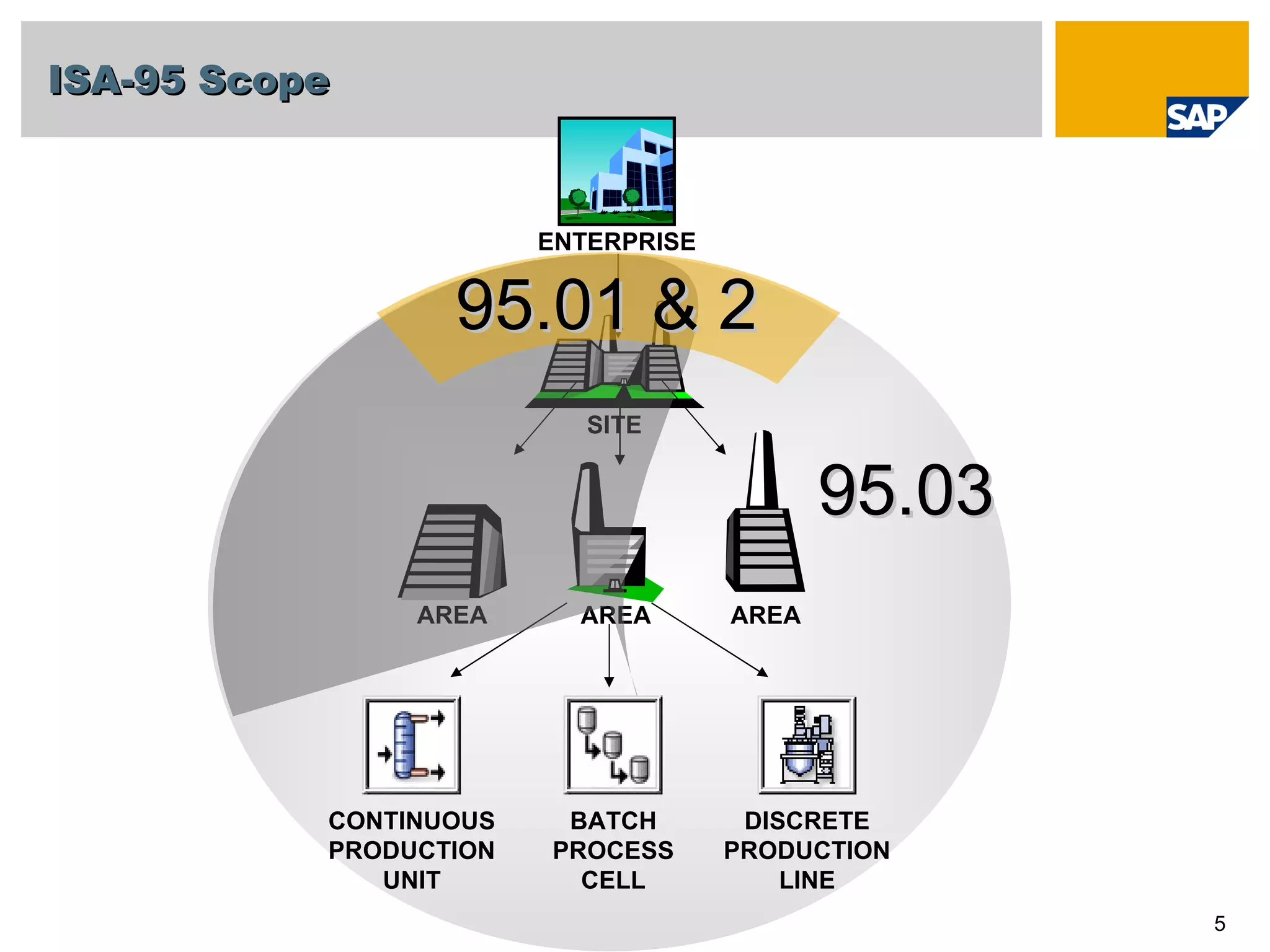

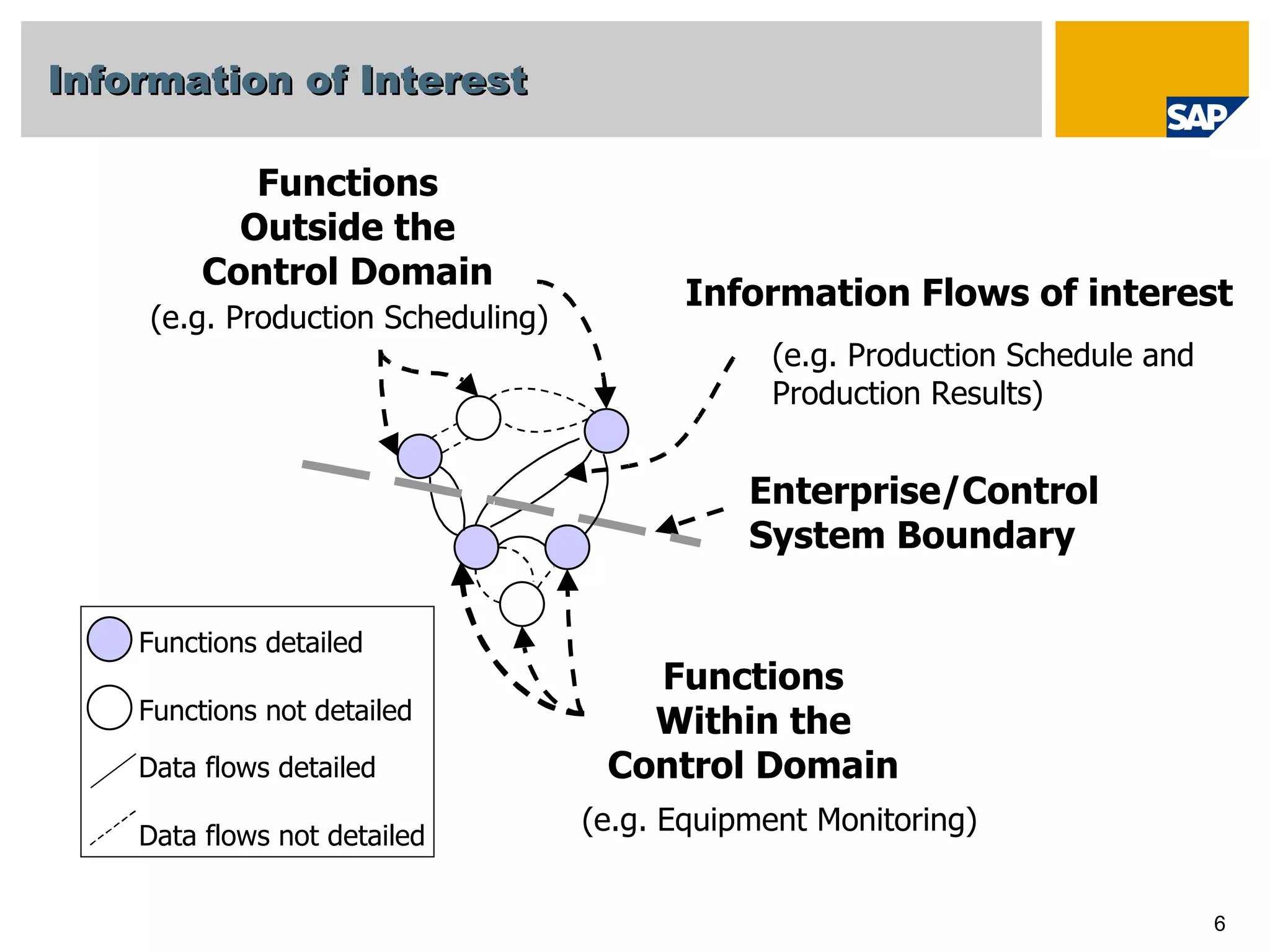

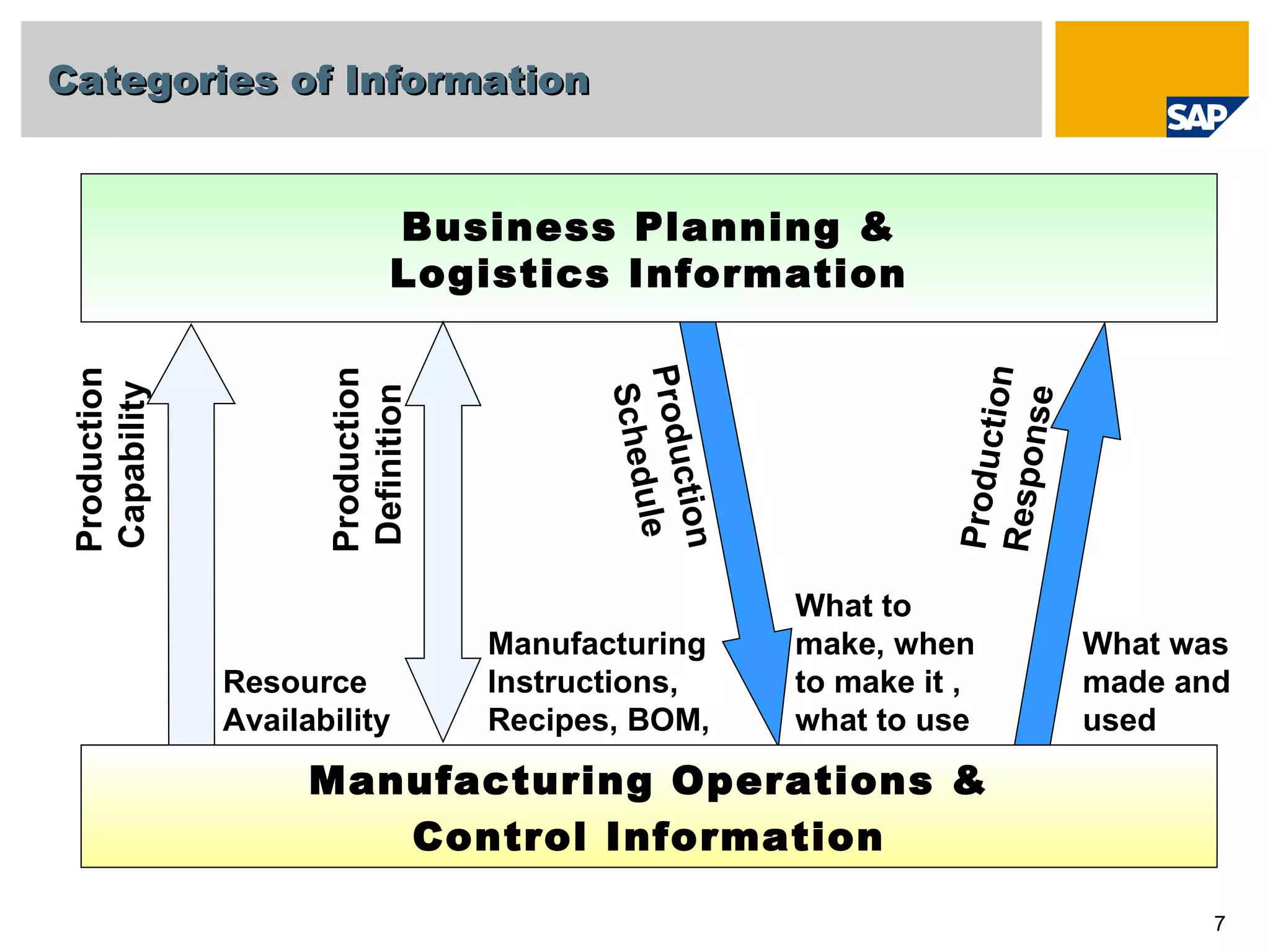

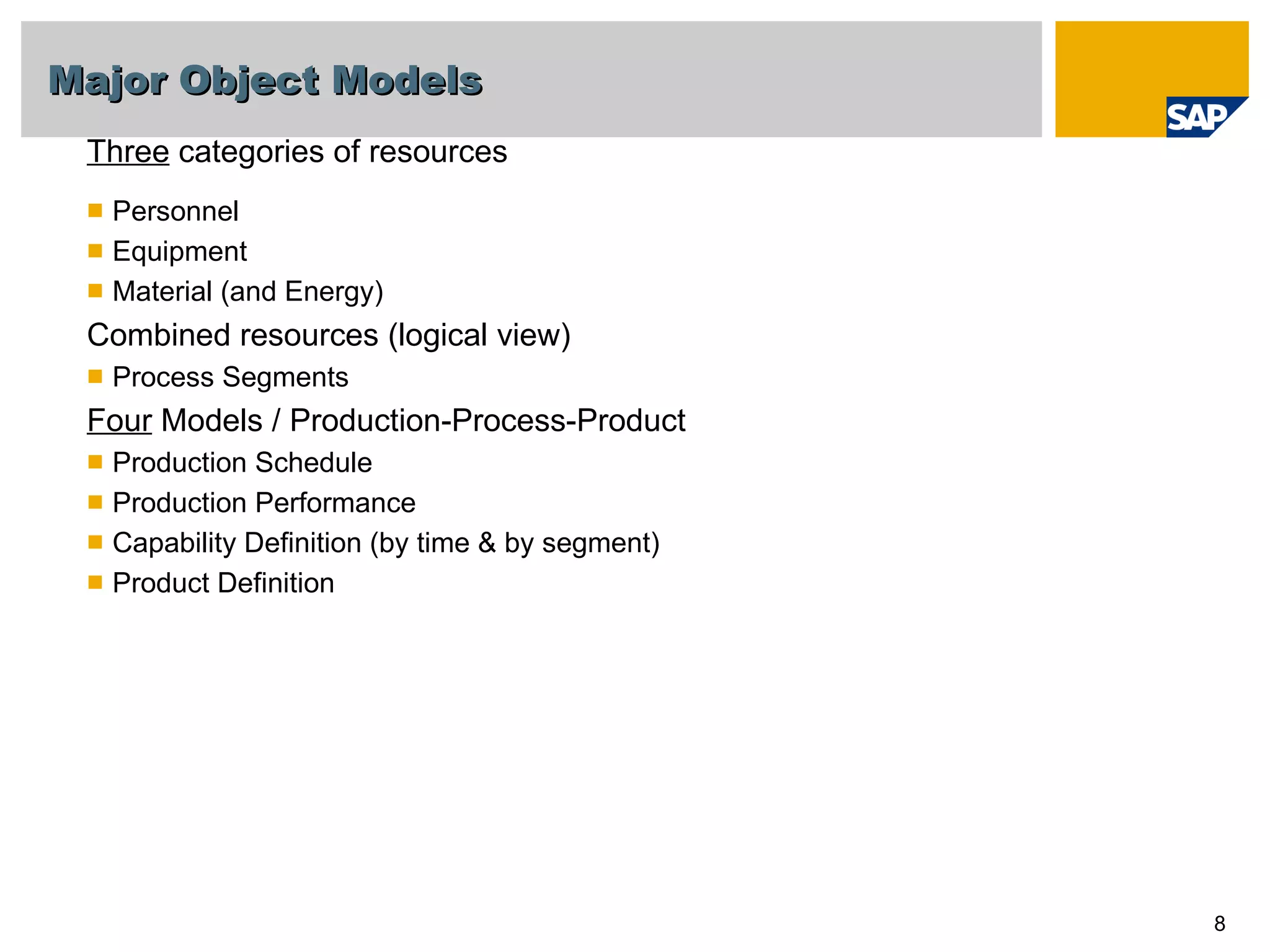

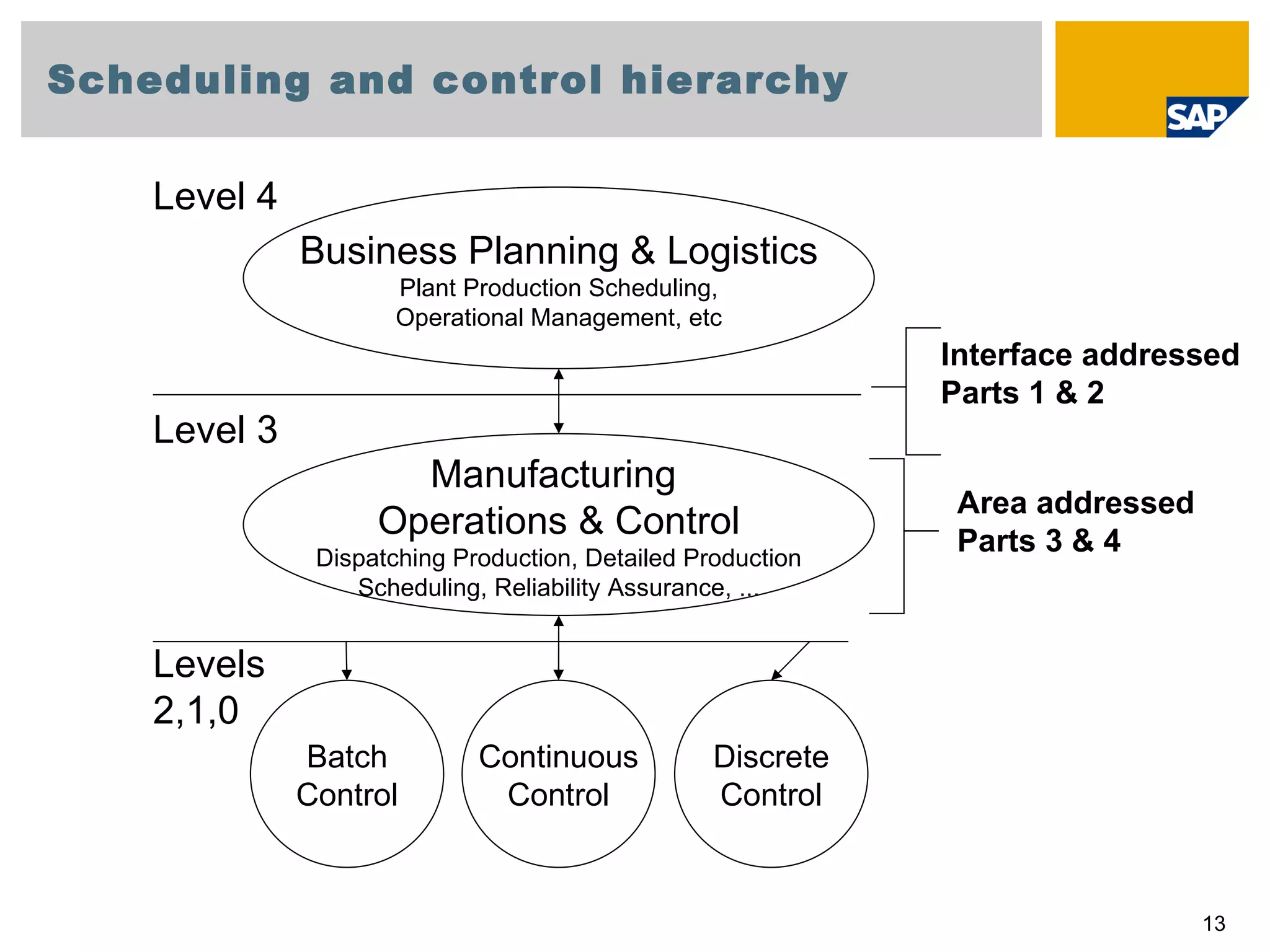

