 = 18.4 sq m Rate of distillation To illustrate, the distillation of triethyl amine under atmospheric pressure and using steam as heating transfer utility is studied.

- 3. The reactor has a capacity of 10,000 lts (10KL). The material of construction (MOC) is SS316. The working capacity is taken as 7.5KL. it has a Heat transfer area of 18.4sq m. The heat energy transferred heating area; 18.4 sq m is calculated using the formula Q = UxAx (t2-t1) U = overall heat transfer coefficient A = 18.4 sq m t2 – t1 = 89-25 = 64 The value for U may be assumed as = 250 Kcal/Sq m /hr/K (metal of construction, SS316) Utility (steam) Temparature (incoming,) o C,T1 100 o F 212 Utility (ateam) Temparature (outlet) o C, T2 100 o F 212 Initial material temperature, o C, t1 25 Final material temperature, o C ,t2 89 Q = 250 (Kcal/Sq m /hr/K)x18.4(sq m) x 64 (o C) = 294400 Kcal/hr The material is heated from 25o C to 89o C (to the BP) and this is sensible heat. The hot liquid needs to be vaporised at constant temperature 89o C. This is latent heat Total heat required to vaporise = mass x latent Latent heat of TEA = 82.61 Kcal/Kg K Total latent heat = mass of vaporKg x 82.61 Kcal/Kg K

- 4. Total sensible heat = Mass of material x Heat capacity x (t2-t1) Mass of material = occupancy volume x density = 7500 x 0.7255 Heat capacity = 0.51086 Kcal/Kg K t2- t1 = 89-25 = 64 Sensible heat = 7500 x 0.7255 Kg x 0.51086 Kcal/Kg K x 64 = 177901.886 Kcal Total heat load of the material = sensible heat + latent heat 294400 Kcal/hr = 177901.886 Kcal + mass of vapour Kg x 82.61 Kcal/Kg K Mass of vapour, Kg = (294400 Kcal/hr - 177901.886 Kcal)/ 82.61 Kcal/Kg K 1410.218Kg/hr Rate of vaporization/distillation = 1410.218Kg/hr Vapour column size Column diameter Clausius-Clapeyron equation is used to find vapor pressure of the boiled up vapor from the still p1 = vapor pressure at T1

- 5. p2 = vapor pressure at T2 P can be in mm of Hg, Atm, etc T is in Kelvin ΔH = enthalpy of vaporisation, KJ/mol R = 8.314 JKmol Input data P1 = 1atm P2 = ? T1 = 273 +25 = 298K T2 = 273 + 89 = 362K ΔH = 35 KJ/mol P2 = 1.0025atm = 1.0025x750 = 763mm of Hg Now calculating vapour volume usingideal gas law PV = nRt V = nRT/P Boil-up = 1410Kg/hr Mol weight = 101.19 T = 362K P = 1.0025atm V = 41832Lt/hr

- 6. = 41.832m3 /hr = 42.832/3600 = 0.01162m3 /sec Souders-Brown equation is used to calculate vapour velocity and cross area v = vapour velocity, m/s tl = liquid density, kg/m3 rv = vapour density, kg/m3 Vapour velocity = 1.53m/s The cross area is given by the following formula D = 0.0982m =0.0982x3.281 = 0.3222 x12 = 3.866 inch Diameter of the column is = ~ 4” (Inches) Height of the column The vapour pressure is calculated above using Clausius-Clapeyron equation, as P = 763mm

- 7. But P = hxdxg h = height d = vapour density, Kg/m3 = 3.5Kg/m3 g = 9.81m/s2 1mm = 133.322Pa h = P/dg =2.96m = 2.95x3.281 ft= 9.71ft The height of the vapour column is ~ 10 ft Data Used The above calculations are based on the following books. The below data are collected from books like PROCESS HEAT TRANSFER: Donald Kern Chemical Process Equipment: James Couper, Rony Penney, etc Chemical Engineering design: Richardson & Coulson Overall heat transfer coefficient for metal pipes Type Application Overall heat transfer coefficient, U W/m2 /K Btu/ft2 /F Tubular heating/cooling Gas at atmospheric pressure inside and outside 5-15 1-0 Gas at high pressure inside and outside 150-500 25-90 Liquid inside and gas outside vice versa 15-70 3-15 Gas at high pressure inside and liquid outside 200-400 15-70

- 8. Liquid inside and outside 150-1200 25-200 Steam outside and liquid inside 300-1200 50-200 Condensation Organic vapour outside/cooling water (CW) inside 300-1200 50-200 Tubular evaporation Steam outside/high viscous liquid inside 300-900 50-150 Steam outside/low viscous liquid inside 600-1700 100-300 Steam outside/liquid inside forced circulation 700-3000 150-300 Air cooled exchanger CW 600-700 100-130 Cooling lighr hydrocarbon 400-500 70-95 Cooling of tar 30-60 5-10 Cooling ofair/flue gas 60-100 10-20 Cooling of hydrocarbon gas 200-400 35-50 Condensation of low pressure steam 700-800 125-150 Condensation of organic vapour 250-500 65-90 Plate heat exchanger Liquid to liquid 1000- 4000 150-700 Data of Triethyl amine Tri ethyl amine Molecular weight,g/mol 101.18 Density g/ml 0.7255 Kg/Cu m 725.5 Lb/cu ft 45.2915 Vapour Density, Kg/m3 3.5 Heat capacity, J/mol/K 216.43 BTU/lbmol 93.0478 Kcal/Kg K 0.51086 Latent Heat of Vaporization, KJ/mol 35 Kcal/Kg K 82.613 Btu/lb 148.604

- 9. Viscosity , cP/Kpas 0.363 KPas 0.363 lb/ft-sec 0.24395 Steam Utility Temparature (incoming,)C 100 o F 212 Utility Temparature (outlet)C 100 o F 212 Specific heat,( at 100C), KJ/Kg 4.18 Kcal/Kg.K 1 Latent Heat of steam at 1atm, KJ/kg 2257 Kcal/Kg 539.952 Part II: Condenser/Shell and Tube Heat Exchanger (Next Issue)