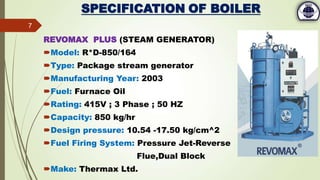

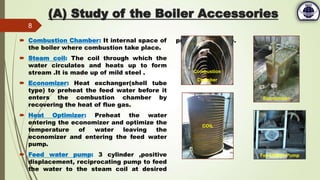

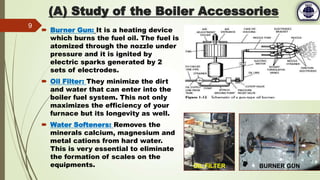

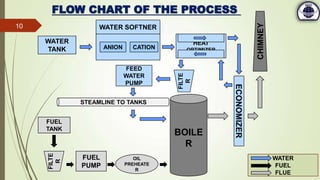

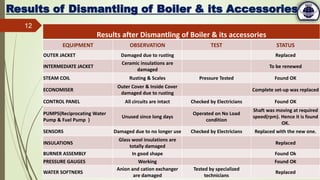

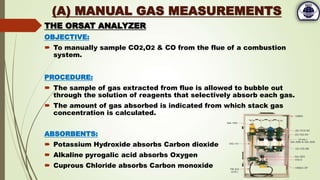

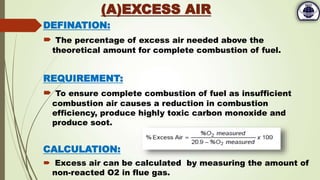

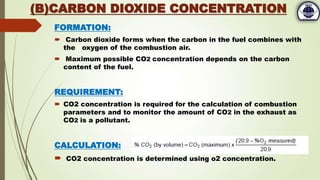

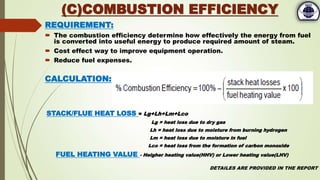

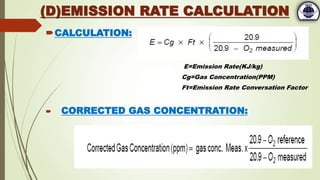

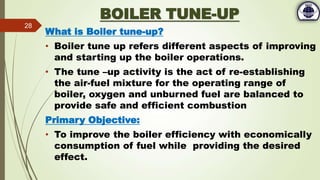

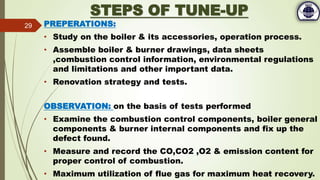

This document presents a case study and methods to re-establish a condemned boiler. It includes an introduction, contents listing, acknowledgements, abstract on the Hindustan Storage & Distribution Company where the boiler is located, specifications and diagrams of the boiler, scope of dismantling and repair work, results of dismantling, scope of work after renovation including flue gas analysis and boiler tuning.