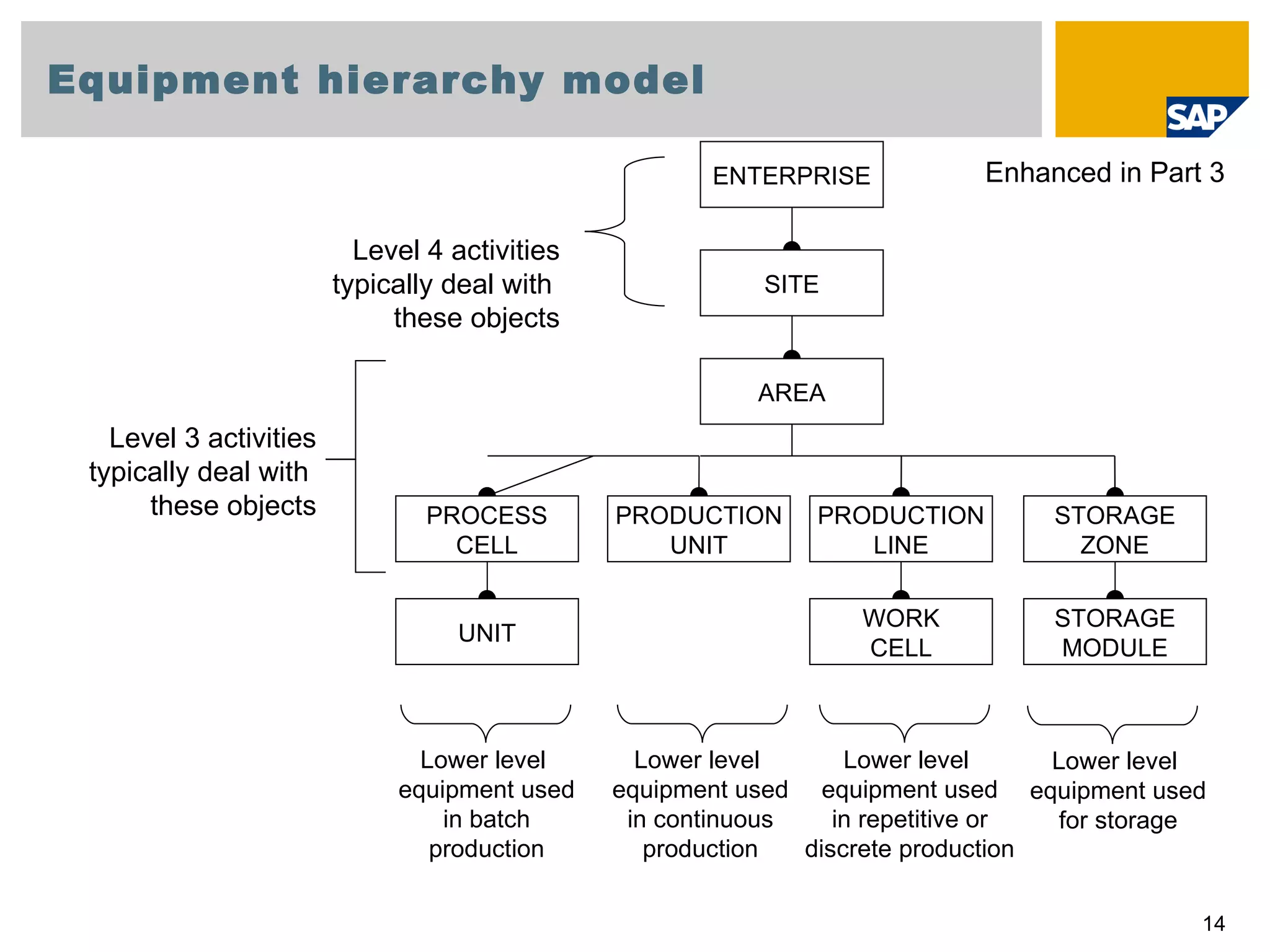

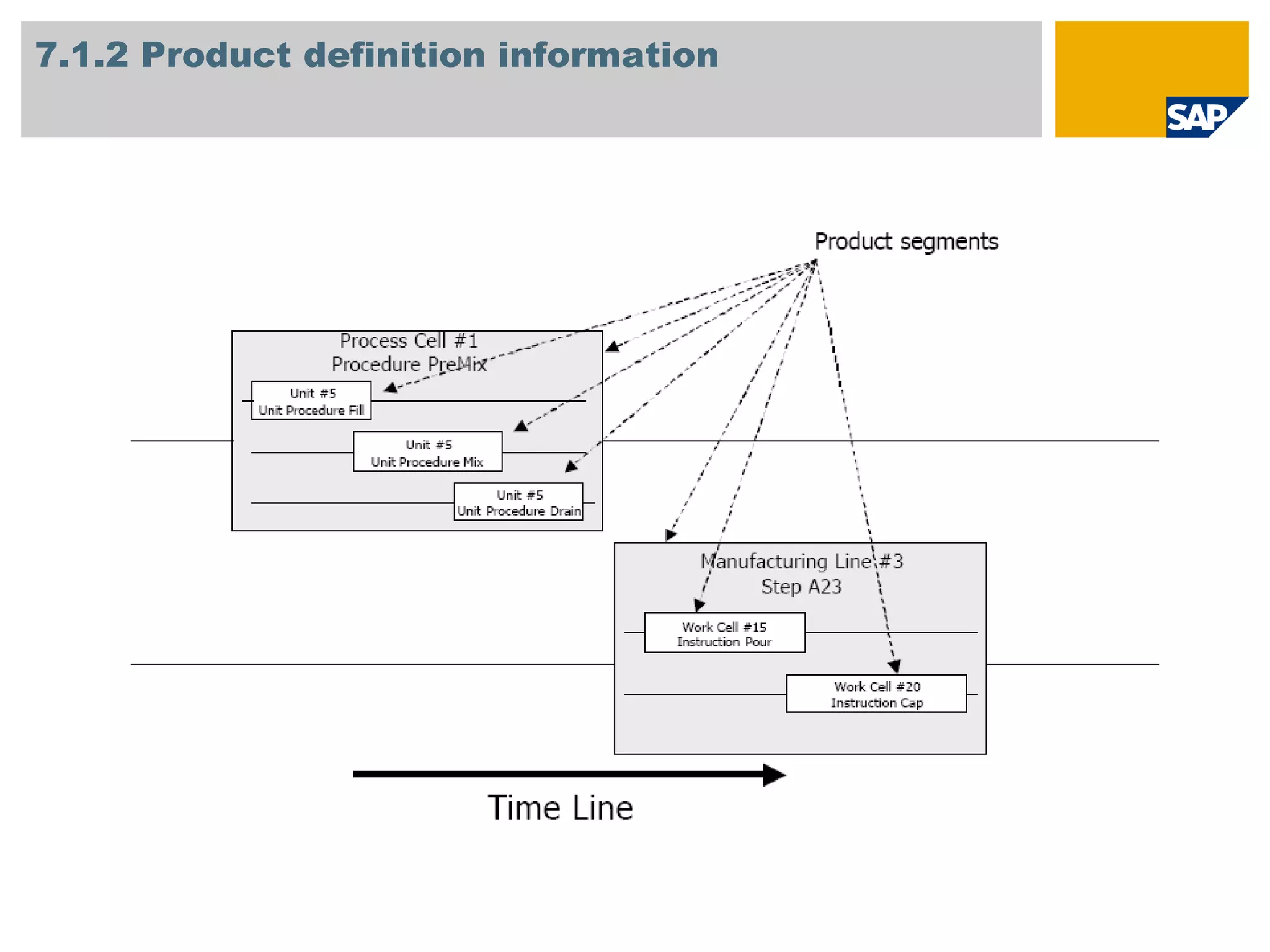

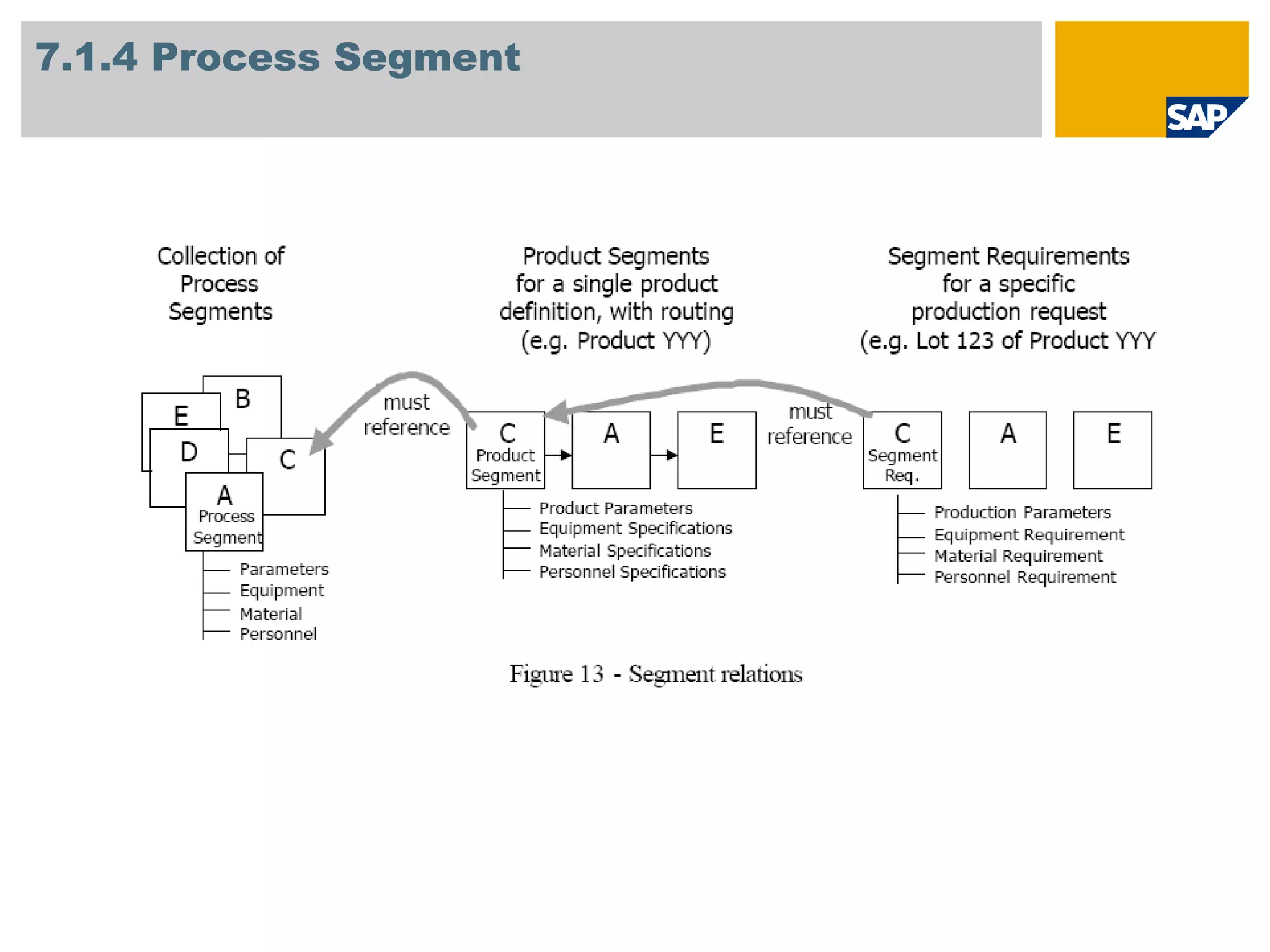

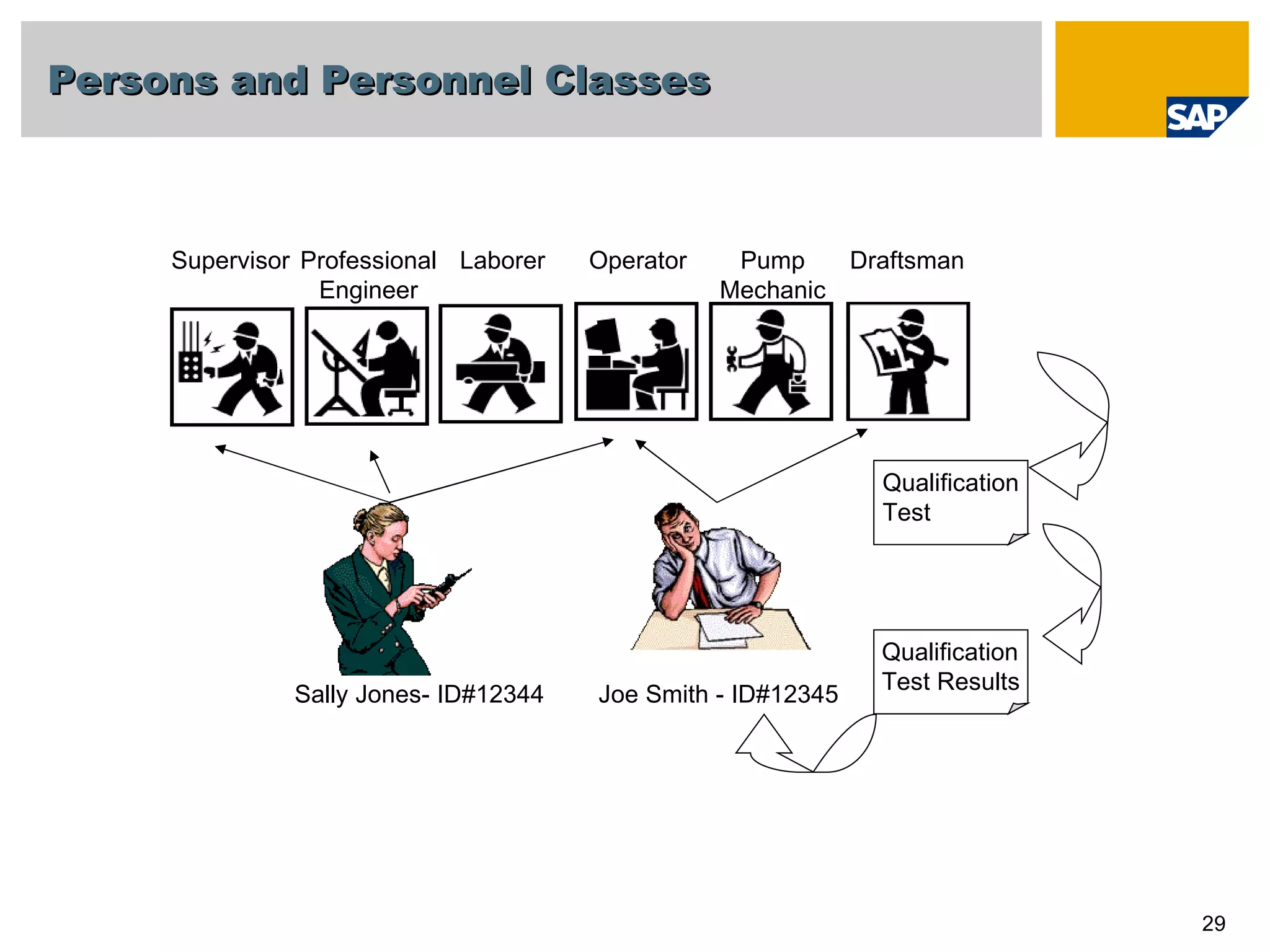

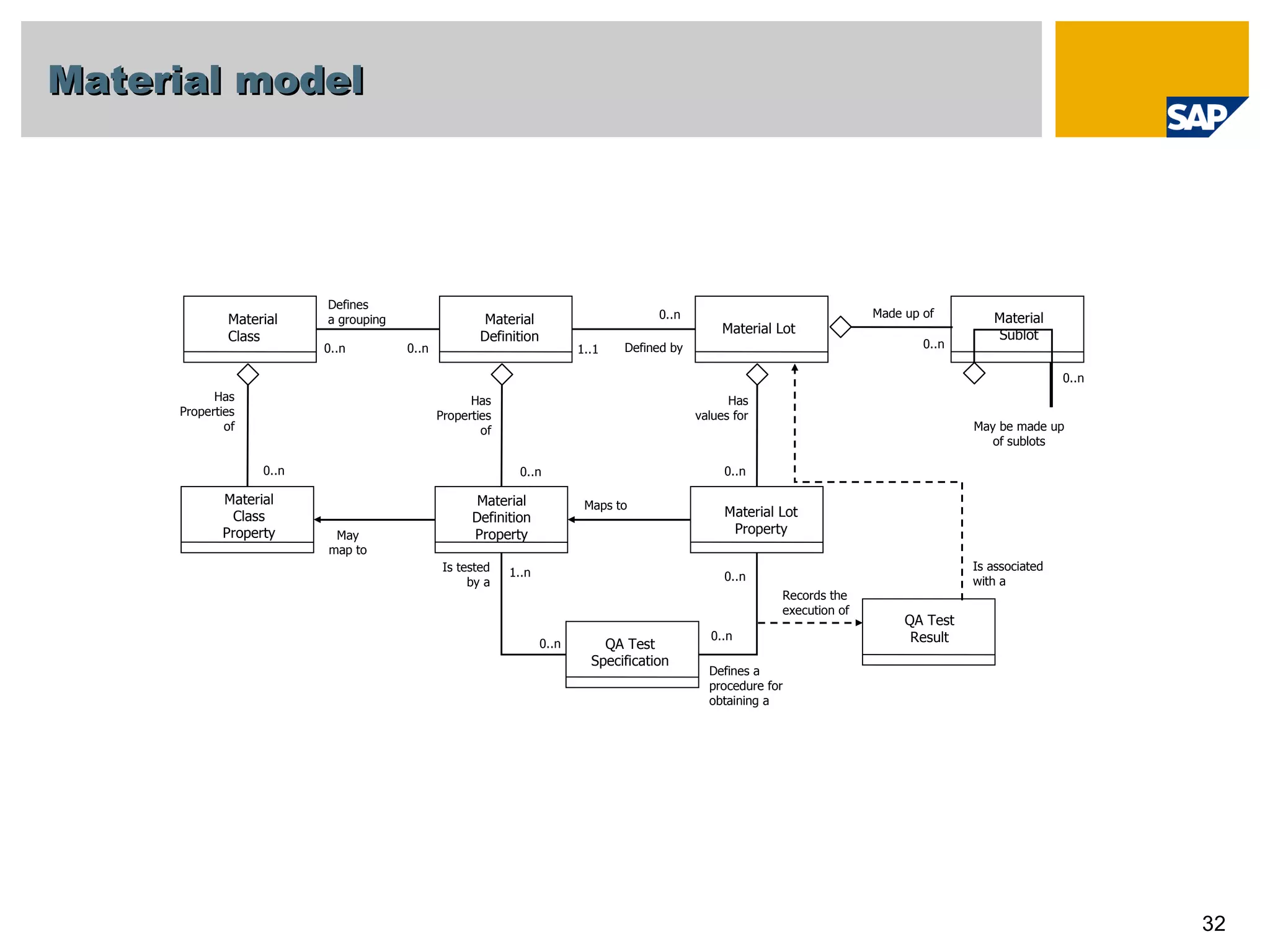

