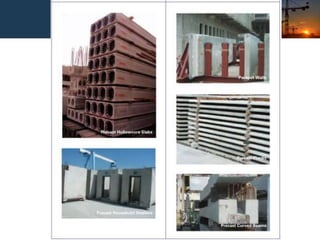

This document provides an overview of prefabricated structures. It defines prefabrication as assembling components of a structure in a factory and transporting them to the construction site. Key points include:

- Prefabrication offers benefits like faster construction, improved quality control, and reduced waste.

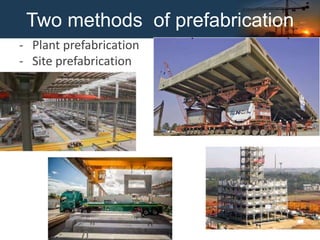

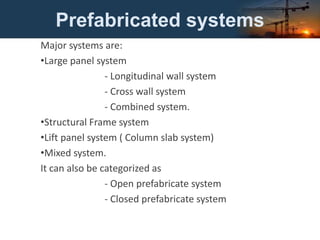

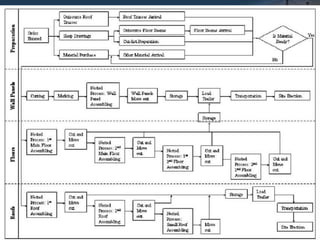

- There are different methods of prefabrication including plant and site prefabrication. Systems can be classified by size and degree of prefabrication.

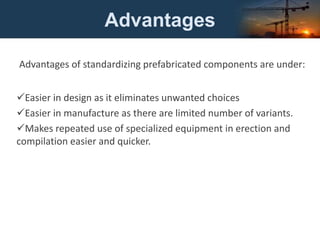

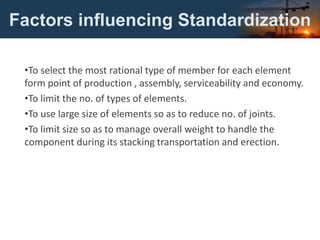

- Standardization of components improves design, manufacturing and construction.

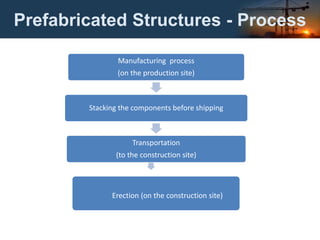

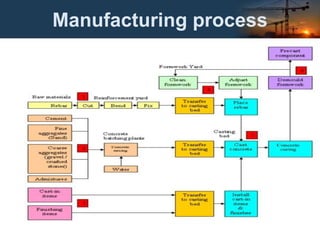

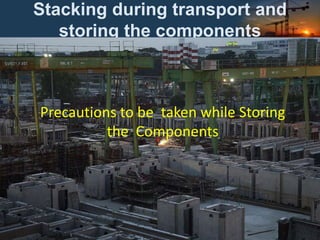

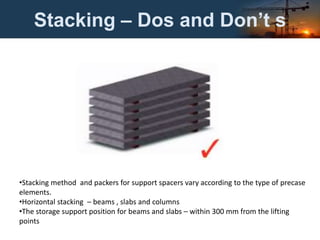

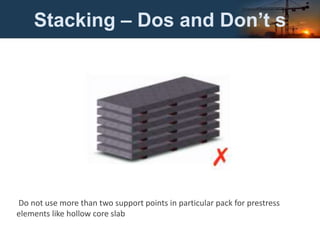

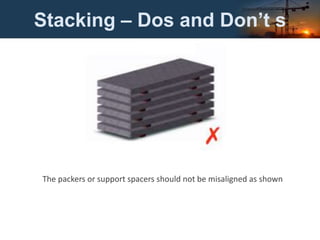

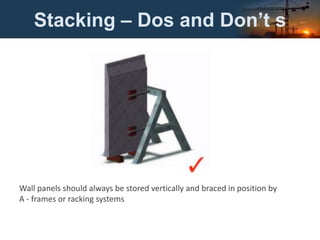

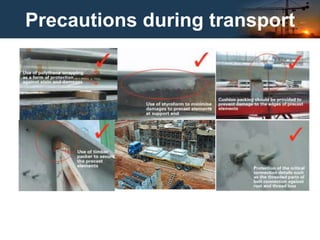

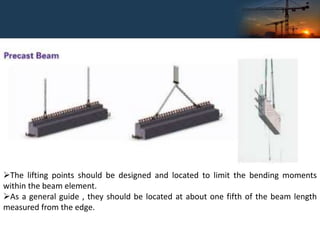

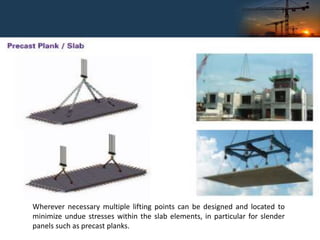

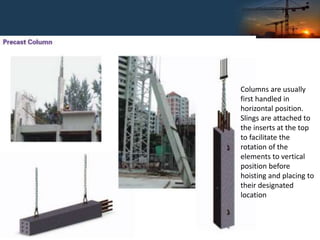

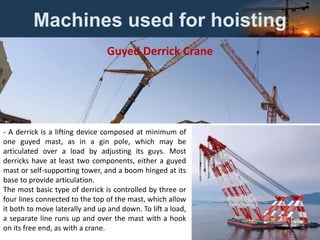

- The prefabrication process involves manufacturing components, stacking, transportation, and erecting them on-site using cranes or other machinery.