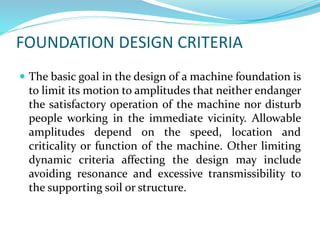

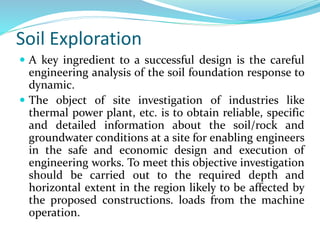

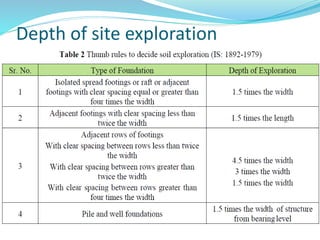

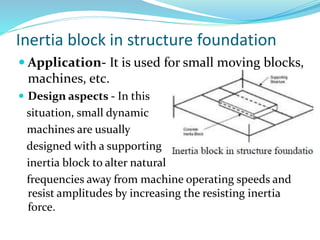

This document presents a literature review and overview of machine foundation design for a civil engineering course project. It discusses the increasing vibrations caused by advancing machinery technology. Various types of machine foundations are described, including block, box, spring mounted block, combined block, tabletop, tabletop with isolator, inertia block in structure, and pile supported foundations. Foundation design criteria aim to limit motion amplitudes. Soil exploration is important to understand foundation response to dynamic loads. Depth of site exploration should be sufficient. In conclusion, thermal power plants require extensive foundation studies due to heavy equipment, and foundation issues cause about 19% of equipment problems annually.

![LITERATURE REVIEW

Gazetas G. (1983) [1], Prakash S. et al.[2], Wang ZY et

al.[3] and Srinivasulu P. et al.[15] found that with the

advancement of technology and literature available in

the field of industry, high speed machinery has been

developed. As the speed of machinery have increased,

vibrations effect increased adversely affecting the

condition of equipment.

Various machine foundations, applications and

their design aspects are discussed forward.](https://image.slidesharecdn.com/machinefoundationppt-210429101625/85/Machine-foundation-4-320.jpg)

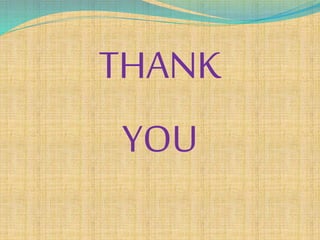

![Block foundation

Application- It is used for machines of large mass and a

small natural frequency

Design aspects - The ability

to use block foundation

primarily depends on the

quality of near surface soils

and designed as rigid

structures.

The dynamic response of a rigid block foundation

depends only on the dynamic load, foundation‘s mass,

dimensions, and soil characteristics observed by

Pradhan P.K. et al. [5]](https://image.slidesharecdn.com/machinefoundationppt-210429101625/85/Machine-foundation-5-320.jpg)