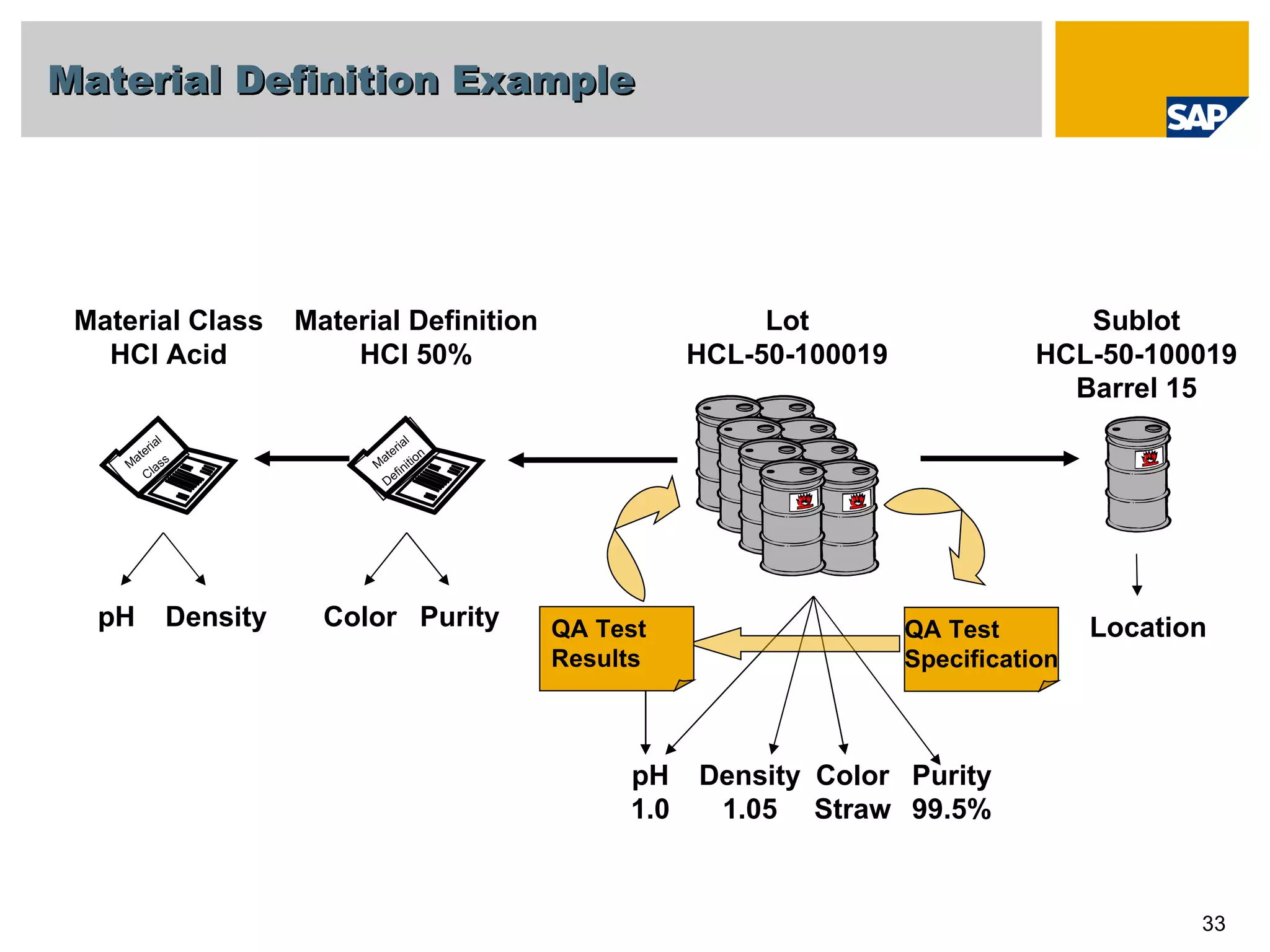

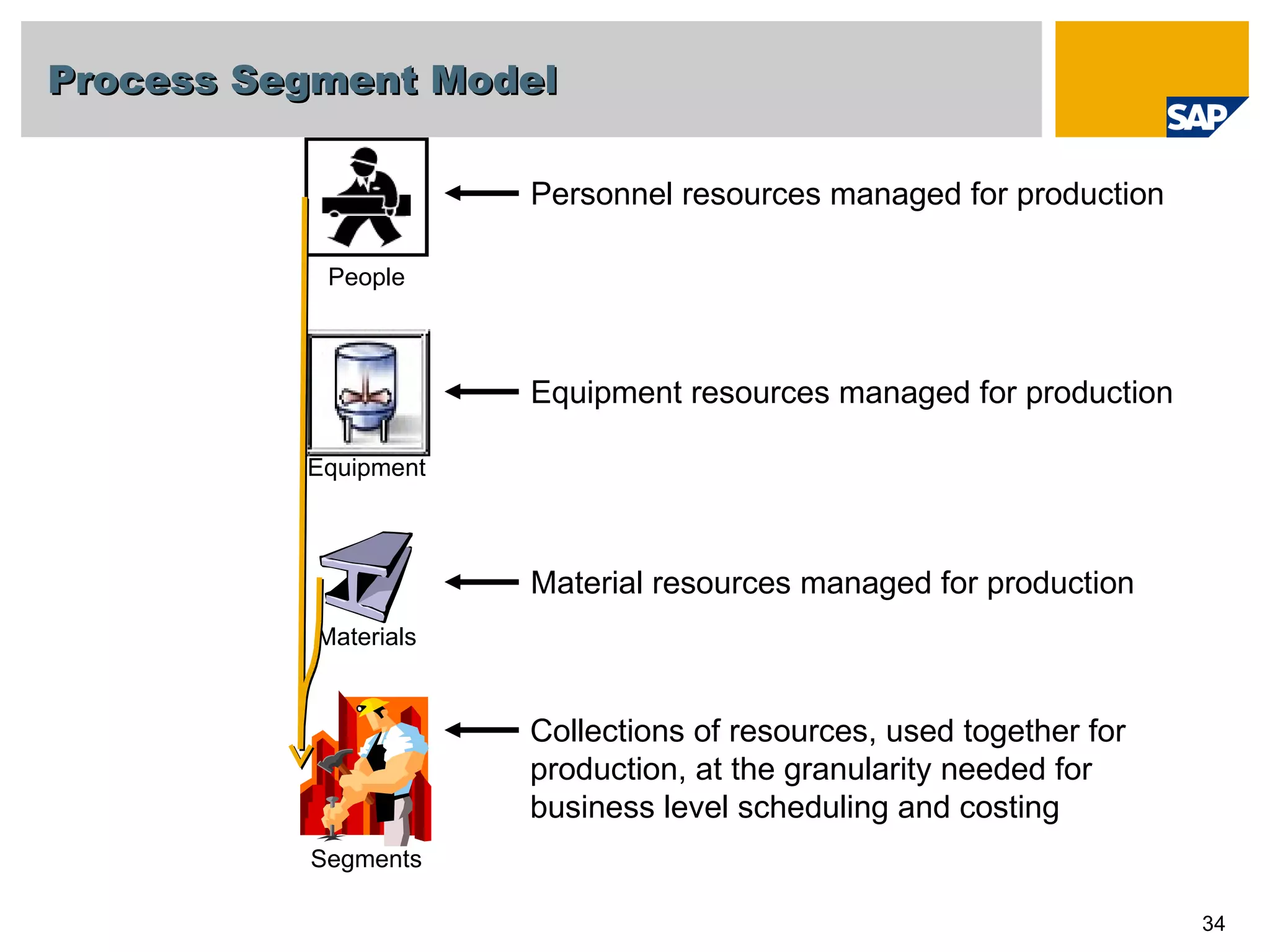

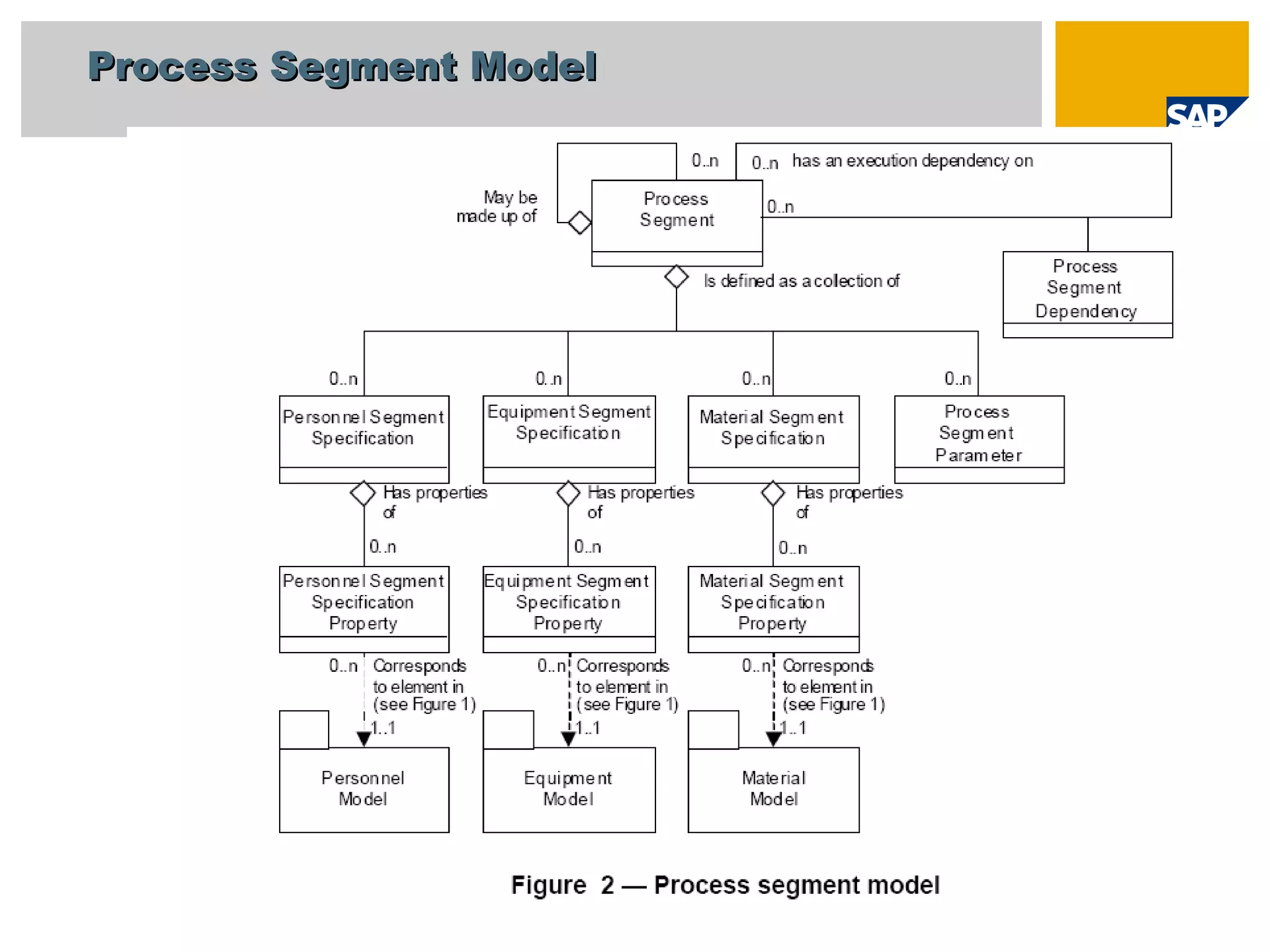

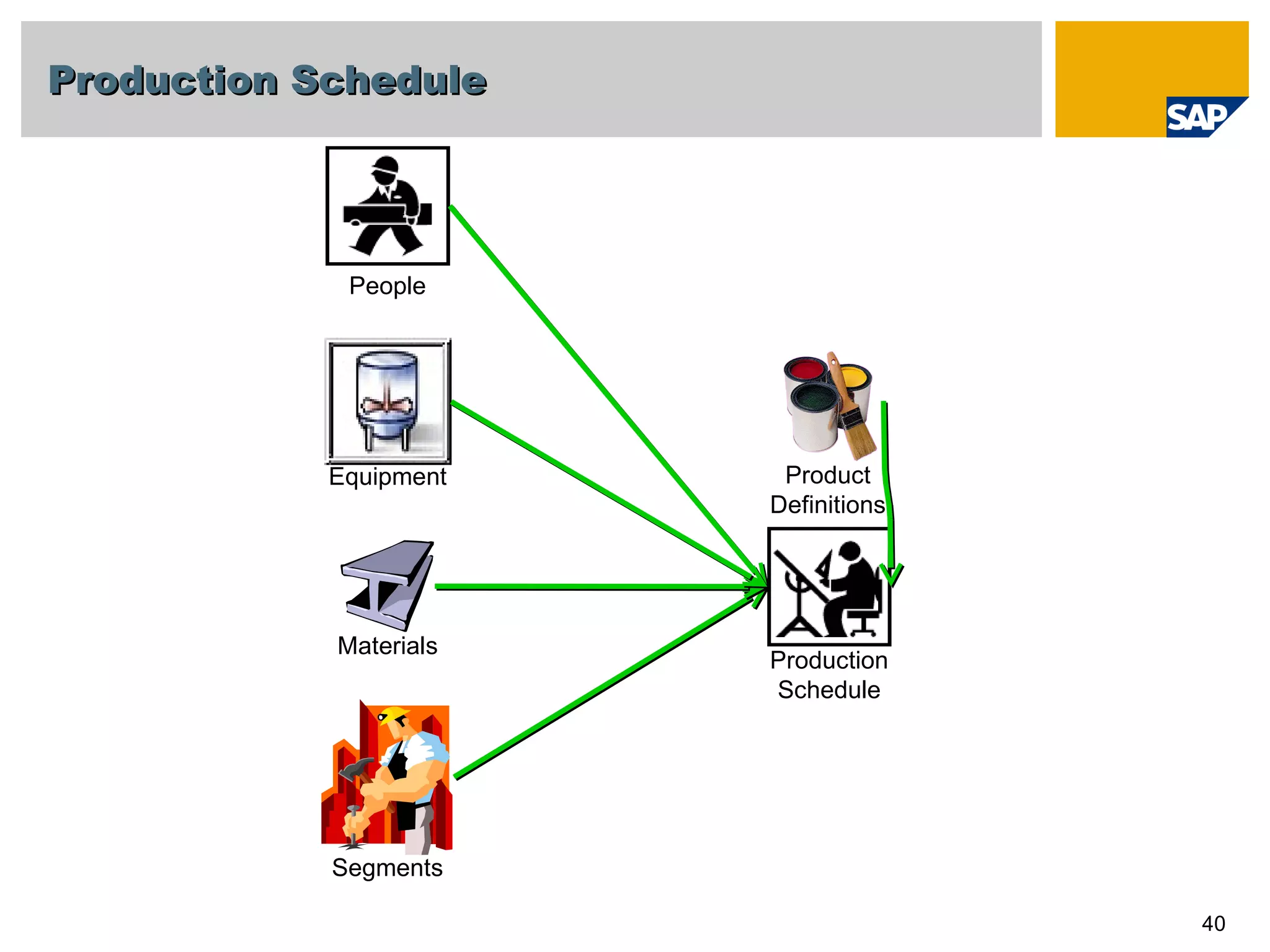

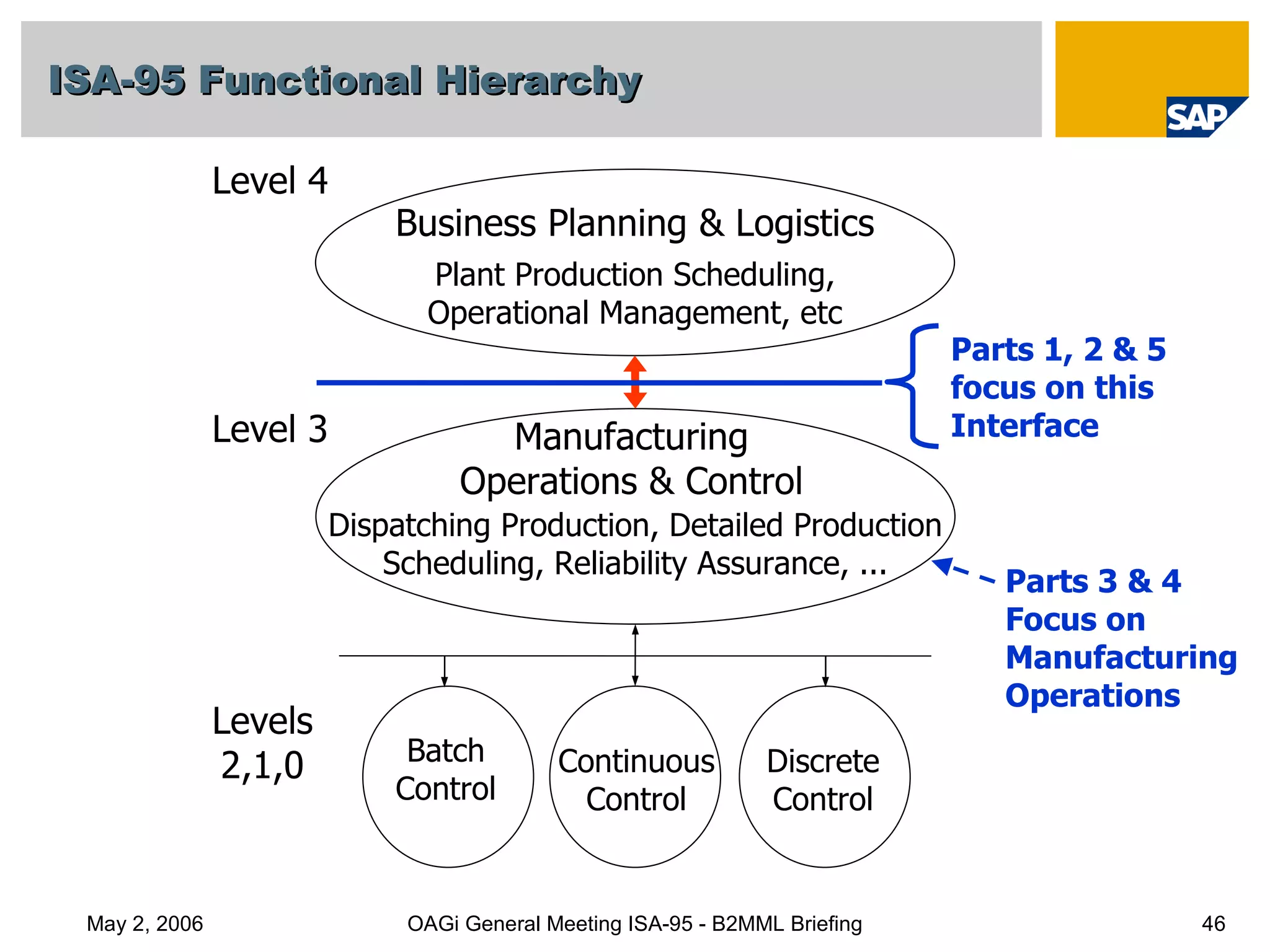

