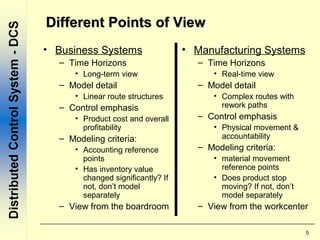

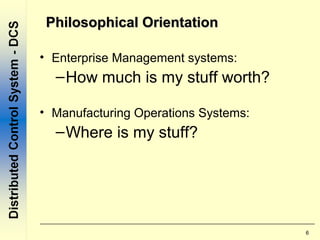

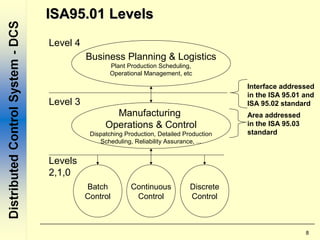

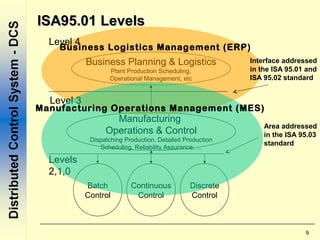

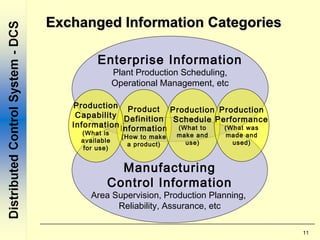

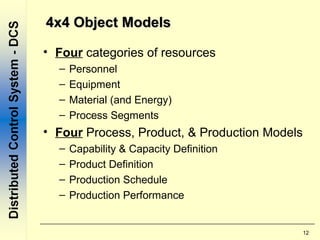

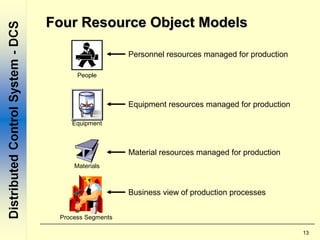

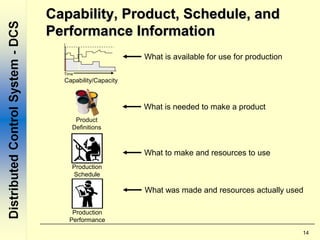

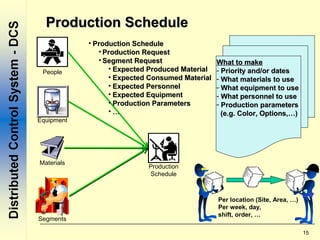

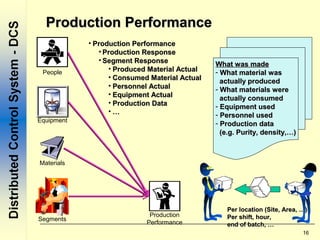

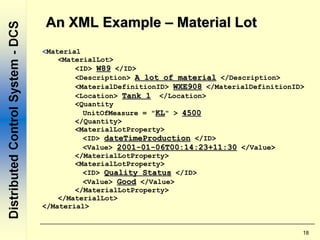

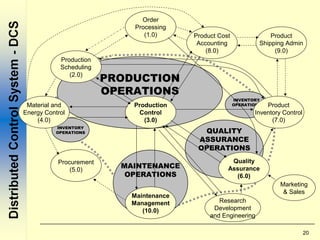

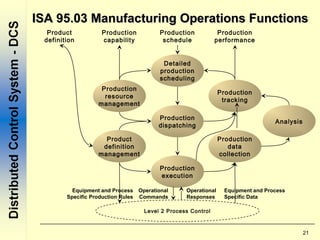

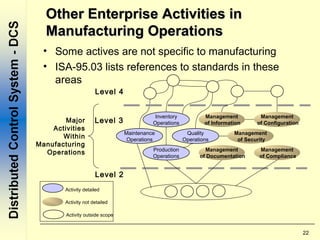

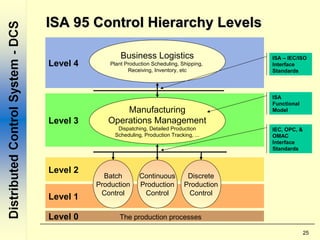

The document discusses the ISA 95 standards for integrating business systems with manufacturing systems. It provides an overview of the ISA 95 models including the four levels of the manufacturing hierarchy and the four object models for resources, capabilities, products, and production performance. The standards define the information that crosses the boundary between business and manufacturing systems. Implementations of the standards at various companies are also discussed.