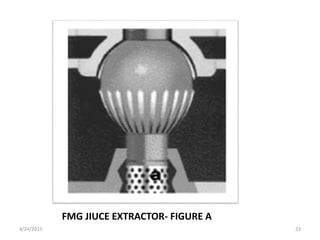

The document details the global trade and manufacturing processes of fruit juices, highlighting the significance of apples and oranges as leading fruit commodities. It outlines the various processing stages including juice extraction, clarification, and concentration techniques, alongside methods for washing, grading, and testing fruits. The use of enzymes in juice production to enhance extraction and clarification is emphasized, along with the importance of filtration for removing insoluble solids.