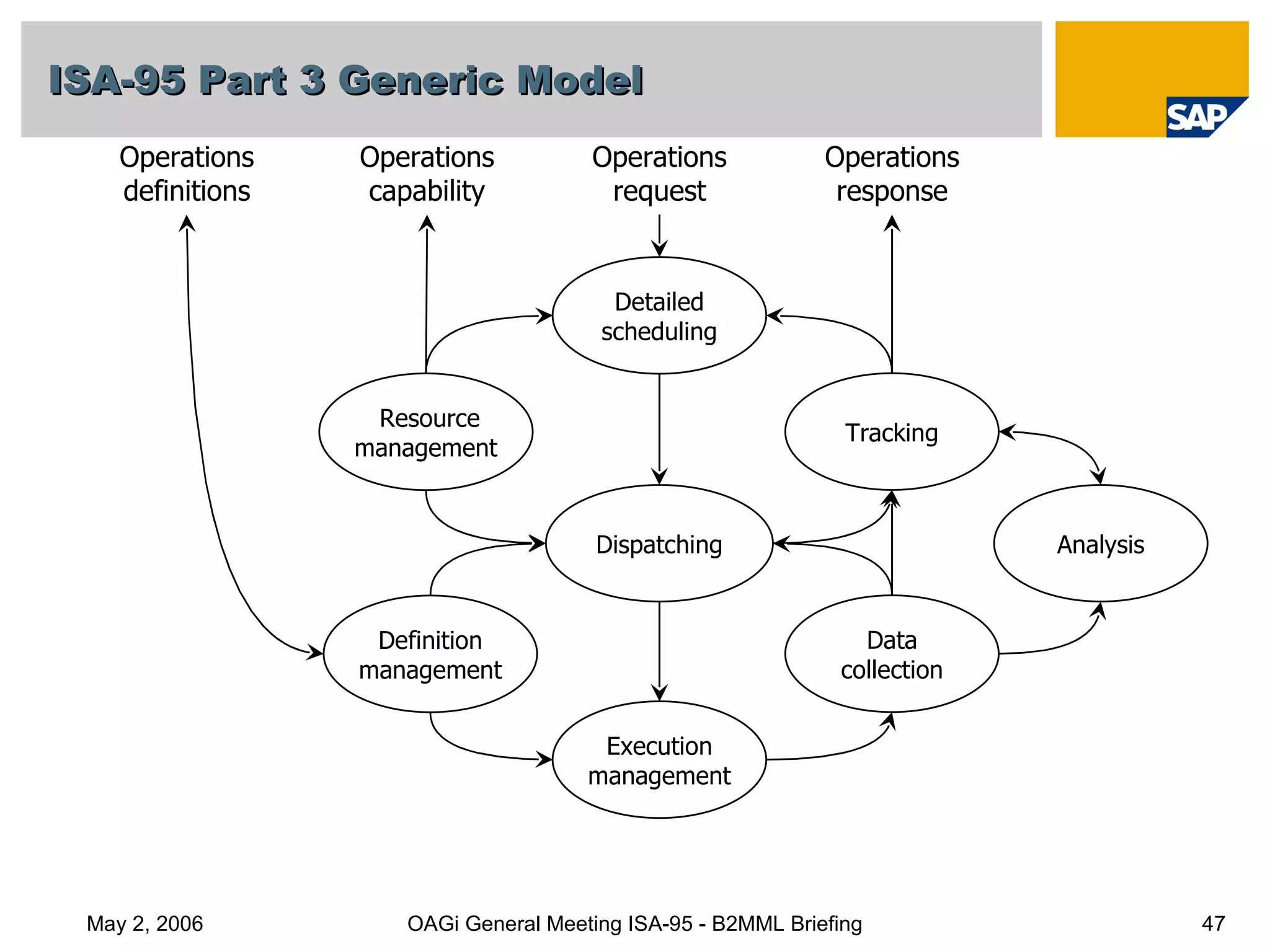

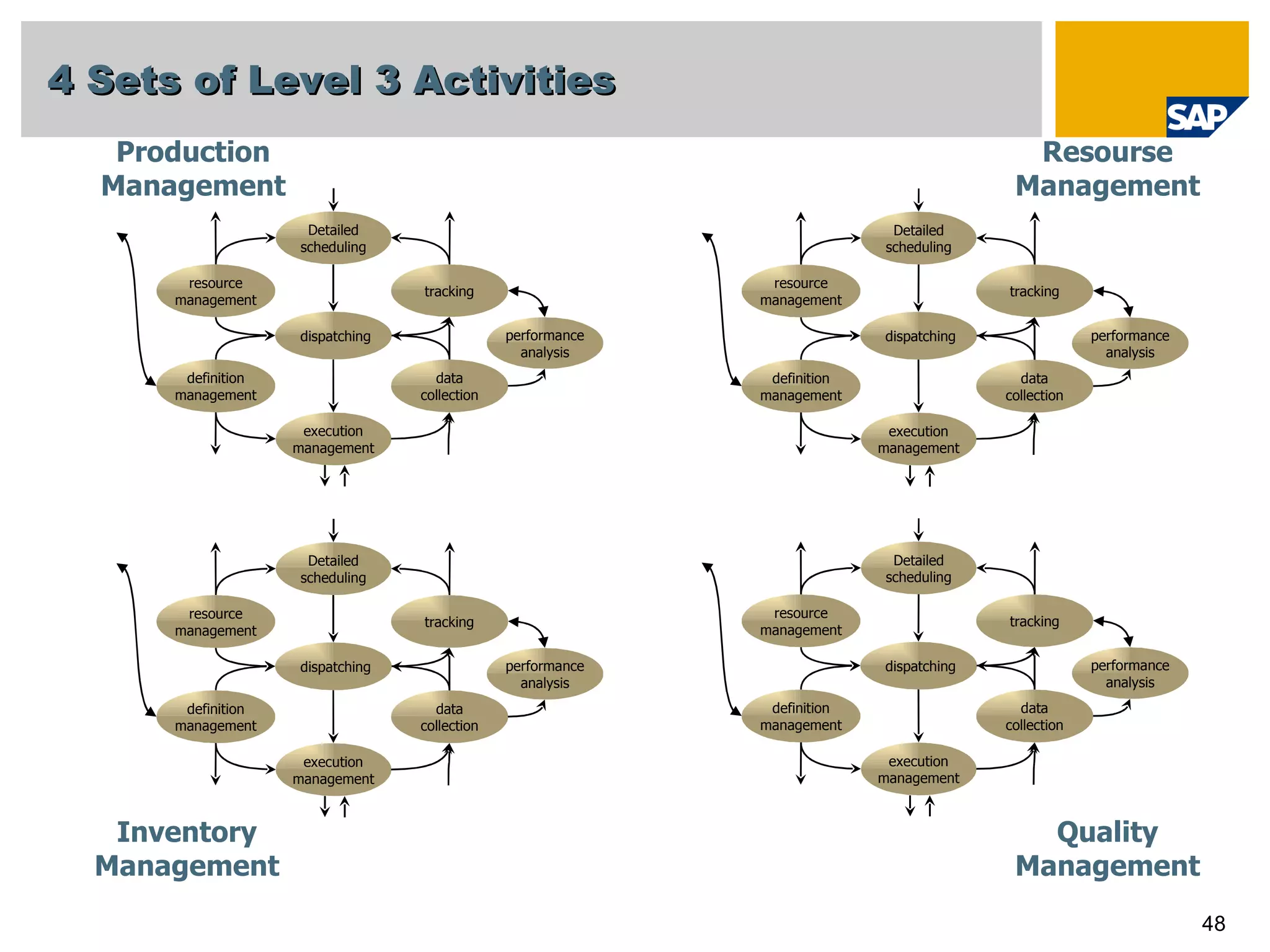

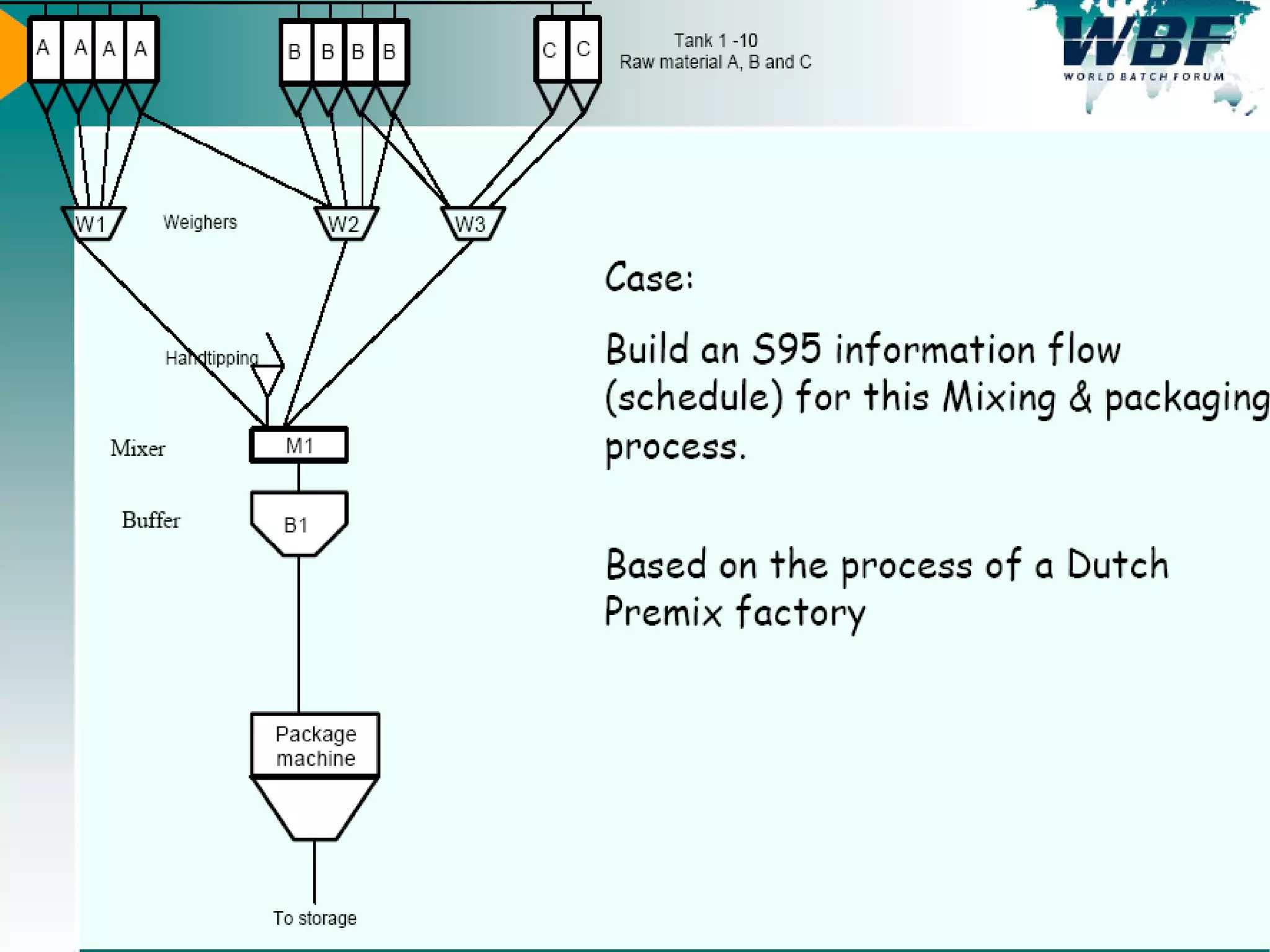

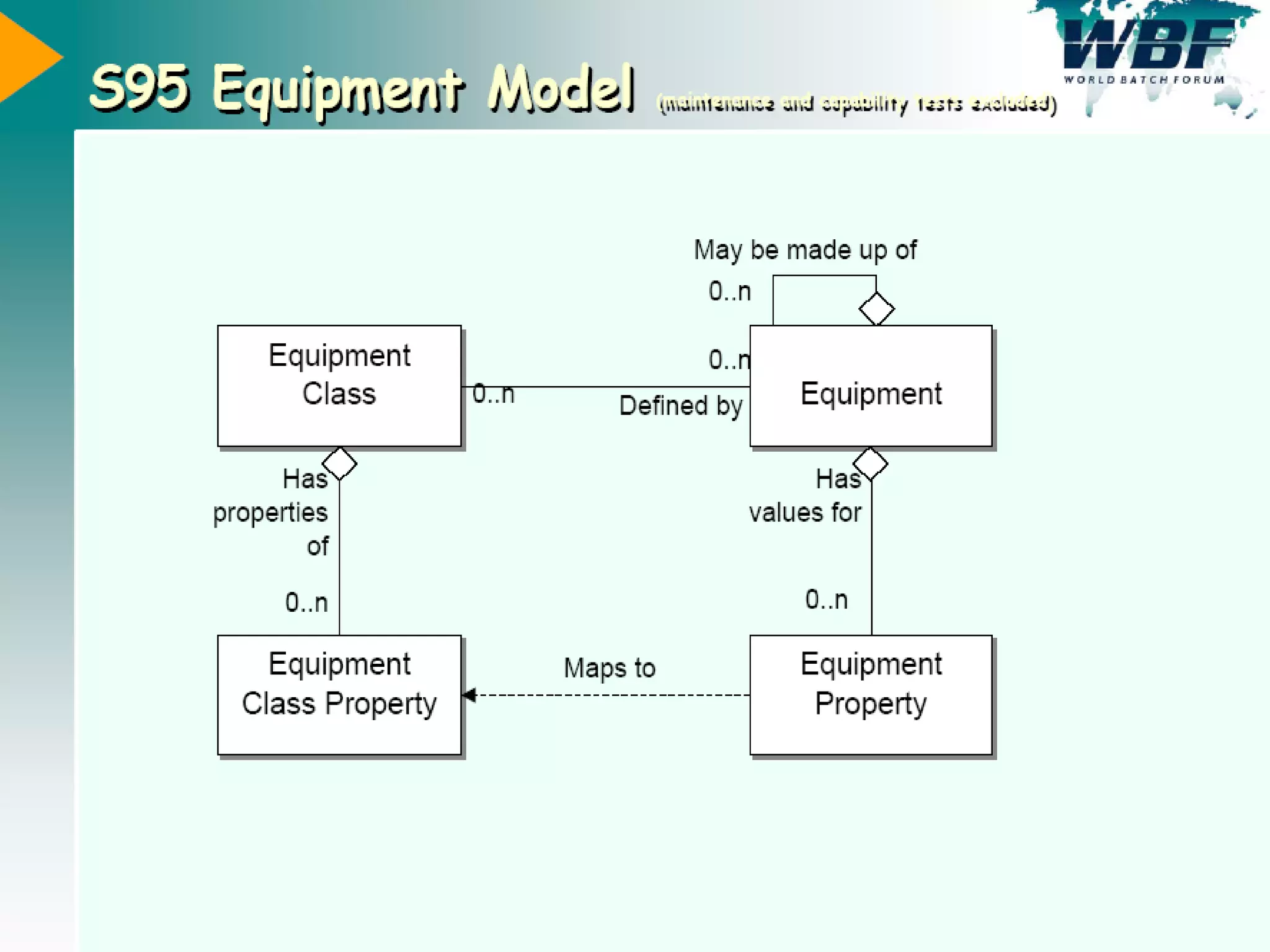

