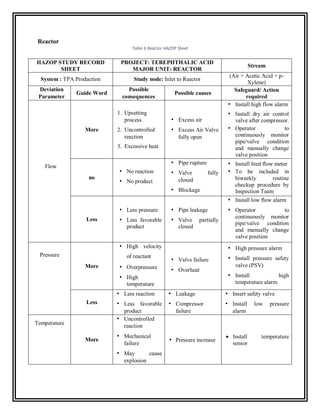

1. The document describes HAZOP (Hazard and Operability) studies conducted on various units in a terephthalic acid production plant, including the reactor, crystallizer, scrubber, and dryer.

2. For each unit, potential deviations in parameters like flow, pressure, and temperature are identified along with their possible consequences and causes.

3. Safeguards and required actions are recommended to address the deviations, such as installing alarms, safety valves, temperature sensors, and implementing monitoring and inspection procedures.