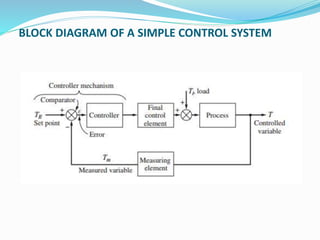

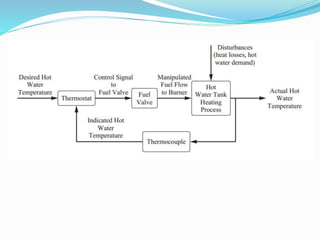

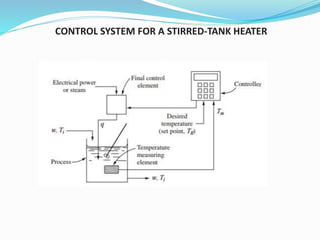

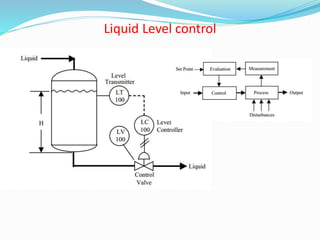

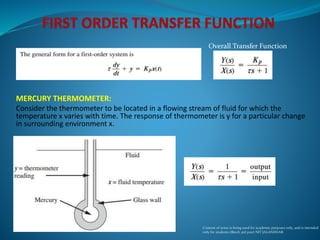

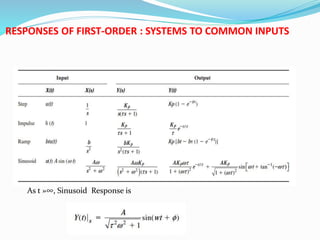

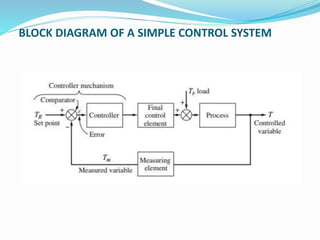

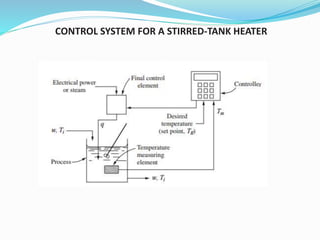

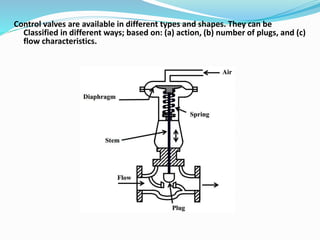

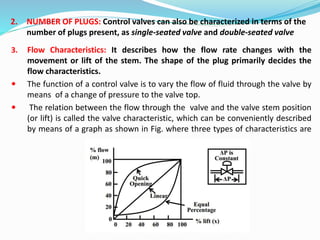

This document discusses process control systems and their components. It describes the main goals of process control as enhancing safety, satisfying environmental constraints, meeting quality specifications, efficiently using resources, and increasing profitability. The key components of a control system are identified as the process, measuring element, controller, and final control element. A block diagram shows a simple closed-loop control system with feedback. Common control system terms are defined, such as deviation variable, error, set point, and negative feedback. Examples of controlled processes include a stirred-tank heater and liquid level control.