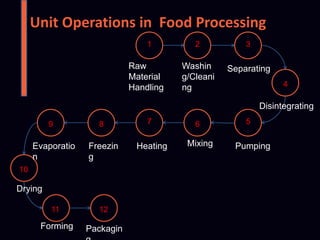

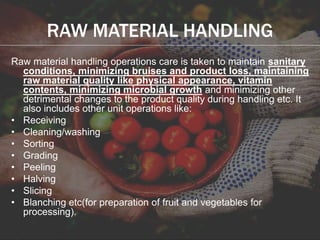

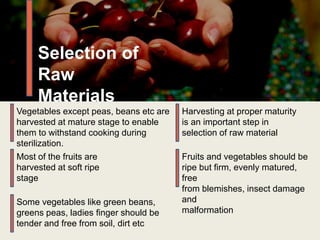

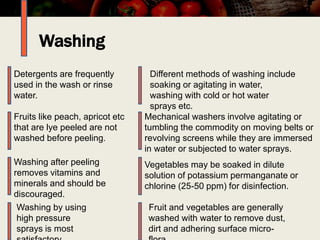

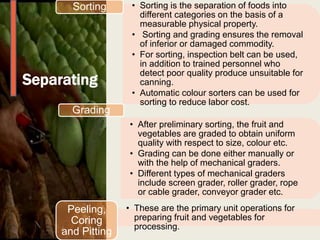

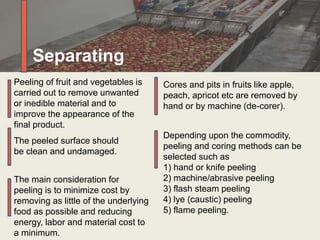

The document outlines the unit operations involved in food processing, focusing on the handling, washing, and separating of raw materials like fruits and vegetables. It details methods for maintaining product quality during harvesting, cleaning procedures, and the importance of sorting and grading for ensuring food safety and uniformity. Various mechanical and manual techniques for peeling, coring, and pitting are also discussed to optimize processing efficiency.