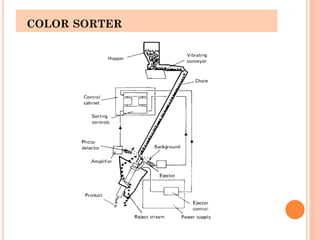

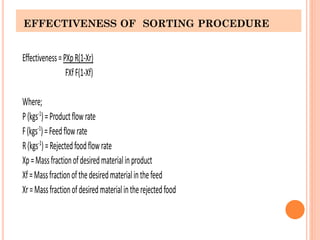

Sorting separates foods based on a single measurable property like size, weight, or color. Grading assesses overall quality using multiple attributes and properties. Both operations upgrade products. Common sorting methods include weight, size, shape, density, and color sorting using sensors, cameras and machines. Grading requires human or trained assessment of quality factors like appearance, defects, and standards. It assigns foods to quality categories while sorting separates based on a single criterion.