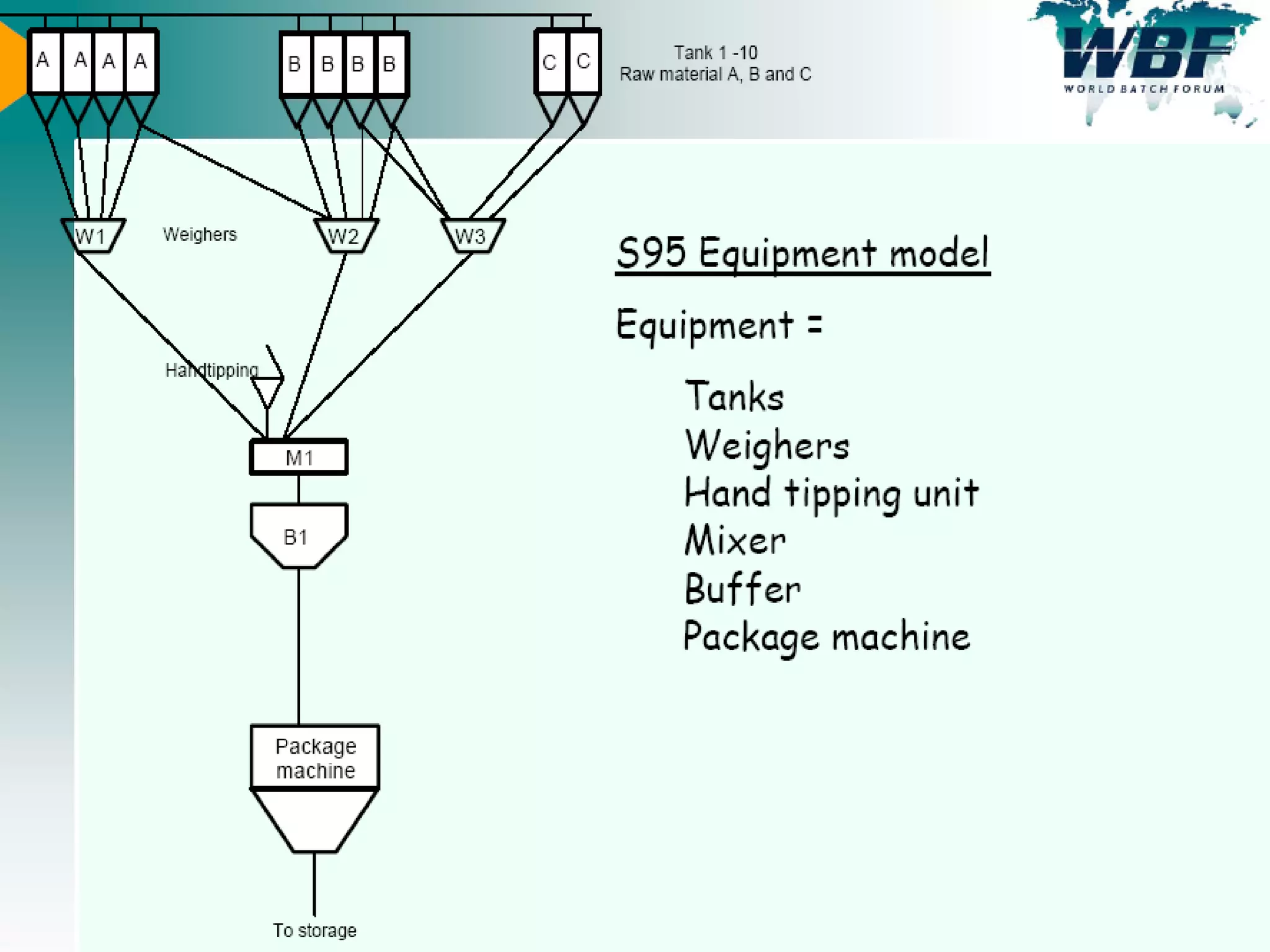

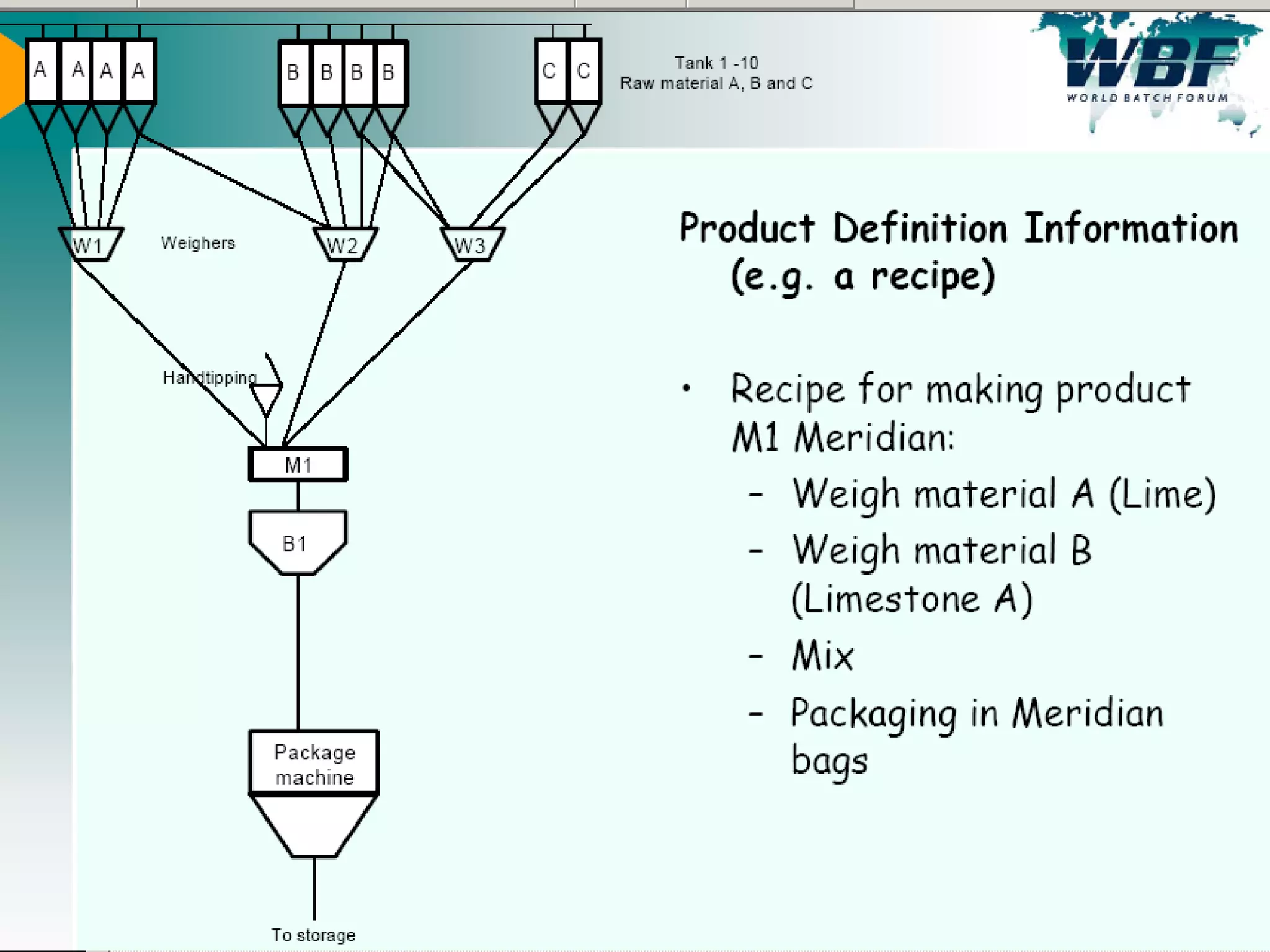

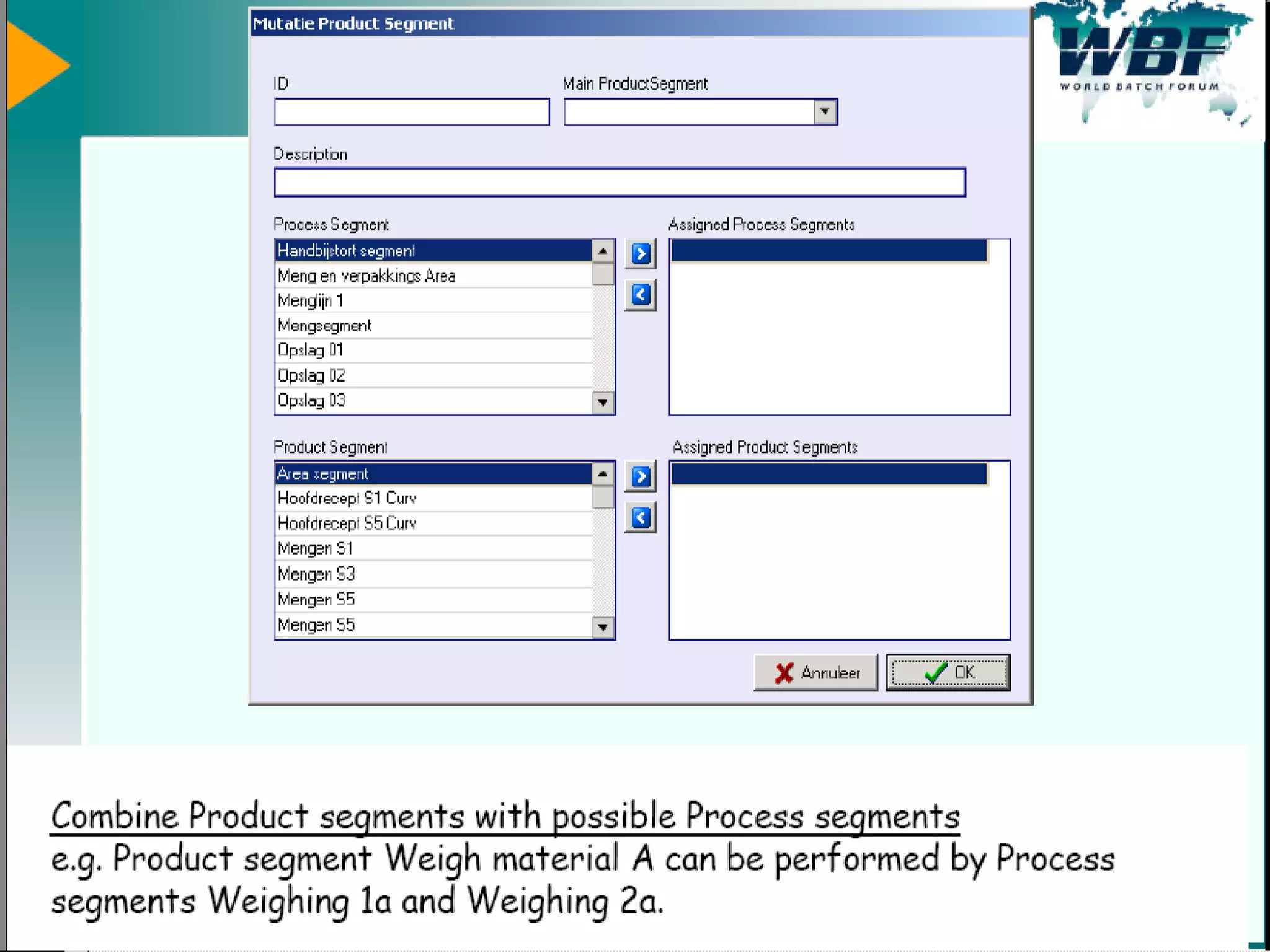

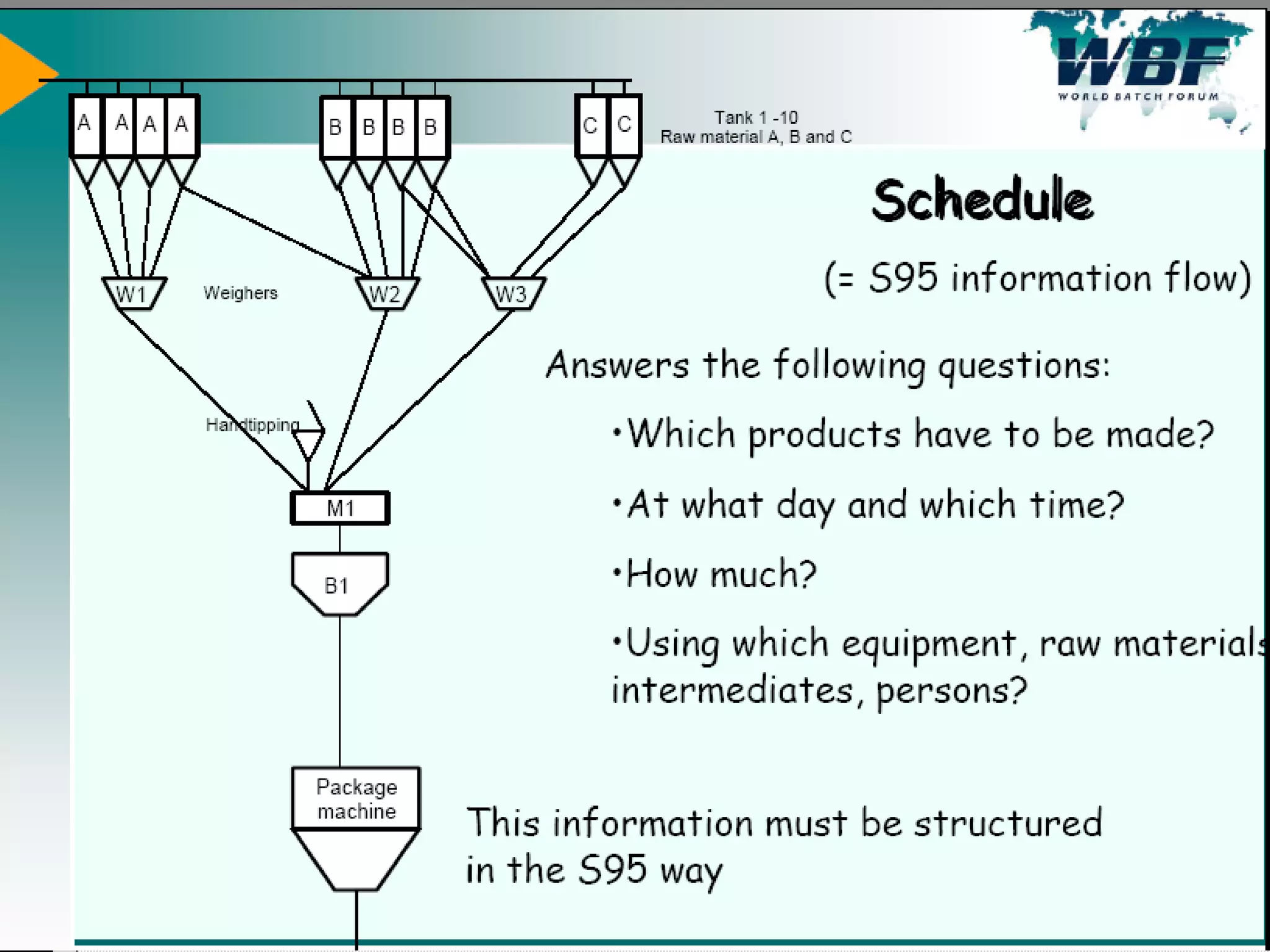

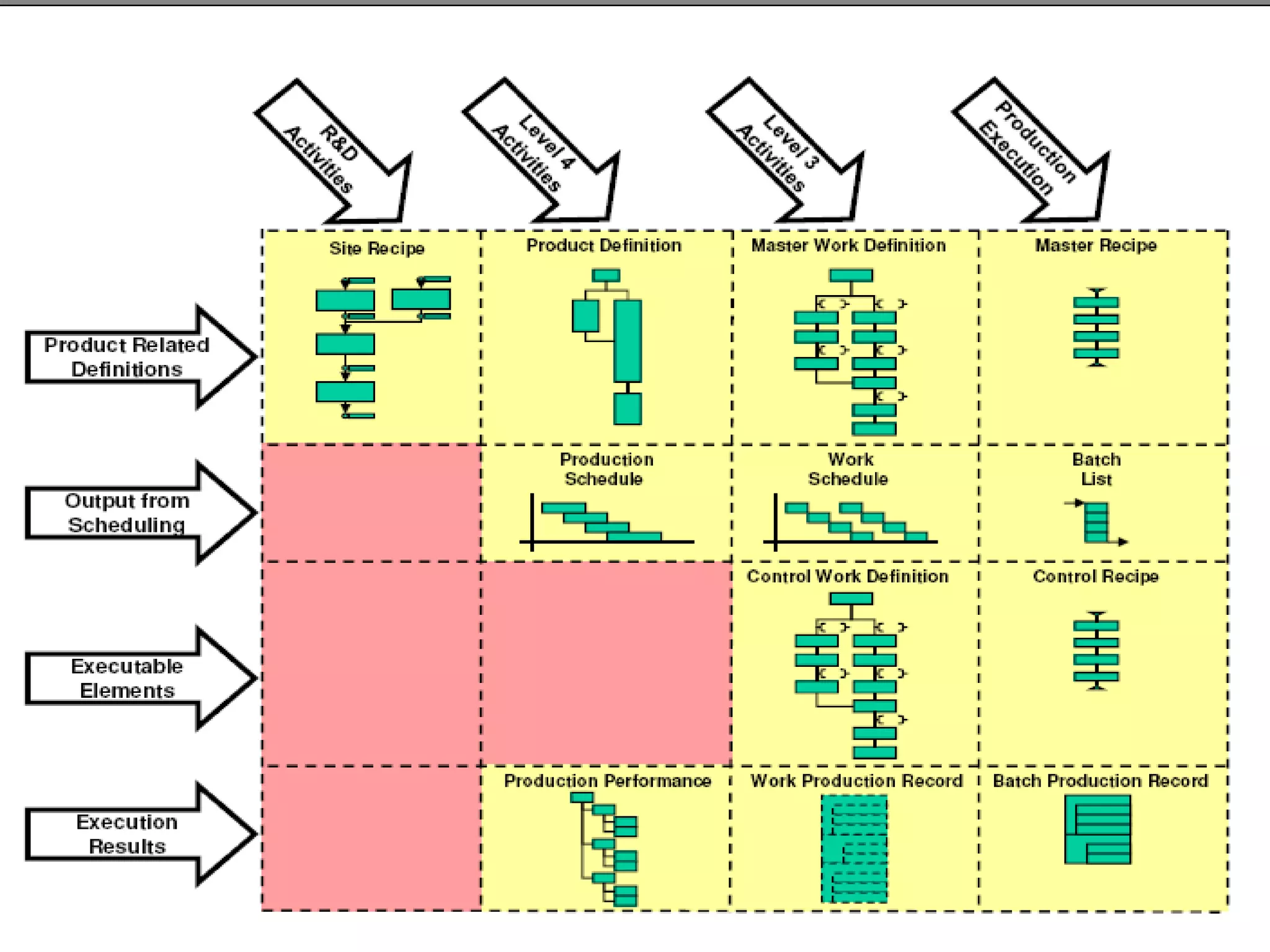

