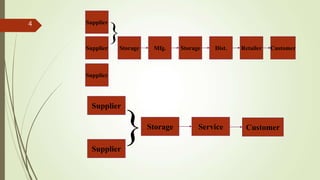

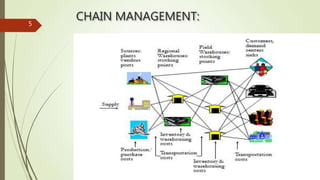

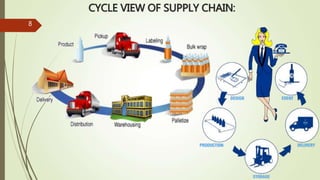

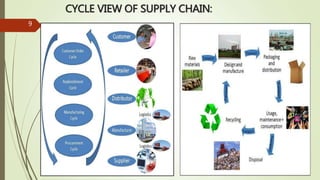

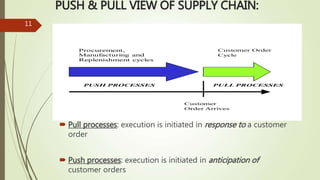

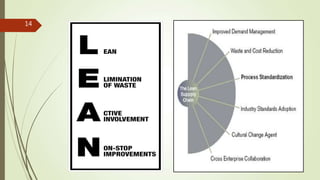

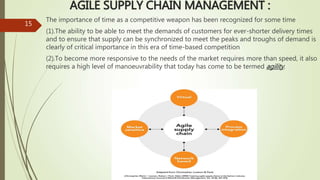

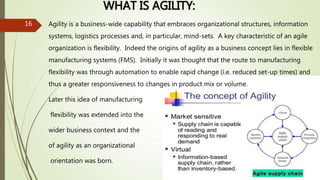

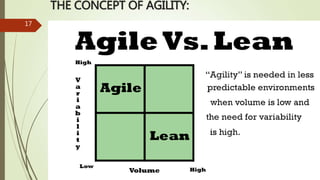

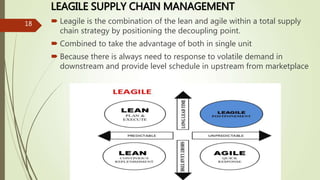

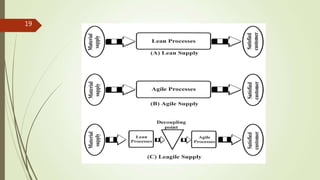

This document presents information on supply chain management in the automobile industry. It begins with an introduction to supply chain management and its importance. It then discusses lean, agile, and leagile supply chain management approaches. Lean focuses on eliminating waste, synchronizing flow, and collaborative relationships. Agile aims for flexibility and responsiveness. Leagile combines lean and agile approaches. The document concludes that effective supply chain management is important for automakers to reduce costs and ensure high quality, on-time delivery of products to customers.