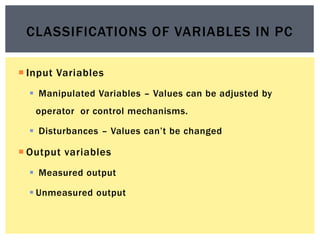

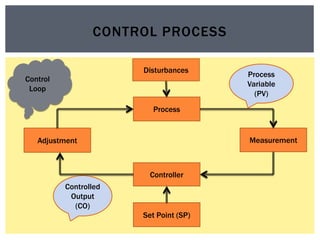

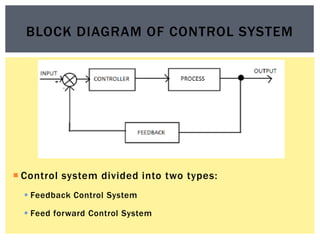

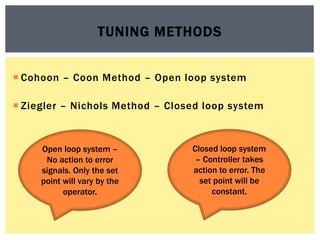

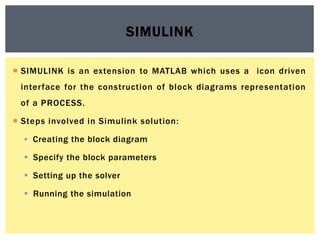

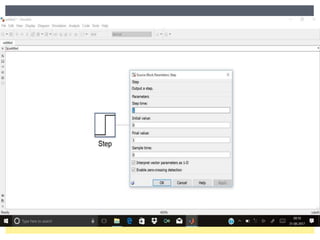

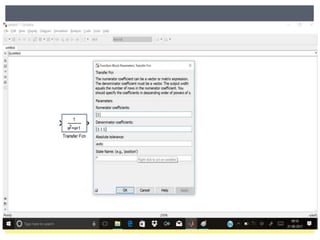

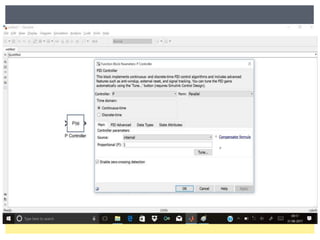

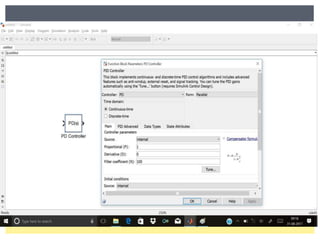

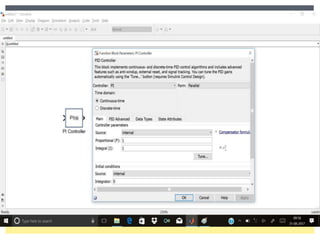

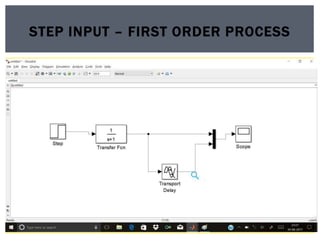

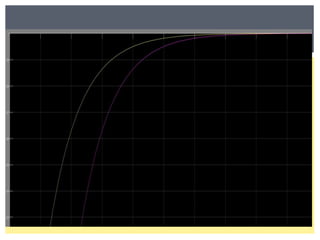

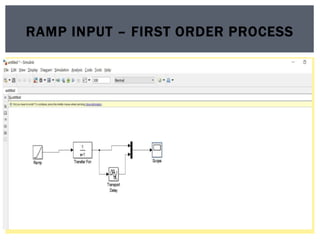

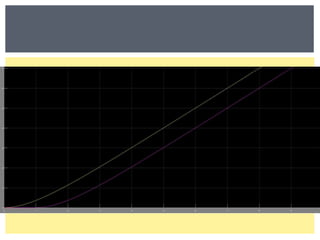

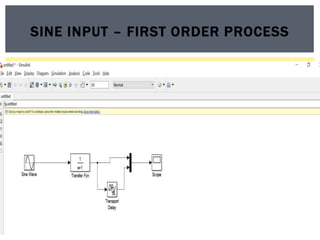

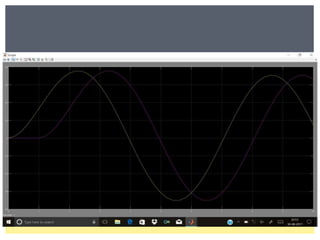

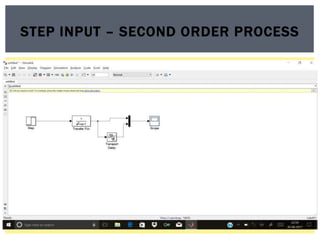

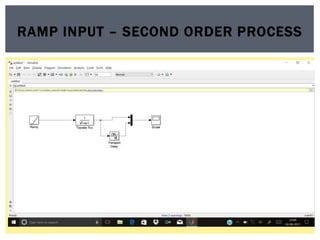

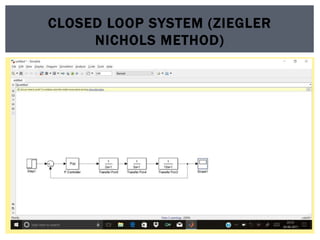

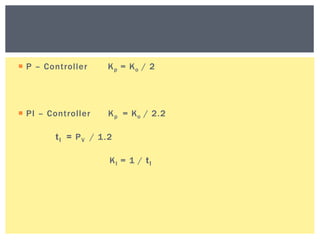

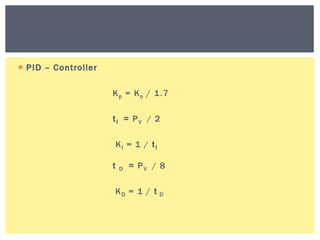

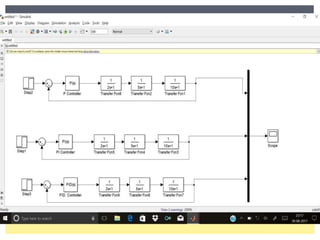

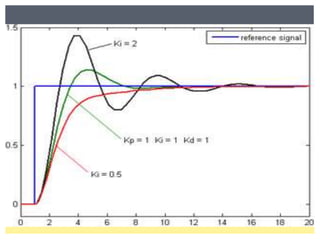

The document outlines a workshop presented by Lakshmipriya J on process control in chemical engineering using MATLAB and Simulink. It covers the fundamentals of process control, the need for control systems in chemical plants, the types of processes (discrete, batch, and continuous), and various methods for controller tuning. Additionally, it introduces MATLAB as a tool for numerical experiments and Simulink for block diagram representation of processes.