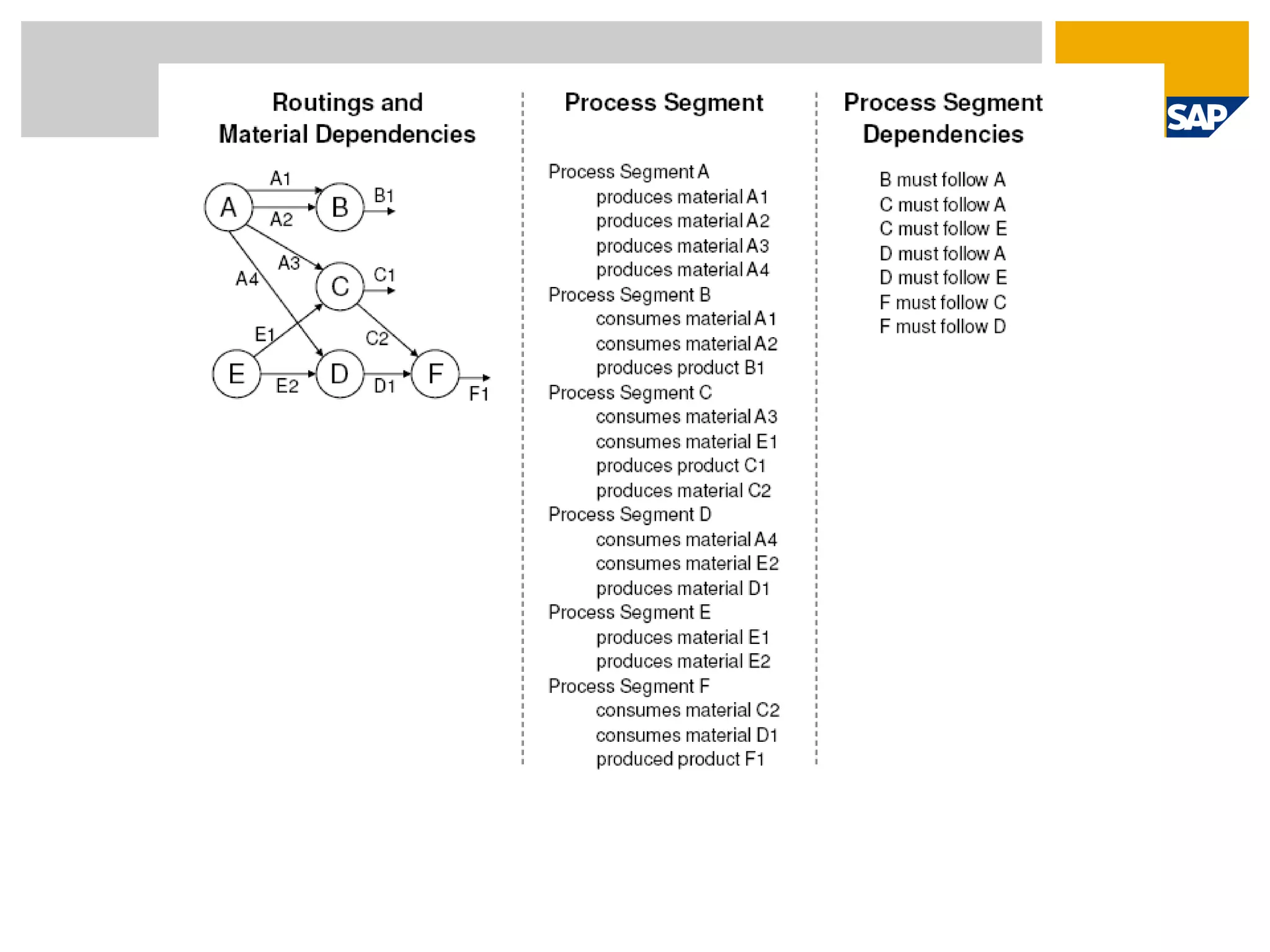

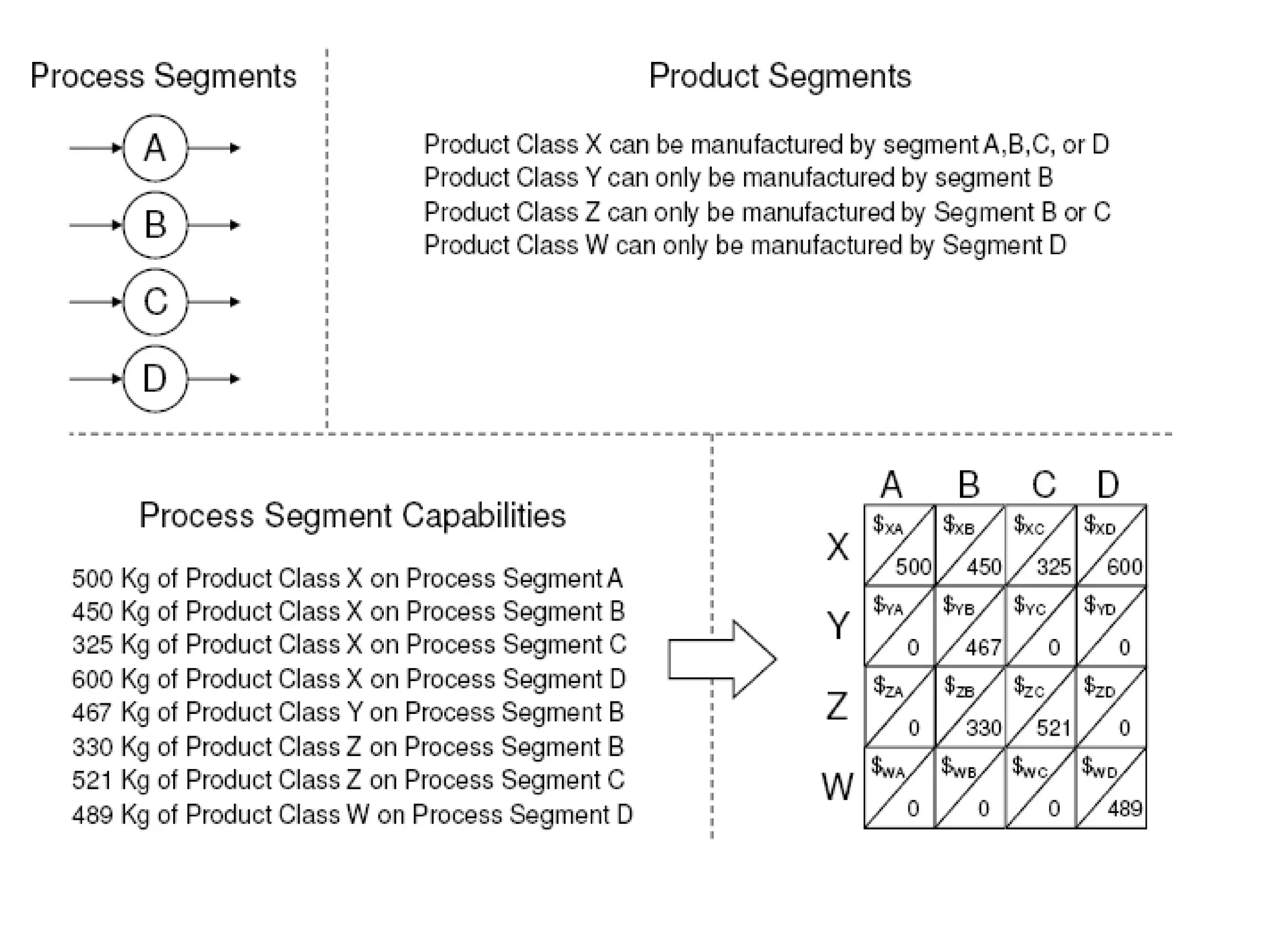

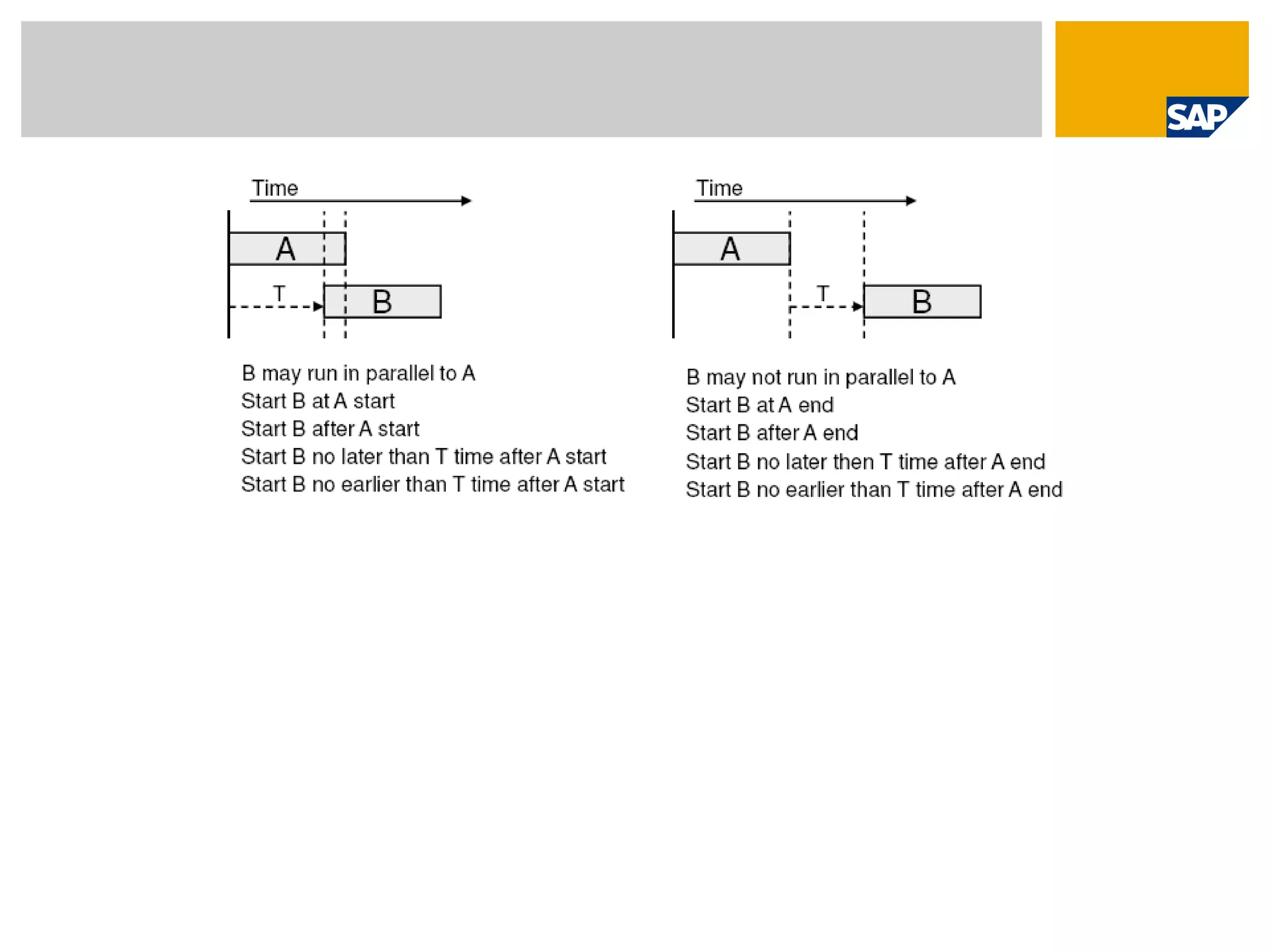

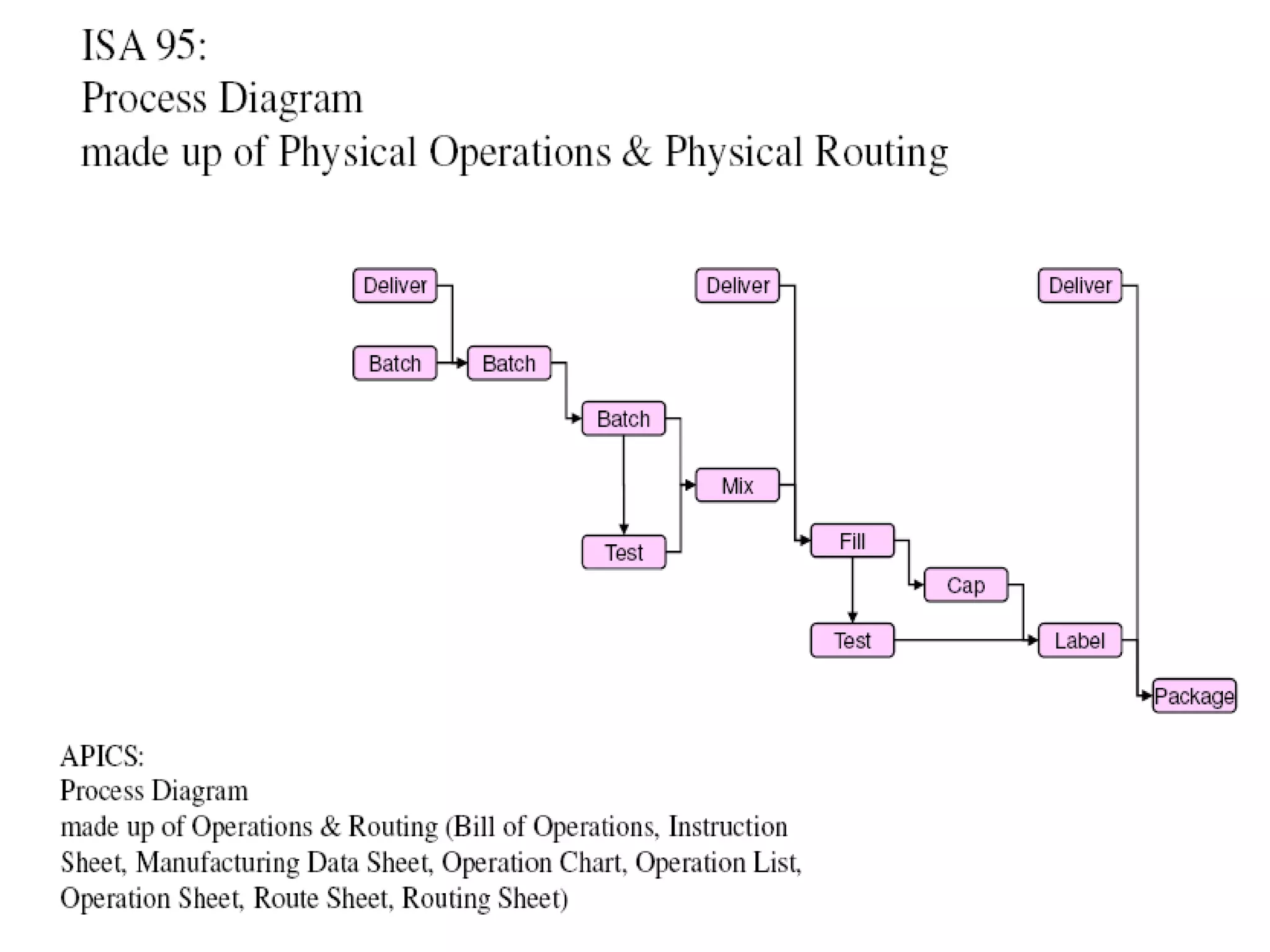

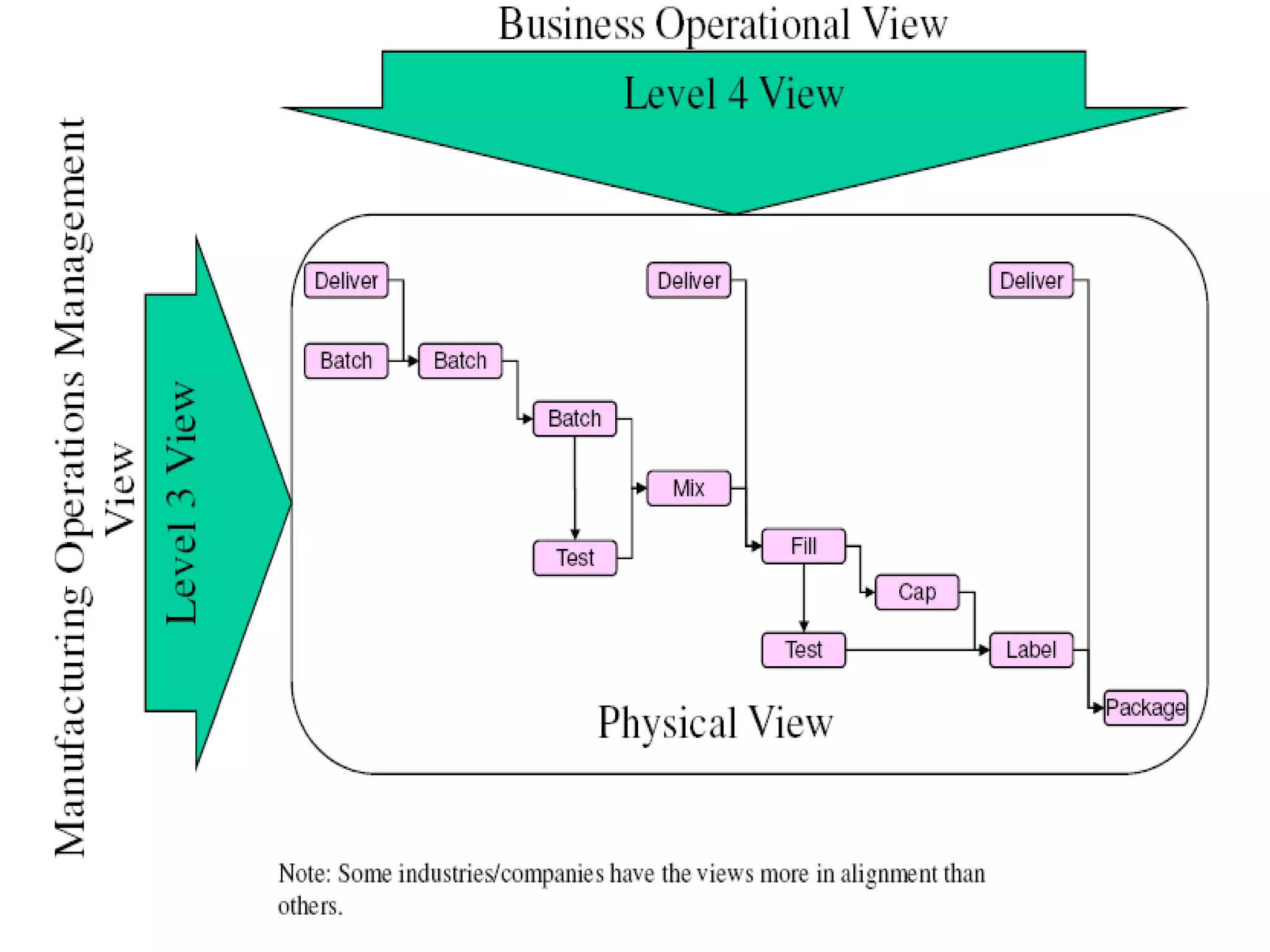

ISA-95 is a standard for integrating business and manufacturing systems. It provides a framework for integration projects by separating business and manufacturing processes. The standard defines object models for resources, production schedules, capabilities and more. It aims to enable information sharing across different automation and IT systems to improve supply chain optimization and other business needs.