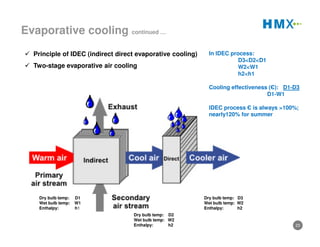

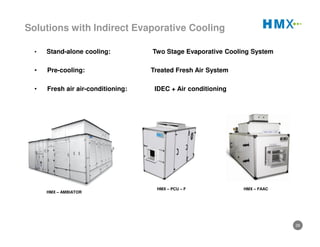

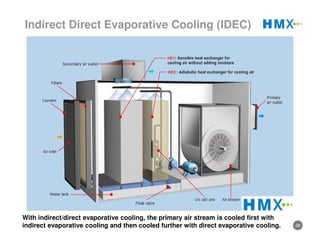

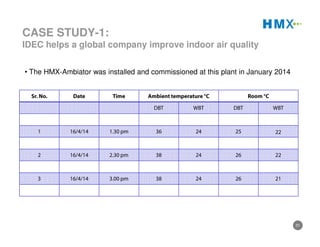

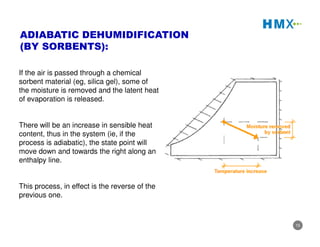

The document discusses innovative cooling solutions, particularly focusing on indirect evaporative cooling (IEC) technology, which provides efficient and eco-friendly cooling for industrial and commercial applications. It includes case studies demonstrating the effectiveness of IEC in improving indoor air quality and comfort in various environments, as well as outlines the advantages of different cooling technologies offered by a.t.e. enterprises. Additionally, it highlights the importance of comfort conditioning for human well-being, emphasizing factors such as temperature and humidity.

![16

If two air streams are

mixed, having:

-mass flow rates m1 and m2,

-dry bulb temperatures t1and t2,

-enthalpies H1and H2,

the result will be:

m1t1 + m2t2 = [m1 + m2]t3,

m1H1 + m2H2 = [m1 + m2]H3

Therefore:

t3 = (m1t1 + m2t2) / m1 + m2

H3 = (m1H1 + m2H2) / m1 + m2

MIXING:

The psychrometric chart can be used to establish the value of t3 and H3. The two

state points are connected by a straight line, which is then divided in inverse

proportions of m1 and m2. If the mass flow rate m1 is the greater, the resulting point

P will represent the state of the combined air stream.](https://image.slidesharecdn.com/indirectevaporativecooling-doha12thsep2015-160301060319/85/Indirect-Evaporative-Cooling-16-320.jpg)