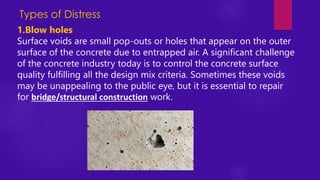

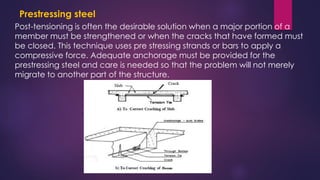

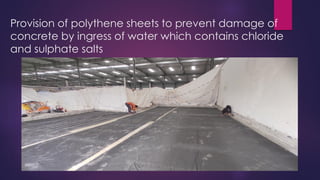

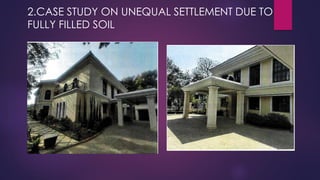

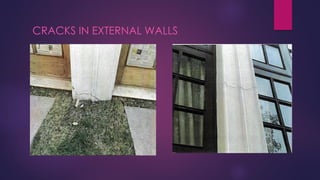

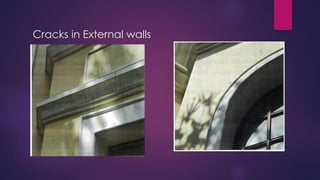

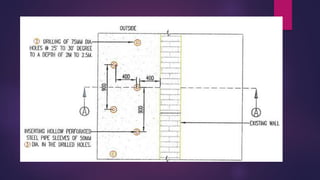

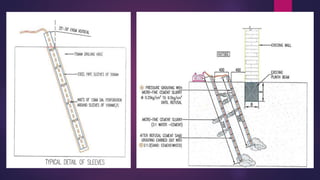

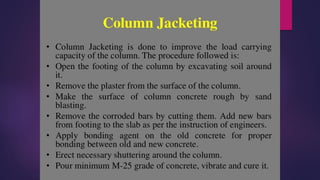

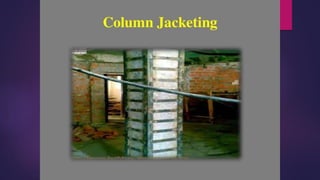

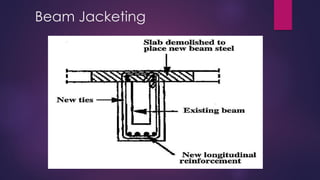

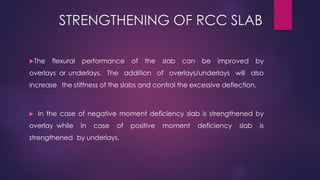

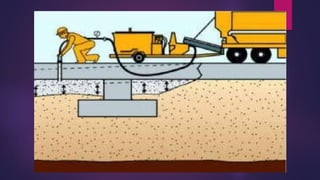

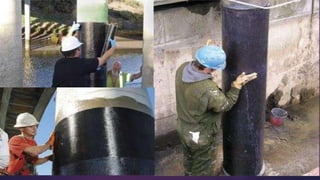

This document discusses repair, restoration, and retrofitting of structures. It defines key terms like repair, restoration, rehabilitation, and retrofitting. It describes common types of structural distress like cracking, corrosion, settlement, and provides examples of repair techniques. Case studies are presented on repairing industrial structures affected by differential settlement through soil excavation and replacement, and strengthening of slabs through jacketing and overlays. Basic retrofitting techniques like beam jacketing are also introduced.