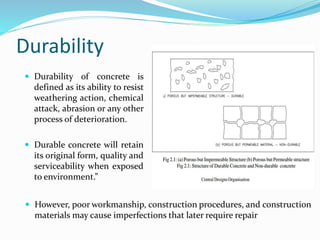

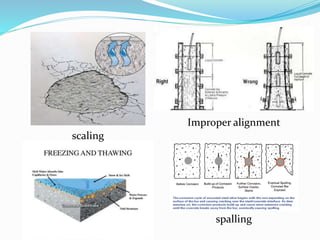

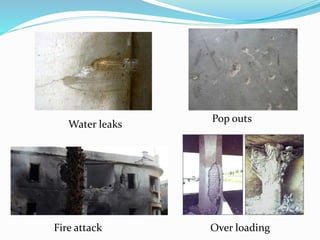

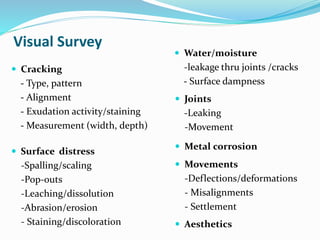

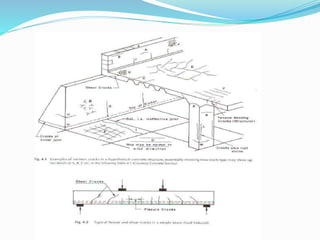

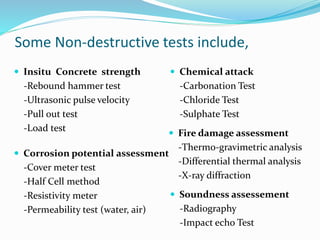

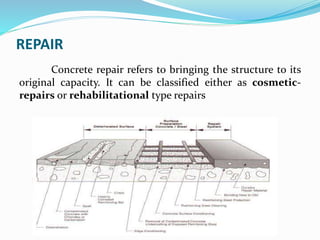

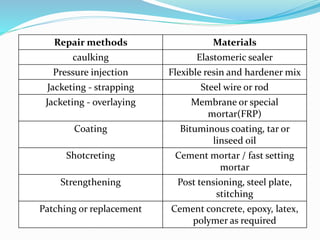

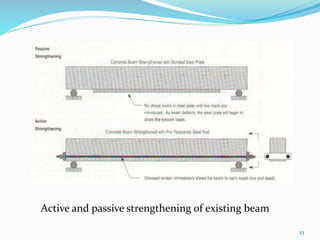

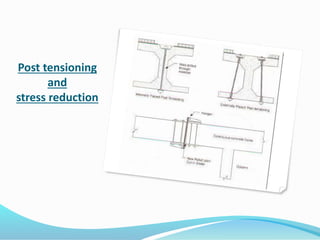

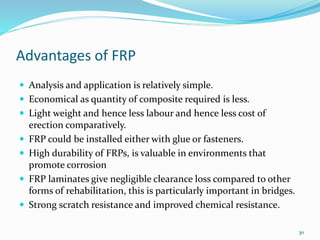

The document discusses the repair of damaged concrete structures. It begins by explaining the importance of cement concrete and factors that can cause damage like poor workmanship, construction procedures, and materials. Common types of damage include cracking, spalling, scaling, and corrosion. A proper evaluation involves visual inspection, detailed crack mapping, non-destructive testing, and instrumentation. Common repair methods include patching, overlays, jacketing, shotcrete, and strengthening techniques like FRP. For a successful repair, it is important to select compatible materials, properly prepare the surface, and ensure continuity with the existing structure.