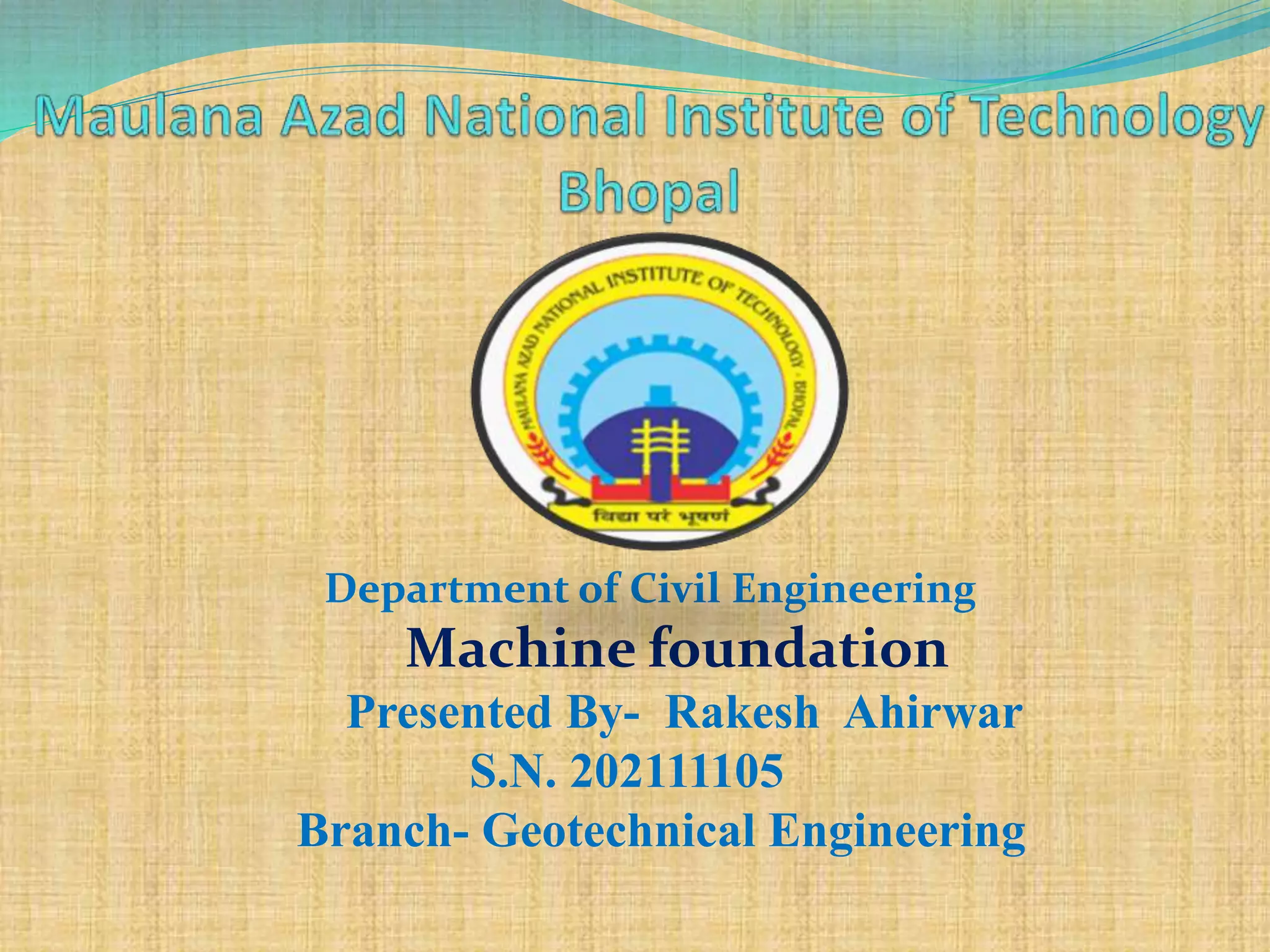

![Tabletop with isolator foundation

Application- It is used for high vibrating machines like

pumps, blowers, fans, etc

Design aspects - Springs and

dampers located at the top of

supporting columns are

sometimes used to minimize

the response to dynamic loading.

The effectiveness of isolators depends on the machine

speed and frequency by Richart Jr. et al. [17].](https://image.slidesharecdn.com/machinefoundationppt-210429101625/85/Machine-foundation-10-320.jpg)

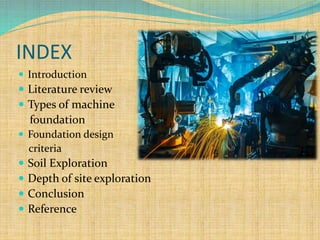

![Pile supported foundation

Application- It is used in soft ground conditions and

excessive Settlement e.g. drilled piers, auger cast piles,

and driven piles.

Design aspects - Any of the

previously mentioned

foundation types may be

supported directly on soil

or on piles. Piles use end

bearing, frictional side adhesion, or a combination of

both to transfer axial loads into the underlying soil

noted by Kaynia A.M. et al. [6].](https://image.slidesharecdn.com/machinefoundationppt-210429101625/85/Machine-foundation-12-320.jpg)